Monel 400 Hex Bolts Manufacturers & Suppliers in India

Unifit Fasteners provides high-performance Monel 400 hex bolts which are designed to be used in areas where the strength and resistance to corrosion cannot be compromised. These bolts are made of high-quality monel 400, an alloy of nickel and copper, which is much more durable in high-stress industrial service. They can survive in acidic, alkaline and salt-laden environments and hence are a reliable option in the most vital areas.

Our Monel 400 Hex Bolts have been made to last longer, having a stable nature in a broad temperature range, which remains between the sub-zero environment and the high temperatures. This renders them applicable in marine engineering, chemical processing, heat exchangers, oil and gas systems and equipment which are exposed to hydrofluoric acid. Every bolt undergoes fabrication to provide outstanding tensile and wear resistance and chloride-induced cracking of stress.

At Unifit Fasteners, all bolts are manufactured using precise machining so as to have the right dimensions, good finishing, and easy fit. To suit the project requirements, we provide tailored sizes and specifications to serve as a secure and dependable fastening solution to the most extreme applications. Our Monel 400 Hex Bolts offer a reliable and stable workload performance with a consistent quality and a focus on customer needs, which makes them a reliable option in the industry that requires uncompromised quality of performance.

Monel 400 Heavy Hex Head Bolt Stockist, Alloy 400 Hexagonal Bolt, Monel 400 Hex Bolt Manufacturers, 400 Monel Alloy Hex Shoulder Bolt, Monel 400 Hex Bolt Suppliers.

Request QuoteTable of Contents

- What is a Monel 400 Hex Bolt?

- Why Choose Monel 400 Hex Bolts from Unifit?

- Types of Monel 400 Hex Bolts

- Monel 400 Hex Bolt Head Size Chart

- Monel 400 Hex Bolt Dimensions

- Monel 400 Hex Bolts Specification

- Equivalent Grades Of Monel 400 Hex Bolts

- Chemical Composition of Monel 400 Hex Bolts

- Mechanical Properties of Alloy 400 Hex Bolts

- Monel 400 Hex Bolt Dimension Chart

- 400 Monel Heavy Hex Bolt Dimensions

- Monel 400 Hex Bolts Weight Chart

- Monel 400 Hex Bolts Torque Chart

- Ready Stock Of Monel 400 Hex Bolts

- Industrial Applications of Monel 400 Hex Bolts

- Frequently Asked Questions About Monel 400 Hex Bolts

What is a Monel 400 Hex Bolt?

Monel 400 Hex Bolts are tough, high-performance fasteners crafted from the nickel-copper alloy Monel 400, known for its exceptional corrosion resistance and durability. These ASTM F467 bolts feature a hex-shaped head, making them easy to tighten or remove using common tools. Built to handle aggressive and corrosive environments, they are widely used in marine systems, chemical plants, and various industrial setups where long-term strength and reliability are essential.

Alloy 400 Hex Bolts, Monel 400 Hexagon Bolt, Monel Alloy 400 Hex Head Bolts, Manufacturer of Monel 400 Heavy Hex Bolts, Monel 400 Flange Hex Bolt, Monel 400 Hex Bolts, Monel 400 Hex Bolts Manufacturers in India.

Why Choose Monel 400 Hex Bolts from Unifit?

Unifit Fastener stands out for its precision-engineered Monel 400 Hex Bolts, designed to perform under extreme corrosion, pressure, and temperature. Manufactured using premium UNS N04400 alloy, our bolts are ideal for marine, chemical, and offshore industries.

- Exceptional corrosion resistance

- Consistent mechanical strength

- Custom sizing & quick turnaround

- Stringent in-house testing & certifications

When it comes to reliability and longevity, Unifit’s Monel 400 Hex Bolts deliver unmatched performance for mission-critical applications.

