Unifit Fasteners is a manufacturer and supplier of quality grade Nickel 200 / 201 Hex Nuts that are of superior quality in terms of strength and hardness particularly when cold worked. Nickel UNS N02200 Hex Nuts are considered to have excellent performance among formable cobalt alloy and can be used in continuous service up to 1800 o F. These alloys are among the most documented materials owing to their long history of use and reliability in different conditions and therefore they are studied widely to understand their behaviour under different conditions. However, like many high-performance alloys, prolonged exposure to mid-range temperatures can lead to reduced ductility at room temperature.

Nickel Alloy 201 Hex Nuts, Nickel 200 Hexagonal Nut, Alloy 200 Hex Nuts, Nickel 201 Hex Head Nut, ASTM B160 Nickel 201 Heavy Hex Nut Price in India.

Request QuoteTable of Contents

- What is Nickel 200 Hex Nuts?

- Technical Overview of Nickel 200 / 201 Hex Nuts

- Types of Nickel 200 Hex Nuts

- Nickel 200 Hex Nuts Weight Chart

- Material Specification Chart

- Equivalent Grades

- Chemical Composition

- Mechanical Properties

- Hex Nuts Dimensions Chart

- Heavy Hex Nut Dimensions Chart

- Machine Screw Hex Nut Dimensions Chart

- Hex Jam Nut Dimensions Chart

- Hex Nut Tolerance Chart

- Hex Nuts Thickness Chart

- Temperature Resistance

- Applications

- Price List

- Why Choose Unifit Fasteners?

- Leading Manufacturer, Supplier & Exporter

- FAQ’s About Nickel 200 Hex Nuts

What is Nickel 200 Hex Nuts?

Nickel 200 Hex Nuts are fastening components made from pure wrought nickel (UNS N02200) known for its exceptional resistance to corrosive environments, high thermal stability & good mechanical properties. These nuts are designed with a six-sided hexagonal shape which allows for easy tightening using standard wrenches or spanners to be used for secure & durable assemblies. It offers excellent resistance to alkalis, acids & salt solutions. It is non-magnetic making it suitable for sensitive applications where magnetic interference must be minimized.

Technical Overview of Nickel 200 / 201 Hex Nuts

Nickel 200 / 201 Hex Nuts will weld with GTAW, GMAW, SMAW, electron beam and resistance welding but not submerged arc welding. When proper joint fit-up is done, low interpass temperature and fast cooling take place, and the best results are guaranteed. To achieve maximum ductility, annealing of components at temperatures between 2150 and 2250°F with a fast cooling method must be used. The alloy has high resistance against both high-temperature oxidation and carburisation and works in environments that have hydrochloric acid, nitric acid, and wet chlorine.

Machining is typically smooth with no preference on stop milling, drilling and tapping. This material is best used with sulphur-chlorinated water-based cutting fluids. The alloy has a small increase in hardness and strength during aging of cold-worked parts, which makes them applicable in the area of high-temperature working, bearings and components with high galling resistance.

Nickel 201 Industrial Hex Nut, ASTM B160 Nickel 201 Machine Hex Nut, Alloy 201 Hexagonal Nylon Lock Nut, Nickel Alloy 200 Long Hex Nuts, UNS N02200 Hex Flange Nut, Alloy 200 Finished Hex Nut Stockist, 2.4066 Hex Nuts, Nickel Alloy 200 Hex Jam Nuts Supplier in Mumbai, India.

Types of Nickel 200 Hex Nuts

Nickel 200 Hex Nuts, made from pure nickel alloy (UNS N02200), offer excellent corrosion resistance, high thermal and electrical conductivity, and reliable mechanical strength. Selection depends on operating conditions like temperature, vibration, corrosive exposure, and installation requirements. They come in various types including heavyt hex nuts, hex jam nuts, hex lock nuts & hex wing nuts to suit different industrial needs.

