The Monel fasteners are produced from a nickel-copper superalloy typically containing 29–33 percent copper alongside the balance nickel, with minor additions of carbon, iron, manganese, and silicon. Various grades of Monel bolts can contain up to 67 percent nickel, and some high-strength variants incorporate aluminum or titanium for added tensile performance.

Monel threaded rods are prized for their outstanding corrosion resistance in both acidic and alkaline media, as well as their robust mechanical strength. Monel stud bolts offer excellent formability, allowing them to be shaped into complex geometries, and Monel 400 hex bolts are valued for their attractive finishes and relatively low cost. However, Monel alloys can work-harden rapidly and are known for challenging machinability. Importantly, Monel 400 threaded rods maintain their corrosion resistance even under harsh conditions.

When ASME SF467 UNS N04400 stud bolts come into contact with aluminum, zinc, or iron in aggressive environments, galvanic corrosion of the less noble metal may occur, so compatibility should be confirmed before specifying them. Monel 400 screws also exhibit superior high-temperature performance compared to many stainless steels, with service limits up to 1000 °C. These properties make Monel 400 socket-head cap screws ideal for heat exchangers, pumps, valves, and fittings in marine, chemical processing, and hydrocarbon applications.

Request QuoteMonel 400 Fasteners Manufacturer in India | Monel 400 Bolts & K500 Bolts, Nuts, Screws & Washers

Monel fasteners excel in demanding environments where conventional materials fail, particularly in marine applications, chemical processing, oil refining, and aerospace sectors. At Unifit Fastener, we specialize in manufacturing UNS N04400 Monel 400 and K500 fasteners with various thread configurations—BSW, UNC, BSF, UNF, Metric, or custom specifications as required. Our Monel 400 composition features 63% nickel, 28% copper, with controlled amounts of carbon, manganese, sulfur, and silicon, delivering exceptional performance in highly acidic and corrosive applications.

Our 2.4360 Alloy 400 stud bolts achieve minimum yield strength of 240 MPa and tensile strength of 550 MPa, while set screws demonstrate up to 48% elongation with a melting point of 1300°C. These properties make our Monel threaded rods, washers, and socket head cap screws ideal for marine systems, acid production facilities, and other aggressive environments. Our extensive product line and expert engineering support ensure reliable fastening solutions for the most challenging industrial applications.

Send Your Enquiry

Specification List of Monel Fasteners

A comprehensive specification list outlines the standards, grades, sizes, and mechanical properties of Monel fasteners, enabling buyers to confirm compatibility with project requirements. This ensures precise selection based on ASTM/ASME references, dimensional ranges, and alloy compositions.

| Monel Fasteners ASTM / ANSI | ASTM B865-04 / ASME SB865-04, ASTM B467 / ASME SB467 |

|---|---|

| Grades of Monel Fasteners | Alloy 400 Fasteners Alloy K500 Fasteners |

| Size of Monel Fasteners | M02 to M160 |

| Length of Monel Fasteners | 3 mm to 200 mm |

| Monel Fasteners Threads | BSW, UNC, BSF, UNF, METRIC, or as required |

| Metric Grades | M3, M14, M2.5, M2, M12, M5, M6, M4, M20, M16, M30, M24, M36, M8, M10 etc. |

| Monel Bolts Head Drive | Six-Lobe, Phillips/Slot, Slotted, Phillips etc. |

Types of Monel Fasteners

Familiarity with the various forms of Monel fasteners such as bolts, nuts, studs, screws, washers, and threaded rods helps buyers choose the right component for their specific application. Understanding each type’s unique properties and thread options guarantees optimal performance in corrosive and high-temperature environments.

