Unifit Metalloys Inc is a trusted manufacturer & supplier of Nickel 200 Hex Bolts known for their high purity, strength & excellent resistance to corrosive environments. Manufactured using 99.6% pure nickel, our bolts are ideal for critical applications in many industries. We offer nickel 200 hex bolts and nickel 200 stud bolts in both standard & custom sizes, adhering to international standards like ASTM B160 or ASME SB160. These are non-magnetic bolts which give high thermal and electrical conductivity and are also reliable in various temperature ranges from -200°C to +600°C. Small batches to maintain or large batches to use in large-scale industries. We also guarantee super speed, low cost and superior quality. Our Nickel 200 fasteners are specifically designed to offer tight and sure fittings and quality services in the most rigorous settings.

Request QuoteTable of Contents

- What is Nickel 200 Hex Bolts?

- Why Choose Unifit Nickel 200 Hex Bolts?

- Nickel 200 Hex Bolt Equivalent Grade

- Nickel 200 Hex Bolt Specification

- Chemical Composition

- Mechanical Properties

- Hex Bolt Size Chart

- Dimensions Chart

- Torque Chart

- Heavy Hex Bolts Dimensions

- Structural Bolt Dimensions

- Weight Chart

- Hex Head Bolt Length Tolerances

- Fully Threaded Bolt Min Body / Max Grip Lengths

- Partially Threaded Bolt Min Body / Max Grip Lengths

- Request a Quick Quote

- Global Manufacturer & Exporter

- Frequently Asked Questions

What is Nickel 200 Hex Bolts?

Nickel 200 Hex Bolts are high-performance fasteners made from pure nickel (UNS N02200 / WNR 2.4066) known for their excellent mechanical strength, corrosion resistance & thermal conductivity. Designed with a six-sided head, these bolts are commonly tightened using a spanner or wrench offering secure & stable fastening in applications. Hex bolts are widely used across many industries due to their versatility & reliability. They are manufactured by using nickel 200 material to offer superior resistance to chemicals & oxidizing environments to be used for harsh industrial conditions. These bolts are available in multiple thread forms such as coarse & fine metric threads. They can be designed in various lengths & diameters to meet diverse application needs with surface finishes like nickel plating, black oxide etc to improve durability & protect against corrosion. These fasteners have flanged heads for larger load distribution, pre-applied locking agents for vibration resistance & sealing washers for leak prevention in fluid systems.

Nickel 200 Hex Bolts Chemical Composition

The chemical composition of Nickel 200 Hex Bolts includes a minimum of 99% nickel with controlled amounts of carbon, manganese, silicon, sulfur, copper, and iron. This pure nickel grade offers excellent corrosion resistance and mechanical stability in diverse industrial environments.

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Send Your Enquiry

Nickel 200 Hex Bolts Mechanical Properties

The Nickel 200 Hex Bolts mechanical properties include high tensile strength of 67,000 psi and excellent elongation of 45%, supported by a density of 8.9 g/cm 3 and a high melting point of 1446°C. These properties make Nickel 200 ideal for high-temperature and corrosion-prone applications.

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 200 | 8.9 g/cm³ | 1446°C (2635°F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45% |

Nickel 200 Hex Bolt Equivalent Grade

The Nickel 200 Hex Bolt has several equivalent grades across global standards, including WERKSTOFF NR. 2.4066, UNS N02200, JIS NW 2200, BS NA 11, GOST НП-2, AFNOR N-100M, and EN Ni 99.2. This ensures wide compatibility and material availability for international projects.

| Standard | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

Nickel 200 Hex Bolt Specification

The Nickel 200 Hex Bolts Specification covers ASTM B160 / ASME SB160 standards, available in lengths from 8mm to 100mm (3/8" to 4") and sizes M5 to M16 (1/4" to 5/8"), with custom dimensions supplied on request.

| Specifications | Length | Size |

|---|---|---|

| ASTM B160 / ASME SB160 | 8mm to 100mm | 3/8" to 4" | M5 to M16, (1/4" to 5/8") Custom Sizes |

Why Choose Unifit for Nickel 200 Hex Bolts?

Unifit is a leading Nickel 200 Hex Bolts manufacturer & supplier, trusted by industries worldwide for quality, precision & reliability. Let's understand the reasons why to select us for nickel 200 nuts needs:

- Quality Standrads: Unifit follows ISO certified manufacturing standards to ensure every Nickel 200 Hex Bolt meets the highest quality & performance benchmarks. Our bolts are tested for strength, durability & corrosion resistance.

