Unifit Fastener is a trusted manufacturer & exporter of high quality nickel alloy fasteners specializing in Nickel 200 stud bolts. These fasteners are designed for high-performance applications to offer excellent mechanical properties & corrosion resistance even at elevated temperatures—up to 650°F.

Our Nickel 200 Stud Bolts (UNS N02200) are known for their purity, strength & formability to be used for chemical processing & marine industries. With excellent resistance to acids, alkalis & neutral salts, these stud bolts ensure long term performance in harsh conditions.

These nickel alloy 200 fasteners also maintain their two-phase microstructure even when diluted with austenite-forming elements like nickel, providing superior weld integrity & resistance to cracking. They exhibit excellent ductility, high toughness & superior resistance to corrosion and embrittlement at high temperatures.Nickel UNS N02200 Stud Bolts shall undergo mechanical tests such as transverse or longitudinal tension test and flattening test, where grain size determination and weld decay tests shall be performed.

Request QuoteWhat is Nickel 200 Stud Bolts?

Nickel 200 stud bolts are high-performance fasteners made from nickel material. Known for their excellent corrosion resistance especially in reducing & alkaline environments, these bolts are ideal for harsh industrial conditions involving acids, chemicals & seawater.

Nickel 200 stud bolts are commonly used in the chemical processing, marine, power generation & petrochemical industries. They offer superior mechanical strength, high ductility & thermal or electrical conductivity. These stud bolts are also non-magnetic & maintain strength at high & sub-zero temperatures. Due to their design, stud bolts are used to connect flanges, valves & high pressure piping systems providing a reliable & removable fastening solution. Nickel 200 stud bolts can withstand high pressure & temperature making them suitable for demanding applications like acid production, reactors & heat exchangers.

Send Your Enquiry

Specification of Nickel 200 Stud Bolts

Nickel 200 Stud Bolts are made from nickel (UNS N02200) mateial known for excellent mechanical properties & superior resistance to corrosive environments.

Below is a detailed specification table for Nickel 200 Stud Bolts:

| Specification | Details |

|---|---|

| Specifications | ASTM B160 / ASME SB160 |

| Length | 3mm to 200mm |

| Size | M02 to M33, Custom Sizes |

Types of Nickel 200 Stud Bolts

Nickel 200 Stud Bolts are available in a variety of types including continuous, partial, threaded & reduced to meet the specific requirements of different applications. These types differ in threading, length & end configurations offering flexibility for use in piping, pressure vessels, heat exchangers & structural components. Each type of Nickel 200 stud bolt is selected based on the mechanical load, temperature exposure, corrosion resistance needs, and the assembly design.

- Nickel Alloy 200 Studs

- Nickel 200 Threaded Stud Bolts

- Nickel 200 Threaded Studs

- Nickel 200 Continuous Thread Stud Bolt

- Nickel 200 Partial Threaded Stud Bolt

- Nickel 200 Reduced Shank Stud Bolt

- Nickel Alloy 200 Heavy Stud Bolt

- Nickel 200 Industrial Stud

- Nickel 200 Flush Head Studs

- Nickel 200 Threaded Rods

- Ni 200 Double Ended Threaded Stud

- Ni 200 Single Ended Threaded Stud

- Nickel 200 All Threaded Stud Bolts

- Nickel 200 Metric Thread Stud Bolt

Why Choose Unifit for Nickel 200 Stud Bolts?

Unifit Fasteners is a trusted name in the industry, offering precision-engineered Nickel 200 Stud Bolts designed for demanding applications. We stand out for:

- Quality Testing: Unifit Metalloys ensures every batch of Nickel 200 Stud Bolts is rigorously tested for hardness, tensile strength, chemical composition, and corrosion resistance. All products come with inspection and third-party certification as required.

- Customized Solution: We manufacture stud bolts in customized sizes, lengths, threads, and coatings to meet your specific industrial requirements with precise tolerances.

- Competitive Pricing: Our Nickel 200 Stud Bolts are competitively priced without compromising quality. We ensure cost-effective solutions backed by quick delivery timelines.

Nickel 200 Stud Bolts Size Chart

Nickel 200 Stud Bolts come in a variety of sizes to meet diverse application needs in the chemical, marine & power industries. These bolts are commonly manufactured as per ASTM B160 standards and are available in both metric and imperial sizes.