Monel Bolts

Monel Alloy 400 / K500 Bolts

Monel 400 Structural Bolts ASTM B564

Alloy K500 Heavy Hex Bolts UNS N04400

Nickel Alloy 400 Hex Bolts

High-Performance Alloy K500 Hexagon Head Bolts

Monel 400 Machine Bolts

Alloy K500 T Bolts

Monel 400 Eye Bolt

High-Performance Alloy K500 Foundation Bolts UNS N0550

Monel Alloy 400 J Bolts

Nickel Alloy K500 Button Head Bolt

Monel 400 Anchor Bolts

Alloy K500 Long Bolts

Monel 400 Carriage Bolt

Nickel Alloy K500 Elevator Bolt

Monel 400 Timber Bolts

High-Performance Alloy K500 Square Bolt

Monel 400 Metric Bolt

Alloy K500 Plow Bolts

Monel 400 U Bolts DIN 931

Monel K500 Flange Bolts

Monel Nuts

Monel Alloy 400 / K500 Nuts

Monel 400 Hex Nuts

Alloy K500 Heavy Hex Nuts UNS N04400

Nickel Alloy 400 Wing Nuts

High-Performance Alloy K500 Hexagon Nuts DIN 934

Monel 400 Cap Nuts

Alloy C22 Square Nuts

Monel 400 Coupling Nuts

Alloy K500 Hex Jam Nuts

Monel Alloy 400 T-Nuts

High-Performance Alloy 400 Eye Nuts

Monel 400 Nylock Nuts

Alloy K500 High Tensile Nuts UNS N0550

Nickel Alloy 400 Cage Nuts

Monel 400 Dome Nuts

Alloy K500 Knurled Nuts

Monel 400 Keps-K Lock Nuts

Alloy 400 Machine Hex Nuts

Monel 400 Slotted Nuts

Monel Washers

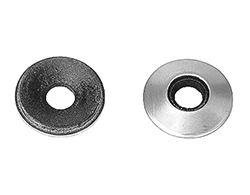

Monel Alloy 400 / K500 Washers

Monel 400 Plain Washers

Alloy K500 Spring Washers UNS N04400

Nickel Alloy 400 Locking Washer

High-Performance Alloy K500 Split Washer

Monel Alloy 400 Flat Washers

Nickel Alloy 400 Ogee Washers

Monel 400 Fender Washer

Alloy K500 Conical Washers

Monel 400 Serrated Washer

High-Performance Alloy 400 Tab Washers

Monel 400 Hex Washer

Alloy K500 Countersunk Washer DIN 433

Monel Alloy 400 Dock Washers

Nickel Alloy 400 Spring Lock Washer

Monel 400 Star Washer

Alloy K500 Bonded Sealing Washer

Monel 400 Square Washers

High-Performance Alloy 400 Belleville Washer

Monel Screws

Monel Alloy 400 / K500 Screw

Monel 400 Socket Set Screw

Alloy K500 Self Drilling Screw UNS N04400

Nickel Alloy 400 Socket Head Cap Screw

High-Performance Alloy K500 Hex Head Screws

Alloy 400 Eye Screw

Nickel Alloy K500 Wing Screw

High-Performance Alloy 400 Self Tapping Screws

Monel 400 Roofing Screw

Monel 400 Phillips Head Screw

Alloy K500 Decking Screw DIN 912

Monel 400 Machine Screw

Nickel Alloy K500 Thumb Screw

Monel 400 Drywall Screws

Alloy 400 Metric Set Screws

High-Performance Alloy K500 Sems Screw

Monel 400 Thread Rolling Screw

Monel Stud Bolts

Monel Alloy 400 / K500 Stud Bolt

Monel 400 Full Threaded Stud Bolts

Alloy K500 Threaded Rod UNS N04400

Nickel Alloy 400 Double Ended Studs

High-Performance Alloy K500 Tap End Stud Bolt

Monel Alloy 400 Tie Rods

High-Performance Alloy 400 Studs

Monel 400 Single End Stud Bolts

Alloy K500 Continuous Threaded Stud

Nickel Alloy 400 Heavy Stud Bolts DIN 976

Monel 400 Material Equivalent Grades

Cross-referencing equivalent grades ensures buyers can match Monel screws with international standards, simplifying procurement and guaranteeing material compatibility across suppliers. This aids in seamless substitution and adherence to project specifications.

| UNS | ASTM | EURO | ALLOY |

|---|---|---|---|

| N04400 | F467 | 2.4360 | 400 |

| N05500 | B865-04 | 2.4375 | K500 |

ASTM F467 Monel Fasteners Mechanical Properties Analysis

Evaluating mechanical properties such as tensile and yield strength, elongation, and modulus of elasticity under ASTM F467 helps buyers select fasteners that withstand design loads and environmental stresses. This analysis underpins reliable performance in critical applications.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength (annealed) | 517-620 MPa | 75-90 ksi |

| Yield strength | 172-345 MPa | 25-50 ksi |

| Modulus of elasticity | 179 GPa | 26000 ksi |

| Poisson’s ratio | 0.32 | 0.32 |

Monel 400 Chemical Composition

Knowing the precise chemical composition, principally 63% nickel, 28–34% copper with controlled carbon, manganese, sulfur, and silicon levels enables buyers to predict corrosion resistance and strength characteristics, ensuring suitability for specific service conditions.