- Nickel 200 T-Slot Nut

- Nickel 200 Thin Nuts

- Nickel 200 Wing Nuts

- Nickel 200 Nylon Lock Nut

- Nickel 200 Cap Nuts

- Nickel 200 Square Nuts

- Nickel 200 Coupling Nuts

- Nickel 200 Hex Jam Nuts

- Nickel Alloy 200 T-Nuts

- Nickel 200 Auto Lock Nuts

- Nickel 200 2-H Heavy Hex Nut

- Nickel 200 Miscellaneous Nut

- Nickel 200 Nylon Insert Lock Nuts

- Nickel 200 Serrated Flange Nuts

- Nickel 200 Hexagonal Nuts

- Nickel 200 Panel Nuts

- Nickel 200 Flex Lock Nuts

- Nickel 200 Pin Lock Nuts

- Nickel 200 Lug Nuts

- Nickel Alloy 200 Eye Nuts

- Nickel 200 High Tensile Nuts

- Nickel 200 Cage Nuts

- Nickel 200 Dome Nuts

- Nickel 200 Knurled Nuts

- Nickel 200 Keps-K Lock Nuts

- Nickel 200 Machine Hex Nut

- Nickel 200 Slotted Nuts

- Nickel 200 Knurled Nuts

- Nickel 200 Hex Jam Nuts

- Nickel 200 Lifting Eye Nuts

- Nickel 200 Sleeve Nuts

- Nickel 200 Imperial Nuts

- Nickel 200 Rivet Nuts

- Nickel 200 Castle Nuts

- Nickel 200 Weld Nuts

- Nickel 200 Cage Nuts

- Nickel 200 ACME Nuts

- Nickel 200 High Nuts

Send Your Enquiry

Why Choose Unifit Fasteners?

At Unifit Fasteners, top nickel 200 hex nuts manufacturer & supplier, combine cutting-edge technology, rigorous quality control & customer centric solutions to deliver unmatched value in every product we manufacture.

- Quality & Testing Facilities: We are an ISO-certified company committed to maintaining the highest standards in quality management. Each product undergoes strict inspections from material control & visual checks to lab testing & certification. Provide mill & manufacturer test certificates as per EN 10204 3.1 / 3.2 conforming to NACE MR 0175 standards.

- Customize Size & Specification: We offer customized solutions to provide the products with flexibility in sizes, shapes & designs to meet diverse project requirements to follow standards.

- Competitive Pricing: Using in-house manufacturing facilities including welding, machining & mandrel processing, we maintain cost efficiency without compromising on quality. This allows us to offer budget-friendly prices with top-grade performance.

Nickel 200 Hex Nuts Weight Chart

Explore the detailed weight chart for Nickel 200 hex nuts across multiple configurations including Finished Hex, Heavy Hex, Jam, Square & Heavy Square types. The chart given below provides precise weight data (in grams) for various nut sizes from 1/2" & 1 to 5/8"to engineers, buyers & manufacturers. It is used to accurate load calculations & inventory planning.

| Size | Finished Hex | Heavy Hex | Finished Jam | Heavy Hex Jam | Square | Heavy Square |