Below is a standard size chart for Nickel 200 Stud Bolts:

| Class 150 Flanges ASME B16.5 (Stud bolt sizes) | Length of Stud Bolts | |||||||

|---|---|---|---|---|---|---|---|---|

| NPS | Outside Diameter of Flange | The diameter of Bolt Circle | The diameter of Bolt Holes | Number of Bolts | Diameter of Bolts | Raised Face 0.06 in |

Ring Joint | |

| 1/2 | 3 1/2 | 2 3/8 | 5/8 | 4 | 1/2 | 2 1/4 | – | |

| 3/4 | 3 7/8 | 2 3/4 | 5/8 | 4 | 1/2 | 2 1/2 | – | |

| 1 | 4 1/4 | 3 1/8 | 5/8 | 4 | 1/2 | 2 1/2 | 3 | |

| 1 1/4 | 4 5/8 | 3 1/2 | 5/8 | 4 | 1/2 | 2 3/4 | 3 1/4 | |

| 1 1/2 | 5 | 3 7/8 | 5/8 | 4 | 1/2 | 2 3/4 | 3 1/4 | |

| 2 | 6 | 4 3/4 | 3/4 | 4 | 5/8 | 3 1/4 | 3 3/4 | |

| 2 1/2 | 7 | 5 1/2 | 3/4 | 4 | 5/8 | 3 1/2 | 4 | |

| 3 | 7 1/2 | 6 | 3/4 | 4 | 5/8 | 3 1/2 | 4 | |

| 3 1/2 | 8 1/2 | 7 | 3/4 | 8 | 5/8 | 3 1/2 | 4 | |

| 4 | 9 | 7 1/2 | 3/4 | 8 | 5/8 | 3 1/2 | 4 | |

| 5 | 10 | 8 1/2 | 7/8 | 8 | 3/4 | 3 3/4 | 4 1/4 | |

| 6 | 11 | 9 1/2 | 7/8 | 8 | 3/4 | 4 | 4 1/2 | |

| 8 | 13 1/2 | 11 3/4 | 7/8 | 8 | 3/4 | 4 1/4 | 4 3/4 | |

| 10 | 16 | 14 3/4 | 1 | 12 | 7/8 | 4 1/2 | 5 | |

| 12 | 19 | 17 | 1 | 12 | 7/8 | 4 3/4 | 5 1/4 | |

| 14 | 21 | 18 3/4 | 1 1/8 | 12 | 1 | 5 1/4 | 5 3/4 | |

| 16 | 23 1/2 | 21 1/4 | 1 1/8 | 16 | 1 | 5 1/4 | 5 3/4 | |

| 18 | 25 | 22 3/4 | 1 1/4 | 16 | 1 1/8 | 5 3/4 | 6 1/4 | |

| 20 | 27 1/2 | 25 | 1 1/4 | 20 | 1 1/8 | 6 1/4 | 6 3/4 | |

| 24 | 32 | 29 1/2 | 1 1/4 | 20 | 1 1/4 | 6 3/4 | 7 1/4 | |

| Class 300 Flanges ASME B16.5 | Length of Stud Bolts | |||||||

| NPS | Outside Diameter of Flange | The diameter of Bolt Circle | The diameter of Bolt Holes | Number of Bolts | Diameter of Bolts | Raised Face 0.06 in |