| Element | Content (%) |

|---|---|

| Copper, Cu | 28-34 |

| Nickel, Ni | Remainder |

| Manganese, Mn | 2 max |

| Iron, Fe | 2.5 max |

| Carbon, C | 0.3 max |

| Silicon, Si | 0.5 max |

| Sulphur, S | 0.024 |

Monel 400 Hex Bolt Dimension

Detailed dimensional data for Monel 400 hex bolts, including across-flats width, head thickness, and thread diameter, allows buyers to verify fit and clearance requirements. Accurate sizing is vital for proper assembly and to prevent mechanical interference.

| NOMINAL SIZE (D) | ACROSS THE FLATS F (MAX) | F (MIN) | HEAD THICKNESS H (MAX) | H (MIN) | BODY DIA. D (MAX) | D (MIN) | ACROSS CORNERS C (MAX) | C (MIN) |

|---|---|---|---|---|---|---|---|---|

| m20 | 30.00 | 29.16 | 12.88 | 12.12 | 20.00 | 19.67 | 34.64 | 32.95 |

| m12 | 19.00 | 17.73 | 7.76 | 4.24 | 12.00 | 11.73 | 20.78 | 20.03 |

| m14 | 22.00 | 20.67 | 9.09 | 8.51 | 14.00 | 13.73 | 24.25 | 23.35 |

| m10 | 17.00 | 15.73 | 6.63 | 6.17 | 10.00 | 9.78 | 18.48 | 17.77 |

| m16 | 24.00 | 23.67 | 10.32 | 9.68 | 16.00 | 15.73 | 27.71 | 26.75 |

| m30 | 46.00 | 45.00 | 19.48 | 17.92 | 30.00 | 29.67 | 53.12 | 50.85 |

| m24 | 36.00 | 35.00 | 15.44 | 14.56 | 24.00 | 23.67 | 41.57 | 39.55 |

| m100 | 145.00 | 140.00 | 63.9 | 60.10 | 90.00 | 99.13 | 167.43 | 159.60 |

| m36 | 55.00 | 53.80 | 23.38 | 21.63 | 36.00 | 35.61 | 63.51 | 60.79 |

| m48 | 75.00 | 72.60 | 31.07 | 28.93 | 48.00 | 47.38 | 86.60 | 82.76 |

| m56 | 85.00 | 82.20 | 36.2 | 33.80 | 56.00 | 55.26 | 98.15 | 93.71 |

| m42 | 65.00 | 62.90 | 26.97 | 25.03 | 42.00 | 41.38 | 75.06 | 71.71 |

| m64 | 95.00 | 91.80 | 41.32 | 38.68 | 64.00 | 63.26 | 109.70 | 104.65 |

| m80 | 115.00 | 111.00 | 51.58 | 48.42 | 80.00 | 79.26 | 132.72 | 126.54 |

| m72 | 105.00 | 101.40 | 46.45 | 43.55 | 72.00 | 71.26 | 121.24 | 115.60 |

| m90 | 130.00 | 125.50 | 57.74 | 54.26 | 90.00 | 89.13 | 150.11 | 143.07 |

Size Range of Monel Socket Head Cap Screw

Knowing the nominal size range of Monel socket head cap screws helps buyers select the correct fastener for precise torque application and clearance requirements. Accurate size data ensures compatibility with mating components and tooling.

| Nominal Size | Head Dia (A) | Hex Socket Size (J) | Thread Pitch | Body Dia. and Head Height (D / H) | Socket Length (K) | ||