Send Your Enquiry

Types of Monel 400 Hex Bolts

Monel 400 Hex Bolts are available in a wide range of types each tailored to suit specific mechanical, structural or corrosion-resistant requirements in critical applications such as marine, chemical and offshore industries. Check below for the complete list of available variants offered by Unifit:

- Monel 400 Hex Head Shoulder Bolts

- Monel 400 Threaded Hex Bolts

- Monel Alloy 400 Stud Hex Bolt

- Monel 400 Hex High Tensile Bolt

- Monel 400 Slotted Hex Bolts

- Monel 400 Heavy Hex Bolt

- Monel 400 Hex Structural Bolts

- Monel 400 Tension Control Hex Bolts

- Monel Alloy 400 Hex Tap Bolts

- Monel 400 Metric Hex Bolt

- Monel 400 Hex Socket Bolts

- Monel 400 Hexagon Flange Bolt

Monel 400 Hex Bolt Head Size Chart

Below is the standard head size chart for Monel 400 Hex Bolts. These dimensions ensure compatibility with industry-standard tools and precise fitting during assembly or maintenance:

| Bolt Diameter (inches) | Hex Head Size (inches) |

|---|---|

| 1/4" | 7/16" |

| 5/16" | 1/2" |

| 3/8" | 9/16" |

| 7/16" | 5/8" |

| 1/2" | 3/4" |

| 9/16" | 13/16" |

| 5/8" | 15/16" |

| 3/4" | 1 1/8" |

| 7/8" | 1 5/16" |

| 1" | 1 1/2" |

Monel 400 Hex Bolt Dimensions

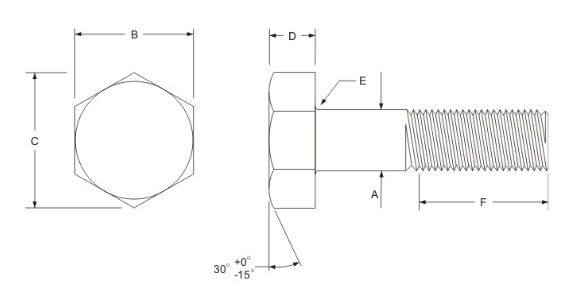

Below is the detailed chart of standard dimensions for Monel 400 Hex Bolts covering nominal sizes, thread counts, head dimensions and minimum threaded lengths crucial for precise engineering applications:

| Nominal Size | Decimal (in.) | Threads per Inch | Head Width Across Flats | Head Width Across Corners | Head Height (Basic) | Min Threaded Length ≤6" | Min Threaded Length >6" |

|---|---|---|---|---|---|---|---|

| 1/4 | 0.2500 | UNC 20 / UNF 28 | 7/16 | 1/2 | 5/32 | 3/4 | 1 |

| 5/16 | 0.3125 | 18 / 24 | 1/2 | 9/16 | 13/64 | 7/8 | 1 1/8 |

| 3/8 | 0.3750 | 16 / 24 | 9/16 | 41/64 | 15/64 | 1 | 1 1/4 |

| 7/16 | 0.4375 | 14 / 20 | 5/8 | 45/64 | 9/32 | 1 1/8 | 1 3/8 |

| 1/2 | 0.5000 | 13 / 20 | 3/4 | 55/64 | 5/16 | 1 1/4 | 1 1/2 |

| 9/16 | 0.5625 | 12 / 18 | 13/16 | 59/64 | 23/64 | 1 3/8 | 1 5/8 |

| 5/8 | 0.6250 | 11 / 18 | 15/16 | 1 1/16 | 25/64 | 1 1/2 | 1 3/4 |

| 3/4 | 0.7500 | 10 / 16 | 1 1/8 | 1 9/32 | 15/32 | 1 3/4 | 2 |

| 7/8 | 0.8750 | 9 / 14 | 1 5/16 | 1 31/64 | 35/64 | 2 | 2 1/4 |

| 1 | 1.0000 | 8 / 12 | 1 1/2 | 1 45/64 | 39/64 | 2 1/4 | 2 1/2 |

| 1 1/8 | 1.1250 | 7 / 12 | 1 11/16 | 1 29/32 | 11/16 | 2 1/2 | 2 3/4 |

| 1 1/4 | 1.2500 | 7 / 12 | 1 7/8 | 2 7/64 | 25/32 | 2 3/4 | 3 |

| 1 3/8 | 1.3750 | 6 / 12 | 2 1/16 | 2 21/64 | 27/32 | 3 | 3 1/4 |

| 1 1/2 | 1.5000 | 6 / 12 | 2 1/4 | 2 17/32 | 1 5/16 | 3 1/4 | 3 1/2 |

Monel 400 Hex Bolts Specification

| Specifications | ASTM F467 / ASME SF467 |

|---|---|

| Standard | ISO, ASTM, DIN, JIS, IS, GB, BS, and all International Standards |

| Diameter | M3 to M56 up to 500 MM |

| DIN Standard | B.S. DIN 931, DIN 933, DIN 912, DIN 934, DIN 6923, DIN 603, DIN 7981, DIN 970, DIN916, DIN 7982, DIN 7985, DIN 913 |

| UTS | NPT, UNS, UNF, UNC, UNEF, NPTF |

| ISO | ISO 4033, ISO 4032, ISO 7380, ISO 4017, JIS standards |

| Threads | UNF, BSW, BSF, METRIC, UNC, or as required |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