|---|---|---|---|---|---|---|

| 1/2" Nut | 3.75 | 6.54 | 2.62 | 4.00 | 5.78 | 7.87 |

| 5/8" Nut | 7.33 | 11.9 | 4.93 | 6.96 | 10.8 | 14.3 |

| 3/4" Nut | 11.9 | 19.3 | 7.70 | 11.0 | 15.4 | 23.5 |

| 7/8" Nut | 19.0 | 29.7 | 12.0 | 16.7 | 24.5 | 36.2 |

| 1" Nut | 28.3 | 42.5 | 17.6 | 23.5 | 36.3 | 51.5 |

| 11/8" Nut | 40.3 | 59.2 | 24.7 | 32.4 | 52.5 | 72.4 |

| 11/4" Nut | 54.3 | 78.6 | 36.1 | 45.8 | 70.6 | 95.5 |

| 13/8" Nut | 73.0 | 102 | 47.9 | 59.3 | 94.5 | 125.0 |

| 11/2" Nut | 94.3 | 131 | 60.9 | 74.8 | 122 | 161 |

| 15/8" Nut | 162 | 91.6 | ||||

| 13/4" Nut | 151 | 204 | 100 | 114 | ||

| 17/8" Nut | 241 | 134 | ||||

| 2" Nut | 224 | 299 | 140 | 165 | ||

| 21/4" Nut | 419 | 227 | ||||

| 21/2" Nut | 564 | 332 | ||||

| 23/4" Nut | 738 | 429 | ||||

| 3" Nut | 950 | 545 | ||||

| 31/4" Nut | 1194 | 651 | ||||

| 31/2" Nut | 1526 | 851 | ||||

| 33/4" Nut | 1812 | 1005 | ||||

| 4" Nut | 2180 | 1200 |

Material Specification Chart of Nickel Alloy 200 / 201 Hex Nuts

| Specifications | Details |

|---|---|

| Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Length | 3 mm to 200 mm |

| Hex Nuts | UNF, BSW, BSF, METRIC, UNC, or as required |

| Standard |

DIN : DIN 934, DIN 931, DIN 970, DIN 933 UTS : UNEF, NPT, UNC, UNS, UNF, NPTF ISO : JIS standards, ISO 4033, ISO 4032, ANSI – American National Standards Institute ASME B18.5 ANSI B 28.2.4 1M ANSI B 18.2.4 2M as per defined in ASME B18.2.2 Hex nuts |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Production process | M24-M100: hot forging , M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Head drive | Six-Lobe,Phillips,Phillips/Slot, Slotted etc |

| Surface Coating | Ptfe Coated Nuts Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating |

| Finishing | Coatings & Finishes : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide |

Equivalent Grades of Nickel Alloy 200 / 201 Hex Nuts

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 |

Nickel Alloy 201 / 201 Hex Nuts Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Alloy 200 / 201 Hex Nuts Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 200 / 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

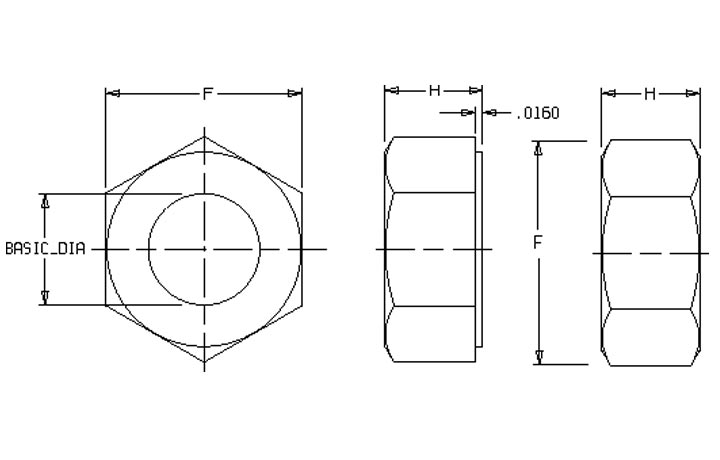

Nickel 200 Hex Nuts Dimensions Chart

This dimension chart offers precise measurements for Nickel 200 hex nuts, including key parameters like F (across flats), G (across corners) & H (thickness). The chart helps engineers, technicians & buyers to make sure they fit well & follow the needed standards for different projects. Perfect for use in product design, quality checks & installation planning.

| Nominal Size of D | Diameter of Body | Head Thickness | Flats Across | Corners Across | ||||

|---|---|---|---|---|---|---|---|---|

| D (Max) | D (Min) | H (Max) | H (Min) | F (Max) | F (Min) | C (Max) | C (Min) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.20 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.90 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Nickel 200 Heavy Hex Nut Dimensions Chart

This chart provides the standard dimensions for Heavy Hex Nuts made from Werkstoff Nr. 2.4066 (Nickel 200). It includes key measurements such as F (width across flats), G (width across corners) & H (nut thickness). These specifications are essential for ensuring a proper fit & reliable performance in high-temperature or corrosion resistant applications in order to help engineers, manufacturers & buyers select the right components for their projects.

| Nominal Size of D | Diameter of Body | Thickness of Head | Flats Across | Bolts Corners Across | ||||

|---|---|---|---|---|---|---|---|---|

| D (Maximum) | D (Minimum) | H (Maximum) | H (Minimum) | F (Maximum) | F (Minimum) | C (Maximum) | C (Minimum) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.20 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.90 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Nickel 200 Machine Screw Hex Nut Size & Dimension Chart

This chart provides detailed dimensions for Nickel 200 machine screw hex nuts, including the nominal size, major thread diameter, width across flats (F), width across corners (G) & nut thickness (H). These measurements help engineers, designers & buyers choose the correct nut size for precise assembly.