Ring Joint | |

| 1/2 | 3 3/4 | 2 5/8 | 5/8 | 4 | 1/2 | 2 1/2 | 3 | |

| 3/4 | 4 5/8 | 3 1/4 | 3/4 | 4 | 5/8 | 3 | 3 1/2 | |

| 1 | 4 7/8 | 3 1/2 | 3/4 | 4 | 5/8 | 3 | 3 1/2 | |

| 1 1/4 | 5 1/4 | 3 7/8 | 3/4 | 4 | 5/8 | 3 1/4 | 3 3/4 | |

| 1 1/2 | 6 1/8 | 4 1/2 | 7/8 | 4 | 3/4 | 3 1/2 | 4 | |

| 2 | 6 1/2 | 5 | 3/4 | 8 | 5/8 | 3 1/2 | 4 | |

| 2 1/2 | 7 1/2 | 5 7/8 | 7/8 | 8 | 3/4 | 4 | 4 1/2 | |

| 3 | 8 1/4 | 6 5/8 | 7/8 | 8 | 3/4 | 4 1/4 | 4 3/4 | |

| 3 1/2 | 9 | 7 1/4 | 7/8 | 8 | 3/4 | 4 1/4 | 5 | |

| 4 | 10 | 7 7/8 | 7/8 | 8 | 3/4 | 4 1/2 | 5 | |

| 5 | 11 | 9 1/4 | 7/8 | 8 | 3/4 | 4 3/4 | 5 1/4 | |

| 6 | 12 1/2 | 10 5/8 | 7/8 | 12 | 3/4 | 4 3/4 | 5 1/2 | |

| 8 | 15 | 13 | 1 | 12 | 7/8 | 5 1/2 | 6 | |

| 10 | 17 1/2 | 15 1/4 | 1 1/8 | 16 | 1 | 6 1/4 | 6 3/4 | |

| 12 | 20 1/2 | 17 3/4 | 1 1/4 | 16 | 1 1/8 | 6 3/4 | 7 1/4 | |

| 14 | 23 | 20 1/4 | 1 1/4 | 20 | 1 1/8 | 7 | 7 1/2 | |

| 16 | 25 1/2 | 22 1/2 | 1 3/8 | 20 | 1 1/4 | 7 1/2 | 8 | |

| 18 | 28 | 24 3/4 | 1 3/8 | 24 | 1 1/4 | 7 3/4 | 8 1/4 | |

| 20 | 30 1/2 | 27 | 1 3/8 | 24 | 1 1/4 | 8 | 8 3/4 | |

| 24 | 36 | 32 | 1 5/8 | 24 | 1 1/2 | 9 | 10 | |

Weight Chart of Nickel 200 Stud Bolts

The weight of Nickel 200 Stud Bolts varies based on diameter, length & threading. Accurate weight estimation is essential for handling, logistics & structural load calculations in industrial applications such as piping, refineries, and marine environments.

Below is a sample Nickel 200 Stud Bolt Weight Chart (approximate weights in kilograms):

| Weight Imperial | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STUD BOLT LENGTH (in inches) | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1.3/8 | 1 1/2 | 1.5/8 | 1.3/4 | 1 7/8 | |

| 2.1/2 | 10.8 | ||||||||||||

| 2.3/4 | 11.6 | 19.8 | |||||||||||

| 3.1/4 | 12.4 | 21 | 32.4 | ||||||||||

| 3.1/2 | 13.2 | 22.2 | 34.3 | 50 | |||||||||

| 4 | 14 | 23.4 | 36.2 | 52.6 | 71.8 | ||||||||

| 4.1/2 | 14.8 | 24.6 | 38.1 | 55.2 | 75.2 | 102 | |||||||

| 4.3/4 | 15.6 | 25.8 | 40 | 57.8 | 78.6 | 106 | 137 | ||||||

| 5 | 16.4 | 27 | 41.9 | 60.4 | 82 | 111 | 142 | 179 | |||||

| 5.1/2 | 17.2 | 28.2 | 43.8 | 63 | 85.4 | 115 | 147 | 186 | 234 | ||||

| 6 | 18 | 29.4 | 45.7 | 65.6 | 88.8 | 119 | 153 | 193 | 242 | 289 | |||

| 6.1/4 | 18.8 | 30.6 | 47.6 | 68.2 | 92.2 | 123 | 158 | 200 | 250 | 298 | 263 | ||

| 6.1/2 | 19.6 | 32.3 | 49.5 | 70.8 | 95.6 | 128 | 164 | 206 | 258 | 308 | 374 | 437 | |

| 7 | 20.4 | 33.5 | 50.8 | 73.4 | 99 | 132 | 169 | 213 | 266 | 317 | 385 | 449 | |

| 7.1/2 | 21.2 | 34.8 | 52.7 | 75.5 | 103 | 136 | 174 | 220 | 275 | 326 | 396 | 462 | |

| 8 | 22 | 36.1 | 54.5 | 78 | 106 | 141 | 180 | 226 | 283 | 336 | 407 | 475 | |

| 8.1/4 | 37.3 | 56.3 | 80.5 | 108 | 145 | 185 | 233 | 291 | 345 | 418 | 488 | ||