- Customization Solutions: Whether it is a specific size, thread type or finish, Unifit offers custom manufacturing to match your exact project requirements. From M3 to M56 or 1/4” to 2”, we deliver precision-made fasteners tailored to your application.

- In-House Testing & Inspection: All bolts go through advanced testing procedures including mechanical, chemical & dimensional checks. We provide full material traceability with MTCs & third-party inspection reports on request.

- Competitive Pricing: Unifit combines in-house production, bulk sourcing & lean operations to offer affordable pricing without compromising on quality or standards.

Nickel 200 Hex Bolts Size Chart

At Unifit, we offer a comprehensive range of Nickel 200 Hex Bolts in both metric and imperial sizes to suit various industrial applications. Our bolts are manufactured to international standards (ASTM B160/B574, DIN, ISO, and ANSI), ensuring reliable strength, fit, and corrosion resistance.

| Diameter | Head Size |

|---|---|

| 1/4" | 7/16" |

| 5/16" | 1/2" |

| 3/8" | 9/16" |

| 7/16" | 5/8" |

| 1/2" | 3/4" |

| 9/16" | 13/16" |

| 5/8" | 15/16" |

| 3/4" | 1 1/8" |

| 7/8" | 1 5/16" |

| 1" | 1 1/2" |

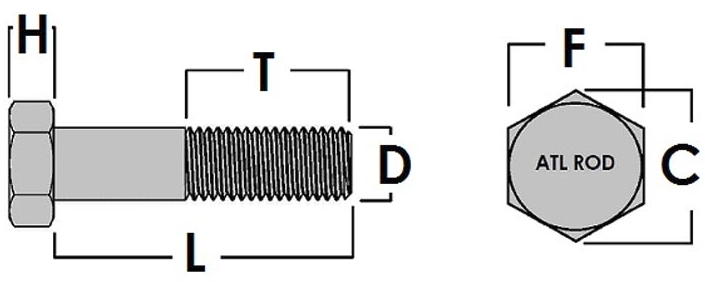

Nickel 200 Hex Bolts Dimensions Chart

Nickel 200 hex bolts are precision-engineered fasteners widely used in chemical processing, marine, and high-temperature applications. The following dimension chart provides the standard sizes, thread pitch, head dimensions, and length ranges available to help you select the right fastener for your project.