|---|---|---|---|---|---|---|---|

| Max | Min | Max | Min | ||||

| M8 | 13.00 | 12.57 | 6.00 | 1.25 | 8.00 | 7.78 | 4.3 |

| M4 | 7.00 | 6.64 | 3.00 | 0.70 | 4.00 | 3.82 | 2.00 |

| M3 | 5.50 | 5.20 | 2.50 | 0.5 | 3.00 | 2.86 | 1.3 |

| M10 | 16.00 | 15.57 | 8.00 | 1.5 | 10.00 | 9.78 | 5.50 |

| M5 | 8.50 | 8.14 | 4.00 | 0.8 | 5.00 | 4.82 | 2.70 |

| M6 | 10.00 | 9.64 | 5.00 | 1.0 | 6.00 | 5.82 | 3.30 |

| M12 | 18.00 | 17.57 | 10.00 | 1.75 | 12.00 | 11.73 | 6.60 |

| M20 | 30.00 | 29.48 | 17.00 | 2.5 | 20.00 | 19.67 | 10.70 |

| M16 | 24.00 | 23.48 | 14.00 | 2.0 | 16.00 | 15.73 | 8.80 |

| M24 | 36.00 | 35.38 | 19.00 | 3.0 | 24.00 | 23.67 | 12.90 |

DIN 2.4360 Threaded Rod Dimensions

Clear dimensional specifications for DIN-standard 2.4360 threaded rods enable buyers to verify fit and load-bearing capacity in metric assemblies. This information supports proper design integration and strength calculations.

| Monel Threaded Rod Weight per metre (Kg/m) |

Threaded Rod Thread | Threaded Rod Strength - Class 70 | Threaded Rod Strength - Class 80 | ||

|---|---|---|---|---|---|

| UTS (kN) | 0.2% proof (kN) | UTS (kN) | 0.2% proof (kN) | ||

| 3.83 | M27 | 321.3 | 206.6 | 367.2 | 275.4 |

| 1.31 | M16 | 109.9 | 70.7 | 125.6 | 94.2 |

| 2.05 | M20 | 171.5 | 110.3 | 196.0 | 147.0 |

| 0.72 | M12 | 64.0 | 41.0 | 73.0 | 54.0 |

| 2.96 | M24 | 247.1 | 158.9 | 282.4 | 211.8 |

| 14.65 | M52 | 1230.6 | 791.1 | 1406.4 | 1054.8 |

| 6.84 | M36 | 571.9 | 367.7 | 653.6 | 490.2 |

| 4.70 | M30 | 392.7 | 252.6 | 448.8 | 336.6 |

| 8.14 | M39 | 683.2 | 439.2 | 780.8 | 585.6 |

| 5.78 | M33 | 485.8 | 312.3 | 555.2 | 416.4 |

| 9.38 | M42 | 784.7 | 504.5 | 896.6 | 672.6 |

| 10.90 | M45 | 914.2 | 587.7 | 1044.8 | 783.6 |

| 12.32 | M48 | 1031.1 | 662.9 | 1178.4 | 883.8 |

ASTM F467 Alloy 400 Washer Sizes

Understanding the flat washer’s inner and outer diameters and thickness per ASTM F467 allows buyers to choose washers that provide optimal load distribution and surface protection. Correct sizing prevents fastener pull-through and material damage.

| Size | USS | SAE | ||||

|---|---|---|---|---|---|---|

| Outside Diameter (B) | Inside Diameter (A) | Thickness (C) | Outside Diameter (B) | Inside Diameter (A) | Thickness (C) | |

| #8 | - | - | - | 7/16" | 3/16" | 0.049" |

| #4 | - | - | - | 5/16" | 1/8" | 0.032" |

| #2 | - | - | - | 1/4" | 3/32" | 0.020" |

| #6 | - | - | - | 3/8" | 5/32" | 0.049" |

Dimensions of DIN 2.4360 Hex Nut

Detailed hex nut dimensions, including across-flats width and thickness, ensure buyers can match nuts to corresponding bolts for proper thread engagement. Accurate dimensions are vital for achieving reliable clamping and torque control.

| Diameter* (mm) | Nut Size (mm) | Height (mm) | ||

|---|---|---|---|---|

| Jam Nut | Hex Nut | Nylock Nut | ||

| 8 | 5 | 2.7 | 4 | 5 |

| 5 | 2.5 | 1.6 | 2 | - |

| 5.5 | 3 | 1.8 | 2.4 | 4 |

| 30 | 20 | 10 | 16 | 20 |

| 4 | 2 | 1.2 | 1.6 | - |

| 7 | 4 | 2.2 | 3.2 | 5 |

| 19 | 12 | 6 | 10 | 12 |

| 11 | 7 | 3.5 | 5.5 | - |

| 22 | 14 | 7 | 11 | 14 |

| 13 | 8 | 4 | 6.5 | 8 |

| 24 | 16 | 8 | 13 | 16 |

| 10 | 6 | 3.2 | 5 | 6 |

| 17 | 10 | 5 | 8 | 10 |

| 27 | 18 | 9 | 15 | 18.5 |

Monel Stud Bolts Dimensions

Accurate stud bolt dimensions, including thread diameter, length, and head configuration, ensure proper fit and clamping force in flange and coupling applications. Buyers rely on these specifications to confirm compatibility with mating components and to maintain flange integrity under pressure.