| 8.3/4 | 38.6 | 58.1 | 83.1 | 112 | 149 | 191 | 240 | 299 | 354 | 429 | 500 | ||

| 9 | 39.8 | 60 | 85.6 | 115 | 153 | 196 | 246 | 307 | 364 | 440 | 513 | ||

| 9.1/2 | 41.1 | 61.8 | 88.2 | 118 | 158 | 201 | 253 | 316 | 373 | 451 | 526 | ||

| 10 | 63.7 | 90.7 | 122 | 162 | 206 | 260 | 324 | 382 | 463 | 538 | |||

| 10/1.4 | 93.3 | 125 | 166 | 212 | 267 | 332 | 391 | 474 | 551 | ||||

| 1.0.1/2 | 128 | 171 | 217 | 273 | 340 | 401 | 485 | 564 | |||||

| 11 | 132 | 175 | 223 | 279 | 345 | 410 | 496 | 576 | |||||

| 11.1/2 | 135 | 179 | 228 | 285 | 350 | 419 | 507 | 589 | |||||

| 12 | 138 | 184 | 233 | 292 | 358 | 429 | 518 | 602 | |||||

| Weight Of Metric Studs Bolt | |||||||||||||

| STUD BOLT LENGTH (in mm) | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 |

| 60 | 5,6 | 8,1 | 12 | 15,6 | |||||||||

| 70 | 6,1 | 8,9 | 13 | 16,9 | 23,7 | ||||||||

| 80 | 6,6 | 9,6 | 14 | 18,2 | 25,4 | 32,5 | |||||||

| 90 | 7,1 | 10,3 | 15 | 19,6 | 27,1 | 34,5 | 45,5 | ||||||

| 100 | 7,6 | 11 | 16 | 21 | 28,8 | 36,7 | 47,2 | 54,2 | |||||

| 110 | 8,1 | 11,7 | 17 | 22,2 | 30,4 | 38,7 | 48,3 | 58,2 | 80 | ||||

| 120 | 8,6 | 12,4 | 18 | 23,6 | 32,1 | 40,7 | 50,9 | 60,2 | 84,7 | 107 | |||

| 130 | 9,1 | 13,2 | 19 | 24,9 | 33,7 | 42,8 | 53,4 | 63,2 | 88,6 | 111 | 141 | ||

| 140 | 9,6 | 14,2 | 20 | 26,2 | 35,4 | 44,9 | 55,9 | 66,2 | 92,4 | 116 | 147 | 185 | |

| 150 | 10,1 | 14,9 | 20,8 | 27,5 | 36,9 | 46,9 | 58,5 | 69,2 | 96,3 | 121 | 153 | 192 | 237 |

| 160 | 10,6 | 15,6 | 21,8 | 29,1 | 38,6 | 49 | 61 | 72,2 | 100,1 | 126 | 159 | 199 | 245 |

| 170 | 16,4 | 22,8 | 30,4 | 40,2 | 51,1 | 63,5 | 75,2 | 104 | 130 | 165 | 206 | 253 | |

| 180 | 23,8 | 31,8 | 41,9 | 52,3 | 66,1 | 78,1 | 108 | 135 | 171 | 213 | 261 | ||