| Nominal Size | Threads per Inch |

Head Width | Head Height Basic Avg |

Minimum Threaded Length |

||||

|---|---|---|---|---|---|---|---|---|

| Fraction | Decimal | UNC | UNF | Across Flats |

Across Corners |

≤6" | >6" | |

| 1/4 | 0.2500 | 20 | 28 | 7/16 | 1/2 | 5/32 | 3/4 | 1 |

| 5/16 | 0.3125 | 18 | 24 | 1/2 | 9/16 | 13/64 | 7/8 | 1 1/8 |

| 3/8 | 0.3750 | 16 | 24 | 9/16 | 41/64 | 15/64 | 1 | 1 1/4 |

| 7/16 | 0.4375 | 14 | 20 | 5/8 | 45/64 | 9/32 | 1 1/8 | 1 3/8 |

| 1/2 | 0.5000 | 13 | 20 | 3/4 | 55/64 | 5/16 | 1 1/4 | 1 1/2 |

| 9/16 | 0.5625 | 12 | 18 | 13/16 | 59/64 | 23/64 | 1 3/8 | 1 5/8 |

| 5/8 | 0.6250 | 11 | 18 | 15/16 | 1 1/16 | 25/64 | 1 1/2 | 1 3/4 |

| 3/4 | 0.7500 | 10 | 16 | 1 1/8 | 1 9/32 | 15/32 | 1 3/4 | 2 |

| 7/8 | 0.8750 | 9 | 14 | 1 5/16 | 1 31/64 | 35/64 | 2 | 2 1/4 |

| 1 | 1.0000 | 8 | 12 | 1 1/2 | 1 45/64 | 39/64 | 2 1/4 | 2 1/2 |

| 1 1/8 | 1.1250 | 7 | 12 | 1 11/16 | 1 29/32 | 11/16 | 2 1/2 | 2 3/4 |

| 1 1/4 | 1.2500 | 7 | 12 | 1 7/8 | 2 7/64 | 25/32 | 2 3/4 | 3 |

| 1 3/8 | 1.3750 | 6 | 12 | 2 1/16 | 2 21/64 | 27/32 | 3 | 3 1/4 |

| 1 1/2 | 1.5000 | 6 | 12 | 2 1/4 | 2 17/32 | 1 5/16 | 3 1/4 | 3 1/2 |

Torque Chart of Nickel 200 Heavy Hex Bolts

The Torque Chart of Nickel 200 Heavy Hex Bolts shows recommended tightening values for lubricated threads, ensuring proper clamping force without damaging the fastener in high-temperature or corrosive environments. Unifit Fasteners provides expert support in selecting the correct torque and Nickel 200 Hex Bolts for your application.

| Bolt Size (Dia.) | Thread Pitch (mm) | Torque (Nm) | Torque (ft-lbs) |

|---|---|---|---|

| M6 | 1.0 | 10 – 12 | 7.4 – 8.9 |

| M8 | 1.25 | 25 – 30 | 18.4 – 22.1 |

| M10 | 1.5 | 50 – 60 | 36.9 – 44.3 |

| M12 | 1.75 | 85 – 100 | 62.7 – 73.8 |

| M16 | 2.0 | 210 – 240 | 154.9 – 177.0 |

| M20 | 2.5 | 410 – 460 | 302.3 – 339.2 |

| M24 | 3.0 | 710 – 780 | 523.7 – 575.5 |

| M30 | 3.5 | 1420 – 1570 | 1047.3 – 1157.5 |

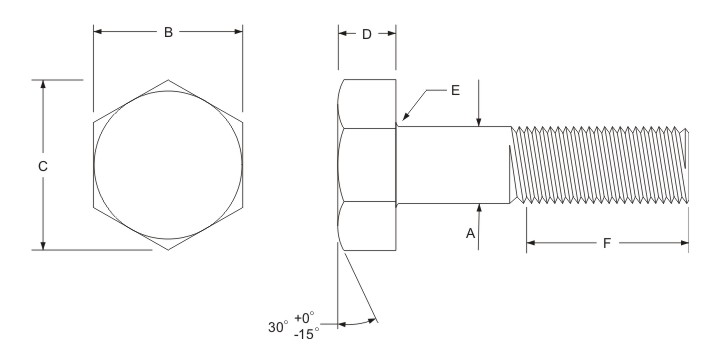

Nickel 200 Heavy Hex Bolts Dimensions Chart

Nickel 200 Heavy Hex Bolts are designed with a larger head & thicker body compared to standard hex bolts, offering enhanced strength & torque-bearing capacity.

Below is a general dimension chart for Nickel 200 Heavy Hex Bolts as per ASME B18.2.1 (inch series) and ISO standards (metric series):

| Nominal Size Of D | Diameter Of Body | Thickness Of Head | Flats Across | Bolts Corners Across | ||||

|---|---|---|---|---|---|---|---|---|

| D (Maximum) | D (Minimum) | H (Maximum) | H (Minimum) | F (Maximum) | F (Minimum) | C (Maximum) | C (Minimum) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Dimensions of Nickel Alloy 200 Heavy Hex Structural Bolt

The Dimensions of Nickel Alloy 200 Heavy Hex Structural Bolt ensure higher clamping strength and durability, featuring a larger head and thicker body for demanding structural and corrosive applications. These Nickel Alloy 200 Hex Structural Bolts are built for long-term performance.

| Bolt Size | A | B | C | Radius of Fillet (E) | Thread Length (F) | Transitional Thread Length | Runout of Bearing Surface FIM | |||

|---|---|---|---|---|---|---|---|---|---|---|

| max | min | min | max | min | max | min | max | |||

| 1/2″ | 0.515 | 0.482 | 7/8 | 0.969 | 5/16 | 0.031 | 0.009 | 1.00 | 0.19 | 0.016 |

| 5/8″ | 0.642 | 0.605 | 1-1/16 | 1.175 | 25/64 | 0.062 | 0.021 | 1.25 | 0.22 | 0.019 |

| 3/4″ | 0.768 | 0.729 | 1-1/4 | 1.383 | 15/32 | 0.062 | 0.021 | 1.38 | 0.25 | 0.022 |

| 7/8″ | 0.895 | 0.852 | 1-7/16 | 1.589 | 35/64 | 0.062 | 0.031 | 1.50 | 0.28 | 0.025 |