| Stud Bolt Sizes | Monel 400 Studs Length | Nominal Pipe Size | No. of Bolts | Bolt Circle Dia. | OD of Flange | Bolt Holes Dia. | Bolts Dia. | Ring Joint | 0.06 in Raised Face |

|---|---|---|---|---|---|---|---|---|---|

| 3/4 | 3/4 | 4 | 2 3/4 | 3 7/8 | 5/8 | 1/2 | – | 2 1/2 | |

| 1 1/4 | 1 1/4 | 4 | 3 1/2 | 4 5/8 | 5/8 | 1/2 | 3 1/4 | 2 3/4 | |

| 1/2 | 1/2 | 4 | 2 3/8 | 3 1/2 | 5/8 | 1/2 | – | 2 1/4 | |

| 1 1/2 | 1 1/2 | 4 | 3 7/8 | 5 | 5/8 | 1/2 | 3 1/4 | 2 3/4 | |

| 2 | 2 | 4 | 4 3/4 | 6 | 3/4 | 5/8 | 3 3/4 | 3 1/4 | |

| 1 | 1 | 4 | 3 1/8 | 4 1/4 | 5/8 | 1/2 | 3 | 2 1/2 | |

| 2 1/2 | 2 1/2 | 4 | 5 1/2 | 7 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 3 1/2 | 3 1/2 | 8 | 7 | 8 1/2 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 4 | 4 | 8 | 7 1/2 | 9 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 3 | 3 | 4 | 6 | 7 1/2 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 5 | 5 | 8 | 8 1/2 | 10 | 7/8 | 3/4 | 4 1/4 | 3 3/4 | |

| 8 | 8 | 8 | 11 3/4 | 13 1/2 | 7/8 | 3/4 | 4 3/4 | 4 1/4 | |

| 6 | 6 | 8 | 9 1/2 | 11 | 7/8 | 3/4 | 4 1/2 | 4 | |

| 10 | 10 | 12 | 14 3/4 | 16 | 1 | 7/8 | 5 | 4 1/2 | |

| 14 | 14 | 12 | 18 3/4 | 21 | 1 1/8 | 1 | 5 3/4 | 5 1/4 | |

| 12 | 12 | 12 | 17 | 19 | 1 | 7/8 | 5 1/4 | 4 3/4 | |

| 16 | 16 | 16 | 21 1/4 | 23 1/2 | 1 1/8 | 1 | 5 3/4 | 5 1/4 | |

| 20 | 20 | 20 | 25 | 27 1/2 | 1 1/4 | 1 1/8 | 6 3/4 | 6 1/4 | |

| 18 | 18 | 16 | 22 3/4 | 25 | 1 1/4 | 1 1/8 | 6 1/4 | 5 3/4 | |

| 24 | 24 | 20 | 29 1/2 | 32 | 1 1/4 | 1 1/4 | 7 1/4 | 6 3/4 |

ASME SF467 UNS N04400 Screw Size Chart

A comprehensive screw size chart per ASME SF467 gives buyers quick reference for nominal diameters, thread pitches, and lengths of Monel 400 screws. This chart simplifies ordering and ensures the correct screw selection for high-corrosion and high-temperature environments.