| 190 | 33,1 | 43,5 | 54,4 | 68,4 | 81,1 | 112 | 140 | 176 | 219 | 269 | |||

| 200 | 34,5 | 45,2 | 56,2 | 71 | 84 | 116 | 144 | 182 | 226 | 278 | |||

| 210 | 35,8 | 46,8 | 58,5 | 73,5 | 88,4 | 120 | 149 | 188 | 233 | 286 | |||

| 220 | 37,1 | 48,4 | 60,6 | 76,1 | 91,4 | 124 | 154 | 194 | 240 | 294 | |||

| 230 | 38,5 | 50,1 | 62,6 | 78,6 | 94,4 | 127 | 159 | 201 | 247 | 302 | |||

| 240 | 39,8 | 51,7 | 64,7 | 81,2 | 97,4 | 130,9 | 164 | 208 | 253 | 310 | |||

| 250 | 41,1 | 53,4 | 66,8 | 83,7 | 100,4 | 134,8 | 172 | 214 | 260 | 319 | |||

| 260 | 55 | 68,8 | 86,3 | 103,4 | 138,6 | 177 | 220 | 267 | 327 | ||||

| 270 | 56,6 | 70,9 | 88,8 | 106,4 | 142,5 | 182 | 224 | 274 | 335 | ||||

| 280 | 58,3 | 73 | 91,4 | 109,4 | 146,3 | 187 | 230 | 281 | 343 | ||||

| 290 | 75 | 93,9 | 112,4 | 150,1 | 192 | 236 | 291 | 360 | |||||

| 300 | 77,1 | 96,5 | 115,4 | 154 | 196 | 241 | 298 | 368 | |||||

| 320 | 101,6 | 121,3 | 161,7 | 206 | 253 | 312 | 380 | ||||||

| 340 | 127,3 | 169,4 | 215 | 265 | 326 | 395 | |||||||

| 360 | 133,3 | 177,1 | 224 | 276 | 340 | 411 | |||||||

| 380 | 184,8 | 234 | 288 | 353 | 428 | ||||||||

| 400 | 192,5 | 243 | 299 | 367 | 444 | ||||||||

| 420 | 252 | 311 | 381 | 460 | |||||||||

| 440 | 262 | 322 | 394 | 477 | |||||||||

| 460 | 271 | 334 | 408 | 493 | |||||||||

| 480 | 281 | 345 | 422 | 509 | |||||||||

| 500 | 290 | 357 | 436 | 526 | |||||||||

Torque Chart for Nickel 200 Stud Bolts

Proper torque ensures a secure and leak-free joint. Over-torquing can cause thread stripping or bolt failure, while under-torquing can lead to joint loosening. Below is a general torque chart for Nickel 200 Stud Bolts based on common sizes and lubrication conditions.

Flange Size |

B16.5 Class 150 RF/ Ring Gaskets |

B16.5 Class 150 FF/ Full Face Gaskets |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Torque / Round (ft-lbs) |