| 1″ | 1.022 | 0.976 | 1-5/8 | 1.796 | 39/64 | 0.093 | 0.062 | 1.75 | 0.31 | 0.028 |

| 1-1/8″ | 1.149 | 1.098 | 1-13/16 | 2.002 | 11/16 | 0.093 | 0.062 | 2.00 | 0.34 | 0.032 |

| 1-1/4″ | 1.277 | 1.223 | 2 | 2.209 | 25/32 | 0.093 | 0.062 | 2.00 | 0.38 | 0.035 |

| 1-3/8″ | 1.404 | 1.345 | 2-3/16 | 2.416 | 27/32 | 0.093 | 0.062 | 2.25 | 0.44 | 0.038 |

| 1-1/2″ | 1.531 | 1.470 | 2-3/8 | 2.622 | 15/16 | 0.093 | 0.062 | 2.25 | 0.44 | 0.041 |

Weight Chart Of Nickel Alloy 200 Hex Bolts

These hex bolts are known for their high corrosion resistance & excellent mechanical properties. Knowing the weight of hex bolts will help in transport planning, load calculations & structural design.

Below is a standard weight chart for full thread Nickel 200 hex bolts based on diameter & length using a material density of approx 8.89 g/cm³.

THREADS According to IS 1363/67

APPROX. WEIGHT IN KGS FOR 100 NOS

| LENGTH in mm | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 |

|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 0.448 | 0.743 | 1.590 | 3.211 | ||||||

| 20 | 0.598 | 0.812 | 4.892 | 1.711 | 3.411 | |||||

| 25 | 0.660 | 0.897 | 5.252 | 1.871 | 3.660 | 8.170 | ||||

| 30 | 0.737 | 1.010 | 5.574 | 2.070 | 3.912 | 10.707 | 9.690 | 18.657 | ||

| 35 | 0.804 | 1.120 | 5.974 | 2.271 | 4.223 | 11.416 | 10.000 | 19.608 | 16.026 | |

| 40 | 0.881 | 1.230 | 6.410 | 2.470 | 4.533 | 12.107 | 10.288 | 20.747 | 16.667 |

Hex Head Bolt Length Tolerances

Hex head bolt length tolerances ensure dimensional accuracy for secure fits and reliable performance in assemblies. For Nickel 200 Hex Bolts, these tolerances are standardized based on bolt diameter and length. These tolerances conform to ASTM, DIN, or ISO standards depending on the specification. Maintaining correct bolt length ensures consistent clamping force and thread engagement.

Hex Head Bolt Length Tolerances

| Nominal Length | Dia. 1/4″ to 3/8″ | Dia. 7/16″ & 1/2″ | Dia. 9/16″ to 3/4″ | Dia. 7/8″ & 1″ | Dia. 1-1/8″ to 1-1/2″ | Over 1-1/2″ Dia. |

|---|---|---|---|---|---|---|

| Up to & Incl. 1″ | -0.03 +0.02 | -0.03 +0.02 | -.003 +0.02 | — — | — — | — — |

| Over 1″ up to & incl. 2-1/2″ | -0.04 +0.02 | -0.06 +0.04 | -0.08 +0.06 | -0.10 +0.08 | -0.12 +0.12 | 0.18 +0.18 |

| Over 2-1/2″ up to & incl. 4″ | -0.06 +0.04 | -0.08 +0.06 | -0.10 +0.08 | -0.14 +0.10 | -0.16 +0.16 | -0.20 +0.22 |

| Over 4″ up to & incl. 6″ | -0.10 +0.06 | -0.10 +0.08 | -0.10 +0.10 | -0.16 +0.14 | -0.18 +0.18 | -0.22 +0.22 |

| Longer than 6″ | -0.18 +0.10 | -0.18 +0.12 | -0.18 +0.14 | -0.20 +0.16 | -0.22 +0.22 | -0.24 +0.24 |

Fully Threaded Minimum Body & Maximum Grip Gaging Lengths for Nickel 200 Hex Bolts

In fully threaded Nickel 200 Hex Bolts, the body refers to the unthreaded portion between the head and the start of threads — which is minimal or absent.