| Nominal Size | Basic Major Diameter of Thread | Width Across Flats (F) | Width Across Corners (G) | Thickness (H) | ||||

|---|---|---|---|---|---|---|---|---|

| Basic | Min | Max | Min | Max | Min | Max | ||

| 0 | 0.060 | 5/32 | 0.150 | 0.156 | 0.171 | 0.180 | 0.043 | 0.050 |

| 1 | 0.073 | 5/32 | 0.150 | 0.156 | 0.171 | 0.180 | 0.043 | 0.050 |

| 2 | 0.086 | 3/16 | 0.180 | 0.188 | 0.205 | 0.217 | 0.057 | 0.066 |

| 3 | 0.099 | 3/16 | 0.180 | 0.188 | 0.205 | 0.217 | 0.057 | 0.066 |

| 4 | 0.112 | 1/4 | 0.241 | 0.250 | 0.275 | 0.289 | 0.087 | 0.098 |

| 5 | 0.125 | 5/16 | 0.302 | 0.312 | 0.344 | 0.361 | 0.102 | 0.114 |

| 6 | 0.138 | 5/16 | 0.302 | 0.312 | 0.344 | 0.361 | 0.102 | 0.114 |

| 8 | 0.164 | 11/32 | 0.332 | 0.344 | 0.378 | 0.397 | 0.117 | 0.130 |

| 10 | 0.190 | 3/8 | 0.362 | 0.375 | 0.413 | 0.433 | 0.117 | 0.130 |

| 12 | 0.216 | 7/16 | 0.423 | 0.438 | 0.482 | 0.505 | 0.148 | 0.161 |

| 1/4 | 0.250 | 7/16 | 0.423 | 0.438 | 0.482 | 0.505 | 0.178 | 0.193 |

| 5/16 | 0.312 | 9/16 | 0.545 | 0.562 | 0.621 | 0.650 | 0.208 | 0.225 |

| 3/8 | 0.375 | 5/8 | 0.607 | 0.625 | 0.692 | 0.722 | 0.239 | 0.257 |

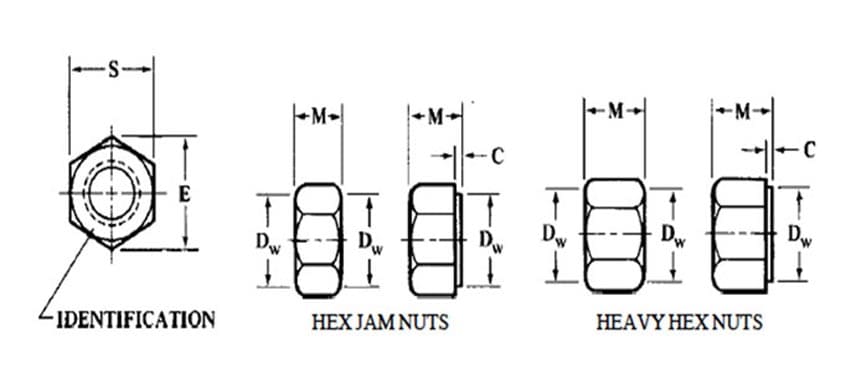

Nickel 200 Hex Jam Nut Dimensions Chart

The chart mentioned below shows that the standard dimensions for Nickel 200 hex jam nuts, including the nominal thread size, basic major diameter, width across flats (F), width across corners (G) & nut thickness (H). These measurements are essential for selecting the right nut size for compact or low-clearance applications.

| Nominal Size | Basic Major Diameter of Thread | F Width Across Flats | G Width Across Corners | H Thickness Hex Nuts | |||