Stud Bolts Tighten Sequence |

Torque / Round (ft-lbs) |

Stud Bolts Tighten Sequence |

|||||||

1st |

2nd |

Final |

Dwg/No. |

Bolt Size |

1st |

2nd |

Final |

Dwg*/No. |

Bolt Size |

|

1/2″ |

10 |

20 |

30 |

4-bolt |

1/2″ |

20 |

40 |

60 |

4-bolt |

1/2″ |

3/4″ |

13 |

27 |

40 |

4-bolt |

1/2″ |

20 |

40 |

60 |

4-bolt |

1/2″ |

1″ |

15 |

30 |

50 |

4-bolt |

1/2″ |

20 |

40 |

60 |

4-bolt |

1/2″ |

1-1/4″ |

20 |

40 |

60 |

4-bolt |

1/2″ |

20 |

40 |

60 |

4-bolt |

1/2″ |

1-1/2″ |

20 |

40 |

60 |

4-bolt |

1/2″ |

20 |

40 |

60 |

4-bolt |

1/2″ |

2″ |

40 |

80 |

120 |

4-bolt |

5/8″ |

40 |

80 |

120 |

4-bolt |

5/8″ |

2-1/2″ |

40 |

80 |

120 |

4-bolt |

5/8″ |

40 |

80 |

120 |

4-bolt |

5/8″ |

3″ |

40 |

80 |

120 |

4-bolt |

5/8″ |

40 |

80 |

120 |

4-bolt |

5/8″ |

3-1/2″ |

40 |

80 |

120 |

8-bolt |

5/8″ |

40 |

80 |

120 |

8-bolt |

5/8″ |

4″ |

40 |

80 |

120 |

8-bolt |

5/8″ |

40 |

80 |

120 |

8-bolt |

5/8″ |

5″ |

60 |

120 |

200 |

8-bolt |

3/4″ |

60 |

120 |

200 |

8-bolt |

3/4″ |

6″ |

60 |

120 |

200 |

8-bolt |

3/4″ |

60 |

120 |

200 |

8-bolt |

3/4″ |

8″ |

60 |

120 |

200 |

8-bolt |

3/4″ |

60 |

120 |

200 |

8-bolt |

3/4″ |

10″ |

95 |

190 |

320 |

12-bolt |

7/8″ |

95 |

190 |

320 |

12-bolt |

7/8″ |

12″ |

95 |

190 |

320 |

12-bolt |

7/8″ |

95 |

190 |

320 |

12-bolt |

7/8″ |

14″ |

147 |

294 |

490 |

12-bolt |

1″ |

147 |

294 |

490 |

12-bolt |

1″ |

16″ |

147 |

294 |

490 |

16-bolt |

1″ |

147 |

294 |

490 |

16-bolt |

1″ |

18″ |

213 |

426 |

710 |

16-bolt |

1-1/8″ |

213 |

426 |

710 |

16-bolt |

1-1/8″ |

20″ |

213 |

426 |

710 |

20-bolt |

1-1/8″ |

213 |

426 |

710 |

20-bolt |

1-1/8″ |

24″ |

300 |

600 |

1,000 |

20-bolt |

1-1/4″ |

300 |

600 |

1,000 |

20-bolt |

1-1/4″ |

Dimension Chart for Nickel 200 Stud Bolts

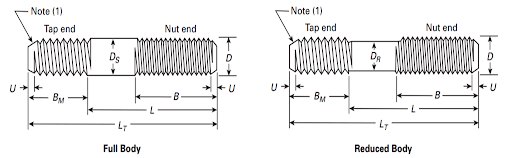

Nickel 200 Stud Bolts are manufactured in two common body types, Full Body and Reduced Body. The selection depends on the application stress requirements and fitting design.

- Full Body Stud Bolts have a consistent diameter equal to the major diameter of the threads.

- Reduced Body Stud Bolts have a shank diameter slightly smaller than the thread's major diameter, offering weight reduction and improved stress distribution under high-temperature applications.

| Nominal Size Diameter, D inch | Tap End Full Thread Length, BM | Umax = 2P | Minimum Nut End Full Thread Length, Bmin | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal | Min. | Max. | UNC & NC-5 Thread | UNF Thread | 8UN Thread | L ≤ 10 | 10 < L ≤ 16 | L > 16 | |

| 1/4 | 0.375 | 0.350 | 0.400 | 0.100 | 0.071 | ... | 0.750 | 1.000 | 1.500 |

| 5/16 | 0.469 | 0.440 | 0.498 | 0.111 | 0.083 | -- | 0.875 | 1.125 | 1.625 |

| 3/8 | 0.563 | 0.532 | 0.594 | 0.125 | 0.083 | -- | 1.000 | 1.250 | 1.750 |

| 7/16 | 0.656 | 0.620 | 0.692 | 0.143 | 0.100 | -- | 1.125 | 1.375 | 1.875 |

| 1/2 | 0.750 | 0.708 | 0.792 | 0.154 | 0.100 | -- | 1.250 | 1.500 | 2.000 |

| 9/16 | 0.844 | 0.802 | 0.896 | 0.167 | 0.111 | -- | 1.375 | 1.625 | 2.125 |

| 5/8 | 0.938 | 0.892 | 0.983 | 0.182 | 0.111 | -- | 1.500 | 1.750 | 2.250 |

| 3/4 | 1.1.25 | 1.075 | 1.175 | 0.200 | 0.125 | -- | 1.750 | 2.000 | 2.500 |

| 7/8 | 1.313 | 1.258 | 1.368 | 0.222 | 0.143 | -- | 2.000 | 2.250 | 2.750 |

| 1 | 1.500 | 1.438 | 1.562 | 0.250 | 0.167 | -- | 2.250 | 2.500 | 3.000 |

| 1 1/8 | 1.688 | 1.625 | 1.750 | 0.286 | 0.167 | 0.250 | 2.500 | 2.750 | 3.250 |

| 1 1/4 | 1.875 | 1.813 | 1.938 | 0.286 | 0.167 | 0.250 | 2.750 | 3.000 | 3.500 |

| 1 3/8 | 2.063 | 2.000 | 2.125 | 0.333 | 0.167 | 0.250 | 3.000 | 3.250 | 3.750 |

| 1 1/2 | 2.250 | 2.188 | 2.313 | 0.333 | 0.167 | 0.250 | 3.250 | 3.500 | 4.000 |