Minimum Body Length: Practically 0 mm (fully threaded)

Maximum Grip Gaging Length: Equal to nominal bolt length minus thread run-out

This configuration is ideal for short clamp lengths and when full thread engagement is required in tapped holes or with nuts.

| Nominal Diameter | LB Min | LG Max | All Threads Series ≤ | All Threads Length > | All Threads Length ≤ | Coarse Thread (UNC) | Fine Thread (UNF) | 8UN Thread |

|---|---|---|---|---|---|---|---|---|

| 1/4 | 0.043 | 0.500 | 0.075 | 0.500 | 1.125 | 0.125 | 0.089 | — |

| 3/16 | 0.045 | 0.625 | 0.083 | 0.625 | 1.250 | 0.139 | 0.104 | — |

| 3/8 | 0.048 | 0.750 | 0.094 | 0.750 | 1.375 | 0.156 | 0.104 | — |

| 7/16 | 0.052 | 0.875 | 0.107 | 0.875 | 1.625 | 0.179 | 0.125 | — |

| 1/2 | 0.053 | 1.000 | 0.115 | 1.000 | 1.750 | 0.192 | 0.125 | — |

| 9/16 | 0.075 | 1.125 | 0.125 | 1.125 | 2.000 | 0.208 | 0.139 | — |

| 5/8 | 0.078 | 1.250 | 0.136 | 1.250 | 2.125 | 0.227 | 0.139 | — |

| 3/4 | 0.081 | 1.500 | 0.150 | 1.500 | 2.500 | 0.250 | 0.156 | — |

| 7/8 | 0.105 | — | — | — | 2.750 | 0.278 | 0.179 | — |

| 1 | 0.140 | — | — | — | 3.000 | 0.312 | 0.208 | — |

| 1 1/8 | 0.146 | — | — | — | 3.500 | 0.357 | 0.208 | 0.312 |

| 1 1/4 | 0.146 | — | — | — | 3.750 | 0.357 | 0.208 | 0.312 |

| 1 3/8 | 0.154 | — | — | — | 4.250 | 0.417 | 0.208 | 0.312 |

| 1 1/2 | 0.154 | — | — | — | 4.500 | 0.417 | 0.208 | 0.312 |

| 1 3/4 | 0.166 | — | — | — | 5.125 | 0.500 | — | 0.312 |

| 2 | 0.173 | — | — | — | 5.750 | 0.556 | — | 0.312 |

| 2 1/4 | 0.173 | — | — | — | 6.500 | 0.556 | — | 0.312 |

| 2 1/2 | 0.183 | — | — | — | 7.125 | 0.625 | — | 0.312 |

| 2 3/4 | 0.183 | — | — | — | 7.625 | 0.625 | — | 0.312 |

| 3 | 0.183 | — | — | — | 8.125 | 0.625 | — | 0.312 |

Partially Threaded Minimum Body & Maximum Grip Gaging Lengths

Partially threaded Nickel 200 Hex Bolts have a defined unthreaded body portion, offering greater shear strength for heavy-load or structural applications.

Minimum Body Length: Defined by standards (e.g., ISO 4014 or ANSI B18.2.1)

Maximum Grip Gaging Length: From the bearing surface of the head to the end of the unthreaded shank

These bolts handle both tensile and shear loads, making them suitable for flanged, structural, and pressure vessel assemblies.

| Length | Nominal Diameter E, Minimum Body Length (LB) / Maximum Grip Gaging Length (LG) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 7/8 | 1 | |

| 1 1/4 | 0.25 / 0.50 | Full Thread | Full Thread | Full Thread | Full Thread | Full Thread | Full Thread | Full Thread |

| 1 3/8 | 0.38 / 0.63 | 0.22 / 0.50 | Full Thread | Full Thread | Full Thread | Full Thread | Full Thread | Full Thread |

| 1 1/2 | 0.50 / 0.75 | 0.35 / 0.62 | 0.19 / 0.50 | Full Thread | Full Thread | Full Thread | Full Thread | Full Thread |

| 1 5/8 | 0.62 / 0.88 | 0.47 / 0.75 | 0.31 / 0.62 | Full Thread | Full Thread | Full Thread | Full Thread | Full Thread |

| 1 3/4 | 0.75 / 1.00 | 0.60 / 0.88 | 0.44 / 0.75 | Full Thread | Full Thread | Full Thread | Full Thread | Full Thread |

| 1 7/8 | 0.88 / 1.12 | 0.72 / 1.00 | 0.56 / 0.88 | 0.24 / 0.63 | Full Thread | Full Thread | Full Thread | Full Thread |