Equivalent Grades Of Monel 400 Hex Bolts

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

Chemical Composition of Monel 400 Hex Bolts

| Elements | Ni + Co | Fe | Cr | Nb + Ta | Mo | Ti | Co | Al | Mn | Si | Cu | C | P | S | B |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min % | 50 | – | 17.0 | 4.75 | 2.80 | 0.65 | – | 0.20 | – | – | – | – | – | – | – |

| Max % | 55 | Bal | 21.0 | 5.50 | 3.30 | 1.15 | 1.0 | 0.80 | 0.35 | 0.35 | 0.30 | 0.08 | 0.015 | 0.015 | 0.006 |

Mechanical Properties of Alloy 400 Hex Bolts

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

Monel 400 Hex Bolt Dimension Chart

| Diameter (D) | Thread Lengths (T) | Across the Flats (F) | Body Diameter (D) | Head Height (H) | Across the Corners © | |||||

| < 6” | > 6” | MAXIMUM | MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | MINIMUM | |

| 1 | 2.25 | 2.5 | 1.625 | 1.575 | 1.022 | 0.976 | 0.7 | 0.591 | 1.876 | 1.796 |

| 1/2 | 1.25 | 1.5 | 0.875 | 0.85 | 0.515 | 0.482 | 0.364 | 0.302 | 1.01 | 0.969 |

| 2 | 4.25 | 4.5 | 3.125 | 3.025 | 2.039 | 1.964 | 1.388 | 1.175 | 3.608 | 3.449 |

| 3 | 6.25 | 6. | 4.625 | 4.475 | 3.081 | 2.961 | 2.06 | 1.815 | 5.34 | 5.102 |

| 3/4 | 1.75 | 2 | 1.25 | 1.212 | 0.768 | 0.729 | 0.524 | 0.455 | 1.443 | 1.383 |

| 5/8 | 1.5 | 1.75 | 1.062 | 1.031 | 0.642 | 0.605 | 0.444 | 0.378 | 1.227 | 1.175 |

| 7/8 | 2 | 2.25 | 1.438 | 1.394 | 0.895 | 0.852 | 0.604 | 0.531 | 1.66 | 1.589 |

| 1 1/2 | 3.25 | 3.5 | 2.375 | 2.3 | 1.531 | 1.47 | 1.036 | 0.902 | 2.742 | 2.622 |

| 1 1/4 | 2.75 | 3 | 2 | 1.938 | 1.277 | 1.223 | 0.876 | 0.749 | 2.309 | 2.209 |

| 1 1/8 | 2.5 | 2.75 | 1.812 | 1.756 | 1.149 | 1.098 | 0.78 | 0.658 | 2.093 | 2.002 |

| 1 3/4 | 3.75 | 4 | 2.75 | 2.662 | 1.785 | 1.716 | 1.196 | 1.054 | 3.175 | 3.035 |

| 1 3/8 | 3 | 3.25 | 2.188 | 2.119 | 1.404 | 1.345 | 0.94 | 0.81 | 2.526 | 2.416 |

| 2 1/2 | 5.25 | 5.5 | 3.875 | 3.75 | 2.559 | 2.461 | 1.708 | 1.479 | 4.474 | 4.275 |

| 2 1/4 | 4.75 | 5 | 3.5 | 3.388 | 2.305 | 2.214 | 1.548 | 1.327 | 4.041 | 3.862 |

| 2 3/4 | 5.75 | 6 | 4.25 | 4.112 | 2.827 | 2.711 | 1.869 | 1.632 | 4.907 | 4.688 |