| 1 5/8 | 2.438 | 2.375 | 2.500 | -- | -- | 0.250 | 3.500 | 3.750 | 4.250 |

| 1 3/4 | 2.625 | 2.563 | 2.688 | 0.400 | -- | 0.250 | 3.750 | 4.000 | 4.500 |

| 1 7/8 | 2.813 | 2.750 | 2.875 | -- | -- | 0.250 | 4.000 | 4.250 | 4.750 |

| 2 | 3.000 | 2.925 | 3.075 | 0.444 | -- | 0.250 | 4.250 | 4.500 | 5.000 |

| 2 1/4 | 3.375 | 3.300 | 3.450 | 0.444 | -- | 0.250 | 4.750 | 5.000 | 5.500 |

| 2 1/2 | 3.750 | 3.675 | 3.825 | 0.500 | -- | 0.250 | 5.250 | 5.500 | 6.000 |

| 2 3/4 | 4.125 | 4.050 | 4.200 | 0.500 | -- | 0.250 | 5.750 | 6.000 | 6.500 |

| 3 | 4.500 | 4.425 | 4.575 | 0.500 | -- | 0.250 | -- | 6.500 | 7.000 |

| 3 1/4 | 4.875 | 4.775 | 4.975 | 0.500 | -- | 0.250 | -- | 7.000 | 7.500 |

| 3 1/2 | 5.250 | 5.150 | 5.350 | 0.500 | -- | 0.250 | -- | 7.500 | 8.000 |

| 3 3/4 | 5.625 | 5.525 | 5.725 | 0.500 | -- | 0.250 | -- | 8.000 | 8.500 |

| 4 | 6.000 | 5.900 | 6.100 | 0.500 | -- | 0.250 | -- | 8.500 | |

Applications of Nickel 200 Stud Bolts

Nickel 200 Stud Bolts are widely used in industries where resistance to corrosive environments, especially alkaline & neutral solutions. These bolts are made from commercially pure wrought nickel offering excellent mechanical strength, thermal conductivity & high resistance to caustic alkalis.

- Chemical Processing Industry

- Marine & Offshore Engineering

- Petrochemical & Oil Refining

- Food Processing Equipment

- Electronics & Power Generation

- Aerospace Components

- Nuclear Power Plants

Request a Quote for Nickel 200 Stud Bolts

Need high-performance stud bolts for industrial or high-temperature use? Get in touch by filling out the form with specifications like length, thread style, diameter, and application needs for Nickel 200 Stud Bolts.

Engineered for durability in harsh environments, our Nickel 200 stud bolts are ideal for flange connections, pressure vessels, and chemical processing equipment. Our team is ready to offer a fast turnaround and expert guidance to meet your project goals.

Request QuoteTop Nickel 200 Stud Bolts Manufacturer & Supplier

Nickel 200 Double End Stud Bolt, Nickel 201 Threaded Rods, Nickel 200 Studs Supplier, Nickel 201 Stud Bolt, UNS N02200 / N02201 Stud Bolt, Nickel Alloy 200 Stud Bolts Manufacturer in India.

Nickel 200 Tie Rods, DIN 2.4066 / 2.4068 Stud Bolt, Nickel Alloy 201 Tap End Stud Bolts, Nickel 200 Half Thread Stud Bolts, Nickel 201 Full Threaded Stud Bolt, Nickel 200 Single End Stud Bolt Supplier in Mumbai, India.

Frequently Asked Questions About Nickel 200 Stud Bolts

How do I select the correct size of Nickel 200 Stud Bolt?

Selection depends on application requirements such as pressure, temperature, flange specifications & required torque. Refer to the size and dimension chart for accurate sizing.

Are Nickel 200 Stud Bolts suitable for high-temperature applications?

Yes. Nickel 200 bolts can be used in environments up to 315°C (600°F) & are also suitable for cryogenic applications.

Do Nickel 200 Stud Bolts require any coatings?

Typically, no coating is required due to their corrosion resistance but for added protection in extreme environments, special coatings can be applied.

Can Nickel 200 Stud Bolts be customized?

Yes. Manufacturers like Unifit Fasteners offer customized sizes, threads (UNC/UNF), lengths, and coatings based on your specifications.

What torque should be applied to Nickel 200 Stud Bolts?

Torque depends on bolt diameter, thread pitch & application. Refer to the Nickel 200 torque chart for recommended values.