| 2 | 1.00 / 1.25 | 0.85 / 1.12 | 0.69 / 1.00 | 0.38 / 0.75 | Full Thread | Full Thread | Full Thread | Full Thread |

| 2 1/8 | 1.12 / 1.38 | 0.97 / 1.25 | 0.81 / 1.12 | 0.49 / 0.88 | Full Thread | Full Thread | Full Thread | Full Thread |

| 2 1/4 | 1.25 / 1.50 | 1.10 / 1.38 | 0.94 / 1.25 | 0.62 / 1.00 | 0.30 / 0.75 | Full Thread | Full Thread | Full Thread |

| 2 3/8 | 1.38 / 1.62 | 1.22 / 1.50 | 1.06 / 1.38 | 0.74 / 1.12 | 0.42 / 0.88 | Full Thread | Full Thread | Full Thread |

| 2 1/2 | 1.50 / 1.75 | 1.35 / 1.62 | 1.19 / 1.50 | 0.86 / 1.25 | 0.55 / 1.00 | Full Thread | Full Thread | Full Thread |

| 2 5/8 | 1.62 / 1.88 | 1.47 / 1.75 | 1.31 / 1.62 | 0.99 / 1.38 | 0.67 / 1.12 | 0.38 / 0.88 | Full Thread | Full Thread |

| 2 3/4 | 1.75 / 2.00 | 1.60 / 1.88 | 1.44 / 1.75 | 1.12 / 1.50 | 0.80 / 1.25 | 0.50 / 1.00 | Full Thread | Full Thread |

| 2 7/8 | 1.88 / 2.12 | 1.72 / 2.00 | 1.56 / 1.88 | 1.24 / 1.62 | 0.92 / 1.38 | 0.62 / 1.12 | 0.32 / 0.88 | Full Thread |

| 3 | 2.00 / 2.52 | 1.85 / 2.12 | 1.69 / 2.00 | 1.36 / 1.75 | 1.05 / 1.50 | 0.75 / 1.25 | 0.44 / 1.00 | Full Thread |

| 3 1/4 | 2.25 / 2.50 | 2.10 / 2.38 | 1.94 / 2.25 | 1.62 / 2.00 | 1.30 / 1.75 | 1.00 / 1.50 | 0.69 / 1.25 | 0.38 / 1.00 |

| 3 1/2 | 2.50 / 2.75 | 2.35 / 2.62 | 2.19 / 2.50 | 1.86 / 2.25 | 1.55 / 2.00 | 1.25 / 1.75 | 0.94 / 1.50 | 0.62 / 1.25 |

| 3 3/4 | 2.75 / 3.00 | 2.60 / 2.88 | 2.44 / 2.75 | 2.12 / 2.50 | 1.80 / 2.25 | 1.50 / 2.00 | 1.19 / 1.75 | 0.88 / 1.50 |

| 4 | 3.00 / 3.25 | 2.85 / 3.12 | 2.69 / 3.00 | 2.36 / 2.75 | 2.05 / 2.50 | 1.75 / 2.25 | 1.44 / 2.00 | 1.12 / 1.75 |

| 4 1/4 | 3.25 / 3.50 | 3.10 / 3.38 | 2.94 / 3.25 | 2.62 / 3.00 | 2.30 / 2.75 | 2.00 / 2.50 | 1.69 / 2.25 | 1.38 / 2.00 |

| 4 1/2 | 3.50 / 3.75 | 3.35 / 3.62 | 3.19 / 3.50 | 2.86 / 3.25 | 2.55 / 3.00 | 2.25 / 2.75 | 1.94 / 2.50 | 1.62 / 2.25 |

| 4 3/4 | 3.75 / 4.00 | 3.60 / 3.88 | 3.44 / 3.75 | 3.12 / 3.50 | 2.80 / 3.25 | 2.50 / 3.00 | 2.19 / 2.75 | 1.88 / 2.50 |

| 5 | 4.00 / 4.25 | 3.85 / 4.12 | 3.69 / 4.00 | 3.36 / 3.75 | 3.05 / 3.50 | 2.75 / 3.25 | 2.44 / 3.00 | 2.12 / 2.75 |

| 5 1/4 | 4.25 / 4.50 | 4.10 / 4.38 | 3.94 / 4.25 | 3.62 / 4.00 | 3.30 / 3.75 | 3.00 / 3.50 | 2.69 / 3.25 | 2.38 / 3.00 |