400 Monel Heavy Hex Bolt Dimensions

| NOMINAL SIZE (D) | ACROSS THE FLATS | HEAD THICKNESS | DIAMETER OF BODY | ACROSS Bolt CORNERS | ||||

| F (MAXIMUM) | F (MINIMUM) | H (MAXIMUM) | H (MINIMUM) | D (MAXIMUM) | D (MINIMUM) | C (MAXIMUM) | C (MINIMUM) | |

| m10 | 17.00 | 15.73 | 6.63 | 6.17 | 10.00 | 9.78 | 18.48 | 17.77 |

| m12 | 19.00 | 17.73 | 7.76 | 4.24 | 12.00 | 11.73 | 20.78 | 20.03 |

| m14 | 22.00 | 20.67 | 9.09 | 8.51 | 14.00 | 13.73 | 24.25 | 23.35 |

| m16 | 24.00 | 23.67 | 10.32 | 9.68 | 16.00 | 15.73 | 27.71 | 26.75 |

| m20 | 30.00 | 29.16 | 12.88 | 12.12 | 20.00 | 19.67 | 34.64 | 32.95 |

| m24 | 36.00 | 35.00 | 15.44 | 14.56 | 24.00 | 23.67 | 41.57 | 39.55 |

| m30 | 46.00 | 45.00 | 19.48 | 17.92 | 30.00 | 29.67 | 53.12 | 50.85 |

| m36 | 55.00 | 53.80 | 23.38 | 21.63 | 36.00 | 35.61 | 63.51 | 60.79 |

| m42 | 65.00 | 62.90 | 26.97 | 25.03 | 42.00 | 41.38 | 75.06 | 71.71 |

| m48 | 75.00 | 72.60 | 31.07 | 28.93 | 48.00 | 47.38 | 86.60 | 82.76 |

| m56 | 85.00 | 82.20 | 36.2 | 33.80 | 56.00 | 55.26 | 98.15 | 93.71 |

| m64 | 95.00 | 91.80 | 41.32 | 38.68 | 64.00 | 63.26 | 109.70 | 104.65 |

| m72 | 105.00 | 101.40 | 46.45 | 43.55 | 72.00 | 71.26 | 121.24 | 115.60 |

| m80 | 115.00 | 111.00 | 51.58 | 48.42 | 80.00 | 79.26 | 132.72 | 126.54 |

| m90 | 130.00 | 125.50 | 57.74 | 54.26 | 90.00 | 89.13 | 150.11 | 143.07 |

| m100 | 145.00 | 140.00 | 63.9 | 60.10 | 90.00 | 99.13 | 167.43 | 159.60 |

Monel 400 Hex Bolts Weight Chart

MM THREADS AS PER IS 1363/67 |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Fasteners APPROXIMATE WEIGHT IN KGS FOR 100 NOS |

||||||||||

Monel 400 LENGTH |

D I A M E T E R |

|||||||||

M 5 |

M 6 |

M 8 |

M 10 |

M 12 |

M 14 |

M 16 |

M 18 |

M 20 |

M 22 |

|

| 16 mm | 0.448 | 0.743 | 1.590 | 3.211 | ||||||

| 20 mm | 0.598 | 0.812 | 1.711 | 3.411 | 4.892 | |||||

| 25 mm | 0.660 | 0.897 | 1.871 | 3.660 | 5.252 | 8.170 | ||||

| 30 mm | 0.737 | 1.010 | 2.070 | 3.912 | 5.574 | 9.690 | 10.707 | 18.657 | ||

| 35 mm | 0.804 | 1.120 | 2.271 | 4.223 | 5.974 | 10.000 | 11.416 | 16.026 | 19.608 | |

| 40 mm | 0.881 | 1.230 | 2.470 | 4.533 | 6.410 | 10.288 | 12.107 | 16.667 | 20.747 | |

| 45 mm | 0.958 | 1.340 | 2.671 | 4.840 | 6.859 | 10.504 | 12.821 | 17.241 | 21.739 | |

| 50 mm | 1.030 | 1.450 | 2.870 | 5.155 | 7.299 | 11.261 | 13.624 | 17.857 | 22.727 | 28.409 |

| 55 mm | 1.560 | 3.071 | 5.464 | 7.740 | 11.628 | 14.409 | 18.868 | 23.810 | 30.120 | |