|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | ||

| 1/4 | 0.2500 | 0.428 | 0.438 | 0.488 | 0.505 | 0.212 | 0.226 |

| 5/16 | 0.3125 | 0.489 | 0.500 | 0.557 | 0.577 | 0.258 | 0.273 |

| 3/8 | 0.3750 | 0.551 | 0.563 | 0.628 | 0.650 | 0.320 | 0.337 |

| 7/16 | 0.4375 | 0.675 | 0.688 | 0.768 | 0.794 | 0.365 | 0.385 |

| 1/2 | 0.5000 | 0.736 | 0.750 | 0.840 | 0.866 | 0.427 | 0.448 |

| 9/16 | 0.5625 | 0.861 | 0.875 | 0.982 | 1.010 | 0.473 | 0.496 |

| 5/8 | 0.6250 | 0.922 | 0.938 | 1.051 | 1.083 | 0.535 | 0.559 |

| 3/4 | 0.7500 | 1.088 | 1.125 | 1.240 | 1.299 | 0.617 | 0.665 |

| 7/8 | 0.8750 | 1.269 | 1.312 | 1.447 | 1.516 | 0.724 | 0.776 |

| 1 | 1.0000 | 1.450 | 1.500 | 1.653 | 1.732 | 0.831 | 0.887 |

| 1-1/8 | 1.1250 | 1.631 | 1.688 | 1.859 | 1.949 | 0.939 | 0.999 |

| 1-1/4 | 1.2500 | 1.812 | 1.875 | 2.066 | 2.165 | 1.030 | 1.094 |

| 1-3/8 | 1.3750 | 1.994 | 2.062 | 2.273 | 2.382 | 1.138 | 1.206 |

| 1-1/2 | 1.5000 | 2.175 | 2.250 | 2.480 | 2.598 | 1.245 | 1.317 |

| 1-5/8 | 1.6250 | 2.35 | 2.43 | 2.679 | 2.805 | 1.364 | 1.416 |

| 1-3/4 | 1.7500 | 2.538 | 2.625 | 2.893 | 3.031 | 1.460 | 1.540 |

| 1-7/8 | 1.8750 | 2.722 | 2.813 | 3.103 | 3.247 | 1.567 | 1.651 |

| 2 | 2.0000 | 2.900 | 3.0000 | 3.306 | 3.464 | 1.675 | 1.763 |

| 2-1/4 | 2.2500 | 3.263 | 3.375 | 3.719 | 3.897 | 1.890 | 1.986 |

| 2-1/2 | 2.500 | 3.625 | 3.750 | 4.133 | 4.330 | 2.105 | 2.209 |

| 2-3/4 | 2.7500 | 3.988 | 4.125 | 4.546 | 4.763 | 2.319 | 2.431 |

| 3 | 3.000 | 4.350 | 4.500 | 4.959 | 5.196 | 2.534 | 2.654 |

| 3-1/4 | 3.2500 | 4.713 | 4.875 | 5.373 | 5.629 | 2.749 | 2.877 |

| 3-1/2 | 3.500 | 5.075 | 5.250 | 5.786 | 6.062 | 2.964 | 3.100 |

| 3-3/4 | 3.7500 | 5.438 | 5.625 | 6.199 | 6.495 | 3.178 | 3.322 |

| 4 | 4.0000 | 5.800 | 6.000 | 6.612 | 6.928 | 3.393 | 3.545 |

Nickel 200 Hex Nut Tolerance Chart

Nickel 200 Hex Nuts are designed with tight tolerances to ensure a secure & consistent fit during assembly. Tolerance refers to the acceptable variation in the nut dimensions such as width across flats, thread diameter, & thickness which ensures compatibility with bolts & other fastening components. It will help to maintain accurate thread engagement, prevent loosening due to vibration to ensure a tight & leak-proof connection & allow for easy interchangeability between parts. To maintain these performance standards, Nickel 200 hex nuts are manufactured in accordance with international tolerance norms ISO 47591 for metric sizes & ANSI/ASME B18.2.2 for imperial sizes.

Both standards define the permissible dimensional variation in features like:

- Width Across Flats (F) — The distance between two parallel sides

- Width Across Corners (G) – the diagonal measurement across the nut

- Height (H) – the overall nut thickness

- Thread Pitch Diameter – how tightly or loosely the threads fit

For example:

A 1/2" Nickel 200 hex nut may have a width across flats tolerance of ±0.01 inch depending on its grade and class. For metric M12 nuts, the tolerance class may be specified as "6H" indicating medium fit commonly used for general-purpose mechanical applications.

Nickel 200 Hex Nuts Thickness Chart

The thickness of Nickel 200 Hex Nuts varies based on the nut size & the applicable standards, such as DIN (German) or ANSI/ASME (American) specifications. Thickness is a critical dimension that influences the mechanical strength of the nut, its load-bearing capacity & the amount of thread engagement during assembly. Nickel 200 hex nut thicknes is essential for ensuring reliable performance in these critical applications. These dimensions conform to international norms & are suitable for industrial applications.

Below is a reference chart that outlines the standard thickness ranges for commonly used metric sizes of Nickel 200 hex nuts:

| Nut Size (Metric) | Thickness (mm) |

|---|---|

| M6 | 5.0 – 5.5 |

| M8 | 6.5 – 7.0 |

| M10 | 8.0 – 8.4 |

| M12 | 10.0 – 10.8 |

| M16 | 13.0 – 14.8 |

Custom Thickness Options

Unifit Metalloys offers the flexibility to manufacture Nickel 200 hex nuts in customized thicknesses to meet unique project requirements. Whether you need more thickness for stronger threads or less thickness to fit in tight spaces to provide the right size for your needs. We can deliver customized solutions while maintaining dimensional accuracy and performance.