| 5 1/2 | 4.50 / 4.75 | 4.35 / 4.62 | 4.19 / 4.50 | 3.87 / 4.25 | 3.55 / 4.00 | 3.25 / 3.75 | 2.94 / 3.50 | 2.62 / 3.25 |

| 5 3/4 | 4.75 / 5.00 | 4.60 / 4.88 | 4.44 / 4.75 | 4.12 / 4.50 | 4.25 / 3.80 | 4.00 / 3.50 | 3.75 / 3.19 | 3.50 / 2.88 |

| 6 | 5.00 / 5.25 | 4.85 / 5.12 | 4.69 / 5.00 | 4.36 / 4.75 | 4.05 / 4.50 | 3.75 / 4.25 | 3.44 / 4.00 | 3.12 / 3.75 |

| 6 1/4 | 5.00 / 5.25 | 4.85 / 5.12 | 4.69 / 5.00 | 4.36 / 4.75 | 4.05 / 4.50 | 3.75 / 4.25 | 3.44 / 4.00 | 3.12 / 3.75 |

| 6 1/2 | 5.25 / 5.50 | 5.10 / 5.38 | 4.94 / 5.25 | 4.62 / 5.00 | 4.30 / 4.75 | 4.00 / 4.50 | 3.69 / 4.25 | 3.38 / 4.00 |

| 6 3/4 | 5.50 / 5.75 | 5.35 / 5.62 | 5.19 / 5.50 | 4.86 / 5.25 | 4.55 / 5.00 | 4.25 / 4.75 | 3.94 / 4.50 | 3.63 / 4.25 |

| 7 | 5.75 / 6.00 | 5.60 / 5.88 | 5.44 / 5.75 | 5.12 / 5.50 | 4.80 / 5.25 | 4.50 / 5.00 | 4.19 / 4.75 | 3.88 / 4.50 |

| 7 1/4 | 6.00 / 6.25 | 5.85 / 6.12 | 5.69 / 6.00 | 5.36 / 5.75 | 5.05 / 5.50 | 4.75 / 5.25 | 4.44 / 5.00 | 4.12 / 4.75 |

| 7 1/2 | 6.25 / 6.50 | 6.10 / 6.38 | 5.94 / 6.25 | 5.62 / 6.00 | 5.30 / 5.75 | 5.00 / 5.50 | 4.69 / 5.25 | 4.38 / 5.00 |

| 7 3/4 | 6.50 / 6.75 | 6.35 / 6.62 | 6.19 / 6.50 | 5.87 / 6.25 | 5.55 / 6.00 | 5.25 / 5.75 | 4.94 / 5.50 | 4.52 / 5.25 |

| 8 | 6.75 / 7.00 | 6.60 / 6.88 | 6.44 / 6.75 | 6.12 / 6.50 | 5.80 / 6.25 | 5.50 / 6.00 | 5.19 / 5.75 | 4.88 / 5.50 |

| 8 1/4 | 7.00 / 7.25 | 6.85 / 7.12 | 6.69 / 7.00 | 6.36 / 6.75 | 6.05 / 6.50 | 5.75 / 6.25 | 5.44 / 6.00 | 5.12 / 5.75 |

| 8 1/2 | 7.25 / 7.50 | 7.10 / 7.38 | 6.94 / 7.25 | 6.62 / 7.00 | 6.30 / 6.75 | 6.00 / 6.50 | 5.69 / 6.25 | 5.38 / 6.00 |

| 8 3/4 | 7.50 / 7.75 | 7.35 / 7.62 | 7.19 / 7.50 | 6.86 / 7.25 | 6.55 / 7.00 | 6.25 / 6.75 | 5.94 / 6.50 | 5.62 / 6.25 |

| 9 | 7.75 / 8.00 | 7.60 / 7.88 | 7.44 / 7.75 | 7.12 / 7.50 | 6.80 / 7.25 | 6.50 / 7.00 | 6.19 / 6.75 | 5.88 / 6.50 |

| 9 1/4 | 8.00 / 8.25 | 7.85 / 8.12 | 7.69 / 8.00 | 7.36 / 7.75 | 7.05 / 7.50 | 6.75 / 7.25 | 6.44 / 7.00 | 6.12 / 6.75 |