Screw Sizes

| Screw Size | Fractions | Decimals | Millimeter |

|---|---|---|---|

| #1 | 1/16" | 0.0625" | 1.58750 |

| #2 | 5/64" | 0.078125" | 1.98437 |

| #3 | 3/32" | 0.09375" | 2.38125 |

| #4 | 7/64" | 0.109375" | 2.77812 |

| #5 | 1/8" | 0.125" | 3.17500 |

| #6 | 9/64" | 0.140625" | 3.57187 |

| #8 | 5/32" | 0.15625" | 3.96875 |

| #10 | 3/16" | 0.1875" | 4.76250 |

| #12 | 7/32" | 0.21875" | 5.55625 |

| 1/4 | 1/4" | 0.250" | 6.35000 |

| 5/16 | 5/16" | 0.3125" | 7.93750 |

| 3/8 | 3/8" | 0.375" | 9.52500 |

Standard Threads

| UNC | UNF |

|---|---|

| 1/4 x 20 | 1/4 x 28 |

| 5/16 x 18 | 5/16 x 24 |

| 3/8 x 16 | 3/8 x 24 |

| 7/16 x 14 | 7/16 x 20 |

| 1/2 x 13 | 1/2 x 20 |

| 5/8 x 11 | 5/8 x 18 |

| 3/4 x 10 | 3/4 x 16 |

| 7/8 x 9 | 7/8 x 14 |

| 1 x 8 | 1 x 14 |

Monel Bolts Torque

Providing recommended torque values for Monel bolts helps buyers achieve optimal clamping force without risking fastener yield or joint failure. Correct torque guidance ensures reliable sealing and structural integrity, particularly important in marine and chemical processing equipment.

| Nominal Diameter (in) | Threads/in | Torque ft-lb (Dry) | Torque ft-lb (Lubricated) |

|---|---|---|---|

| 1/4" | 20 | 4.2 | 3.1 |

| 28 | 4.7 | 3.5 | |

| 5/16" | 18 | 8.5 | 6.4 |

| 24 | 9.4 | 7.1 | |

| 3/8" | 16 | 15.1 | 11.3 |

| 24 | 17.1 | 12.8 | |

| 7/16" | 14 | 24.2 | 18.1 |

| 20 | 27.0 | 20.3 | |

| 1/2" | 13 | 36.9 | 27.6 |

| 9/16" | 12 | 53.2 | 39.9 |

| 18 | 59.3 | 44.5 | |

| 5/8" | 11 | 73.4 | 55.1 |

| 18 | 83.2 | 62.4 | |

| 3/4" | 10 | 145 | 109 |

| 7/8" | 9 | 210 | 158 |

| 14 | 232 | 174 | |

| 1" | 8 | 315 | 236 |

| 14 | 353 | 265 | |

| 1-1/4" | 7 | 548 | 411 |

| 12 | 607 | 455 | |

| 1-1/2" | 6 | 954 | 715 |

| 12 | 1073 | 805 |

*Calculated from a Yield Strength of 45ksi

Monel Alloy 400 Bolts Price List

A detailed price list of Monel Alloy 400 bolts, showing cost per size and grade, empowers buyers to compare supplier rates and budget accurately. Transparent pricing aids in procurement planning and supports cost negotiations while ensuring access to quality fasteners.

| Description | Price (₹) |

|---|---|

| DIN912 Monel 400 M5X30 Hex Socket Cap Head Screw | ₹1.68–₹2.02 (US $0.02–0.024) |

| Monel 400 T Head Bolt for Solar Mounting | ₹0.84–₹25.20 (US $0.01–0.3) |

| DIN 2.4360 Stud Bolt | ₹0.84–₹16.80 (US $0.01–0.2) |

| Monel Hex Nut | ₹840.00 (US $10) |

| 2.4360 N04400 High Strength Hex Bolt | ₹8.40 (US $0.1) |

| M6 M10 Monel 400 Stud Bolt | ₹0.084–₹75.60 (US $0.001–0.9) |

| M4 M16 Monel 400 Hex Flange Nut | ₹0.084–₹75.60 (US $0.001–0.9) |

| UNS N04400 Fasteners | ₹8.40–₹84.00 (US $0.1–1) |

| DIN934 Monel 400 Hex Nuts | ₹67.20–₹168.00 (US $0.8–2) |

Frequently Asked Questions About Monel Fasteners

What are Monel fasteners?

Monel fasteners are high-performance components such as bolts, nuts, screws, studs, and washers, made from Monel, a nickel-copper alloy renowned for exceptional corrosion resistance, strength, and durability in marine, chemical, and aerospace applications.

What is Monel used for?

Monel is widely employed in marine engineering (propeller shafts, valves, pumps), chemical processing (acid-handling equipment), oil and gas (oil well tools, refineries), aerospace (coatings, fasteners), and musical instruments, owing to its corrosion and temperature resistance.

Is Monel better than titanium?

Monel offers superior corrosion resistance and strength compared to titanium but is heavier and less heat-resistant. Titanium excels in strength-to-weight ratio and high-temperature stability, making each alloy better suited to different applications.

Is Monel stronger than steel?

Yes. Monel alloys demonstrate higher tensile strength (up to 125,000 psi cold-worked) and better toughness than many stainless steels, maintaining strength and ductility under extreme temperatures where steel may embrittle.