Nickel 200 Hex Nuts Temperature Resistance

Nickel 200 Hex Nuts are most popular for their excellent thermal stability & performance across extreme temperature ranges. It is used in cryogenic or high temperature applications to maintain their structural integrity, corrosion resistance & mechanical strength. The temperature operating range of Nickel 200 Hex Nuts is from 200°C to +600°C.

Nickel 200 hex nuts are designed to perform reliably in both low & high temperatures:

- At cryogenic temperatures (as low as –200°C), they retain ductility & toughness, making them ideal for low-temperature storage systems or liquid gas handling.

- At elevated temperatures (up to +600°C or 1112°F), they maintain mechanical strength and resist oxidation and corrosion, critical for high-heat industrial processes.

Nickel 200 Hex Nuts Price List

We offer a wide range of industrial Nickel 200 Hex Nuts that meet IS, BS, and DIN standards, available at competitive market prices in India. For the latest pricing or more information, please call +91 22 66518521 or send us an email.

Applications of Nickel 200 Hex Nuts

Nickel 200 Hex Nuts are known for their excellent corrosion resistance, high thermal stability & mechanical strength to be used for a wide range of demanding industrial applications. These hex nuts are widely used in environments that involve high temperatures, aggressive chemicals or cryogenic conditions. These types of nickel 200 fasteners are used in high-end applications requiring superior material properties.

Typical application areas include:

- Chemical and Petrochemical Industries

- Oil & Gas Projects

- Power Generation Plants

- Marine and Shipbuilding

- Fertilizer Plants and Process Industries

- Heavy Engineering and Construction

- Valves, Pumps & Pressure Vessels

- Railways and Transportation

- Steel Plants and Industrial Equipment

- Home and Sanitary Fittings (Special Applications)

Get a Quick Quote for Nickel 200 Hex Nuts

Looking for high-quality Nickel 200 Hex Nuts for your next project? Fill out the form below and our technical sales team will get in touch with you promptly with pricing, availability, and detailed specifications. Our team will review your request & get back to you promptly with a detailed quote and product information. We are here to help you find the right Nickel 200 Hex Nut solution to meet your needs.

Let’s make your next project a success. Start your request now!Leading Manufacturer, Supplier & Exporter of Nickel 200 Hex Nuts

Our Nickel 200 Hex Nuts are crafted for durability and reliable fastening in extreme environments. With superior resistance to acids, alkalis, and chloride-containing media, these nuts are widely used in industries such as petrochemical, power generation, and aerospace. We ensure precise dimensions and finish for maximum performance and safety.

Frequently Asked Questions About Nickel 200 Hex Nuts

What standards do your Nickel 200 Hex Nuts comply with?

Our Nickel 200 Hex Nuts conform to international standards such as IS, BS, DIN, ANSI/ASME B18.2.2 & ISO 4759-1, depending on the customer requirements.

Are test certificates provided with the fasteners?

Yes, we provide Mill Test Certificates (EN 10204 3.1 or 3.2) & upon request, third-party inspection reports to ensure traceability & quality compliance.

Can I request custom dimensions or thread types?

Yes, we provide custom manufacturing for non standard dimensions, thread pitches (UNC, UNF, Metric Fine) & special designs based on your project needs.

What is the delivery timeline for bulk orders?

For standard sizes, delivery within India usually takes 7–10 working days. Bulk or custom orders may take 2–4 weeks depending on the complexity and quantity.

Are Nickel 200 Hex Nuts suitable for high-temperature or corrosive environments?

Yes, Nickel 200 Hex Nuts are highly resistant to corrosion, acids, alkalis & perform well in cryogenic and high-temperature conditions ranging from –200°C to +600°C.

Do you offer surface coatings or finishing options?

Yes, we offer several finishing options including plain finish, passivation, zinc plating, and other coatings as per your requirement.

What is Nickel 200 used for?

Nickel 200 is mainly used in chemical processing equipment, electrical and electronic components, and food handling systems. It performs well in caustic environments and areas requiring high corrosion resistance. Its purity and good mechanical properties make it suitable for heat exchangers, fasteners, and welded structures.

What is the difference between Nickel 200 and 201?

Nickel 200 contains slightly more carbon, giving it better strength at normal temperatures. Nickel 201 has lower carbon, which prevents embrittlement and makes it more stable for high-temperature applications. In simple terms, Nickel 200 is stronger at room temperature, while Nickel 201 is better suited for elevated heat conditions.