| 60 mm | 1.670 | 3.270 | 5.774 | 8.183 | 12.255 | 15.244 | 20.000 | 25.126 | 32.051 | |

| 65 mm | 1.781 | 3.472 | 6.083 | 8.621 | 12.626 | 16.026 | 21.008 | 26.455 | 34.014 | |

| 70 mm | 1.890 | 3.671 | 6.394 | 9.058 | 12.987 | 16.835 | 22.124 | 27.778 | 35.461 | |

| 75 mm | 2.000 | 3.873 | 6.702 | 9.506 | 13.228 | 17.606 | 23.256 | 29.070 | 39.063 | |

| 80 mm | 2.111 | 4.072 | 7.013 | 10.000 | 13.889 | 18.248 | 24.510 | 30.303 | 40.000 | |

| 90 mm | 4.472 | 7.634 | 10.917 | 14.925 | 19.841 | 26.042 | 33.113 | 41.667 | ||

| 100 mm | 4.873 | 8.251 | 11.820 | 16.340 | 21.459 | 27.778 | 35.714 | 46.296 | ||

| 110 mm | 8.881 | 12.723 | 17.730 | 23.041 | 31.250 | 38.168 | 47.170 | |||

| 120 mm | 9.506 | 13.624 | 18.797 | 24.631 | 32.895 | 40.984 | 50.000 | |||

| 130 mm | 10.101 | 14.535 | 20.000 | 26.316 | 34.722 | 43.478 | 52.632 | |||

| 140 mm | 10.707 | 15.432 | 20.833 | 27.933 | 35.461 | 46.296 | 55.556 | |||

| 150 mm | 11.312 | 16.340 | 22.222 | 29.412 | 37.594 | 48.544 | 58.824 | |||

| 160 mm | 11.905 | 17.241 | 24.272 | 31.056 | 40.984 | 50.505 | 61.728 | |||

| 170 mm | 12.500 | 18.116 | 32.680 | 53.191 | 64.935 | |||||

| 180 mm | 13.123 | 19.011 | 26.882 | 34.247 | 55.556 | 67.568 | ||||

| 190 mm | 13.736 | 19.920 | 35.971 | 58.140 | 70.423 | |||||

| 200 mm | 14.327 | 20.833 | 29.586 | 37.594 | 49.020 | 60.976 | 73.529 | |||

| 220 mm | 15.528 | 22.624 | 40.650 | 65.789 | 79.365 | |||||

| 240 mm | 16.722 | 24.510 | 43.860 | 71.429 | 84.746 | |||||

| 250 mm | 17.301 | 25.381 | 45.455 | 74.627 | 87.719 | |||||

| 260 mm | 17.921 | 26.316 | 47.170 | 76.923 | 90.909 | |||||

| 280 mm | 19.157 | 28.090 | 50.505 | 81.967 | 98.039 | |||||

| 300 mm | 20.325 | 29.940 | 53.763 | 87.719 | 104.167 | |||||

| 320 mm | 31.646 | 56.818 | 92.593 | |||||||

| 340 mm | 33.557 | 60.241 | 98.039 | |||||||

| 360 mm | 35.211 | 63.291 | 104.167 | |||||||

| 380 mm | 37.037 | 66.667 | 108.696 | |||||||

| 400 mm | 39.063 | 69.444 | 113.636 | |||||||

Monel 400 Hex Bolts Torque Chart

Below is a reference table outlining the recommended torque values for Monel 400 hex bolts based on common bolt sizes. These values ensure proper clamping force without compromising the material integrity:

| Bolt Size (inches) | Thread Pitch (UNC) | Torque (Nm) | Torque (lb-ft) |

|---|---|---|---|

| 1/4" | 20 TPI | 8.5 | 6.3 |

| 5/16" | 18 TPI | 17 | 12.5 |

| 3/8" | 16 TPI | 30 | 22.1 |

| 7/16" | 14 TPI | 48 | 35.4 |

| 1/2" | 13 TPI | 74 | 54.6 |

| 9/16" | 12 TPI | 106 | 78.2 |

| 5/8" | 11 TPI | 146 | 107.7 |

| 3/4" | 10 TPI | 259 | 191 |

| 7/8" | 9 TPI | 373 | 275 |

| 1" | 8 TPI | 562 | 415 |

Ready Stock Of Monel 400 Hex Bolts

| ASTM F468 Monel Alloy 400 Hex Cap Screw | Monel 2.4360 Hex Bolts |

| Monel Alloy 400 Fasteners | Monel 400 Fasteners |

| Nickel Alloy 400 Hex Cap Screw | Monel 400 High Tensile M6 Hex Bolts |

| ASTM F467 Monel 400 Heavy Hex Bolt | Monel® Alloy 400 Heavy Hex Bolts M6 X 25mm Manufacturer |