| 9 1/2 | 8.25 / 8.50 | 8.10 / 8.38 | 7.94 / 8.25 | 7.62 / 8.00 | 7.30 / 7.75 | 7.00 / 7.50 | 6.89 / 7.25 | 6.38 / 7.00 |

| 9 3/4 | 8.50 / 8.75 | 8.35 / 8.62 | 8.19 / 8.50 | 7.86 / 8.25 | 7.55 / 8.00 | 7.25 / 7.75 | 6.94 / 7.50 | 6.62 / 7.25 |

| 10 | 8.75 / 9.00 | 8.60 / 8.88 | 8.44 / 8.75 | 8.12 / 8.50 | 7.80 / 8.25 | 7.50 / 8.00 | 7.19 / 7.75 | 6.88 / 7.50 |

| 11 | 9.75 / 10.00 | 9.60 / 9.88 | 9.44 / 9.75 | 9.12 / 9.50 | 8.80 / 9.25 | 8.50 / 9.00 | 8.19 / 8.75 | 7.88 / 8.50 |

| 12 | 10.75 / 11.00 | 10.60 / 10.88 | 10.44 / 10.75 | 10.12 / 10.50 | 9.80 / 10.25 | 9.50 / 10.00 | 9.19 / 9.75 | 8.88 / 9.50 |

Get a Quick Quote for Nickel 200 Hex Bolts

Looking for corrosion-resistant fastening for your critical applications? Submit your inquiry for Nickel 200 Hex Bolts by filling out the form below. Include details such as size, thread type, quantity, and performance requirements.

Whether you're sourcing for high-temperature, chemical, or marine environments, our experts will provide a fast and accurate quote tailored to your project. We offer precision-made hex bolts that deliver strength and reliability under pressure.

Let us support your next build with trusted Nickel 200 solutions—get started now!

Leading Exporter, Manufacturer & Supplier of Nickel 200 Hex Bolts

We specialize in manufacturing and supplying top-grade Nickel 200 Hex Bolts known for their high strength, excellent thermal conductivity, and outstanding corrosion resistance. Ideal for chemical processing, marine, and high-temperature applications, our hex bolts are available in various sizes and specifications to meet global standards and project requirements.

Nickel 200 Hex Bolt, Alloy UNS N02200 Hexagon Bolts, Nickel 200 Heavy Hex Bolts Supplier, Ni 2.4066 Hex Bolt, Nickel 201 Half Threaded Hex Bolts, Nickel N02201 Hex Bolt, Nickel 201 Hex Head Bolt Manufacturer in India.

Nickel Alloy 200 Hex Flange Bolt, Nickel 201 Hex Machine Bolts, Nickel 200 Hexagonal Head Bolt, Ni Alloy 2.4068 Hex Bolts, Nickel Alloy 201 Full Threaded Hex Bolts, Nickel 200 Hexagonal Bolt Supplier in Mumbai, India.

Frequently Asked Questions About Nickel 200 Hex Bolts

What standards apply to Nickel 200 hex bolts?

These standards ensure precise dimensions, material integrity, and mechanical strength. Nickel 200 hex bolts typically conform to international standards such as:

- ASTM B160 – For Nickel 200 bars and rods (used in bolt production)

- ASME B18.2.1 / B18.2.2 – For dimensions of bolts and hex nuts

- DIN 933 / ISO 4017 – For fully threaded hex bolts

- ASTM F2281 – For fastener mechanical properties

What is the thread pitch of a hex bolt and why is it important?

Thread pitch is the distance between threads (in mm for metric bolts). Use a thread pitch gauge to identify pitch accurately.

Example: M10 × 1.5 means a 10 mm diameter bolt with 1.5 mm pitch.

Why it matters:

- Affects load distribution and fastening precision

- Must match the nut or tapped hole to ensure proper engagement

What is the difference between full thread and partial thread hex bolts?

Full Thread Bolts: Threaded along the entire shank. Ideal for clamping and holding materials of varying thicknesses.

Partial Thread Bolts: Threading stops before the head, leaving a smooth shank. Offers higher shear strength in the unthreaded section.

The choice depends on structural requirements and material stress distribution.

How to determine the right hex bolt size for an application?

Always refer to engineering drawings or consult a torque/load chart for critical applications. To choose the correct bolt size, consider:

- Load requirements (shear/tensile strength)

- Material compatibility (e.g., corrosion resistance in chemical environments)

- Hole size and thickness of the materials being fastened

- Thread type and pitch