| Monel 400 Metric Hex Bolts | Nickel Alloy 400 Hex Head Shoulder Bolt |

| 400 Alloy Hexagon Screw Head Bolts | Monel 400 Long Hex Bolt |

| ASTM F467 Monel 400 Hex Bolt Stockist | Monel® Alloy 400 Industrial Hex Bolts |

| Monel 400 Heavy Hex Bolt | 400 Monel Flanged Hex Bolts |

| Monel 400 Industrial Hex Bolt | Monel 400 Heavy Hex Bolt Stockist |

| Monel UNS N04400 Hex Bolt | Monel Alloy 400 Hex Tap Bolts |

| Alloy 400 Hex Head Shoulder Bolt | UNS N04400 Heavy Hex Bolt |

| 400 Monel Hex Bolts Stock At Best Price | Monel 400 Hex Head Shoulder Bolt |

| 400 Monel M6 Hex Bolts | Alloy 400 High Tensile Hex Bolts |

Industrial Applications of Monel 400 Hex Bolts

Monel 400 Hex Bolts are trusted across industries where superior corrosion resistance, mechanical strength and longevity are essential. These bolts are particularly favored in applications where stainless steel fasteners may fail due to chloride-induced corrosion making Monel 400 hex bolts a long-term, cost-effective choice in critical assemblies.

- Marine

- Chemical Processing

- Oil & Gas

- Aerospace

- Power Generation (including Nuclear)

- Pharmaceutical

- Food & Beverage

- Pulp & Paper

- Desalination Plants

- Automotive

Get an Instant Quote on Monel 400 Hex Bolts

Looking for reliable, corrosion-resistant Monel 400 Hex Bolts at competitive prices? You're in the right place. At Unifit Fastener, we combine premium quality with fast response times and global shipping.

Whether it’s a custom order or bulk requirement, we’ll tailor the quote to your exact needs.

- Quick turnaround

- Expert support

- Hassle-free delivery

Fill out the form below and we’ll get back to you with a quote that works - fast, fair and accurate.

Add for sleek lead form here

Trusted Monel 400 Hex Bolts Suppliers, Manufacturers & Exporters

Unifit Fastener is one of the trusted Monel 400 Hex Bolts suppliers, manufacturers and exporters in India delivering high-performance fastening solutions for marine, chemical and oil & gas industries. As a leading Monel 400 Hex Bolts manufacturer, we offer precision-forged, corrosion-resistant bolts in standard and custom specifications. Backed by global quality standards and fast worldwide shipping, Unifit is a preferred choice among top Monel 400 Hex Bolts exporters serving clients across Asia, Europe, the Middle East and beyond.

Frequently Asked Questions About Monel 400 Hex Bolts

Are Monel 400 Hex Bolts suitable for high-temperature applications?

Yes, they can perform well in high-temperature environments up to 480°C (900°F) making them suitable for heat exchangers and boilers.

Can I get custom sizes for Monel 400 Hex Bolts?

Absolutely, Unifit offers customization in sizes, thread pitch and head styles as per your project requirements.

How are Monel 400 Hex Bolts different from stainless steel bolts?

Unlike stainless steel, Monel 400 offers superior resistance to acids, alkalis and saltwater making it a better choice for harsh environments.

Do you provide test certificates with the bolts?

Yes, all our bolts come with full traceability and test certifications including material, PMI and mechanical properties.

Monel 400 Hex Bolts, Alloy UNS N04400 Hexagon Bolts, Monel 2.4360 Heavy Hex Bolts, Monel 400 Full Threaded Hex Bolts, Monel 400 Hex Flange Bolts, Monel 400 Hex Machine Bolts, Monel 400 Hex Head Shoulder Bolts, Monel Alloy 400 Hex Tap Bolts, Monel 400 Hexagonal Head Bolt Supplier in Mumbai, India.

Request Quote