Nickel is the most diverse metal and can be combined with other materials to form very powerful and high performance materials. Due to their great corrosion resistance, Nickel Alloy Fasteners of Unifit Fasteners are highly preferred in the context of where reliability is not a compromise. These are fasteners such as our own high quality nickel alloy bolts, which do astonishingly well in high temperature conditions where other steel alloy grades would oxidise or wear out.

In addition to their high resistance to oxidation, nickel alloy bolts have some resistance to reducing media and thus can be used in adverse industrial conditions. Commercially pure grades such as Nickel 200 Fasteners are generally employed at lower temperatures below 600 o C and they are highly resistant to caustic alkaline conditions. On the same note, UNS N02200 Hex Bolts provide good stability in dry fluorine, hydroxides and other harsh chemical environments.

Nickel 201 Fasteners contain less carbon than Nickel 200, making them less hard and less graphitization resistant in high temperatures. UNS N02201 Studs is an effective eliminator of intergranular embrittlement, and this is a frequent problem in traditional steels when they are subjected to temperatures exceeding 315 o C. This causes nickel alloy studs to be a reliable option where structural integrity over a long period is important.

In the case of Unifit Fasteners, you receive nickel alloy nuts, bolts, studs and threaded rods that remain strong, stable as well as corrosion proof even in the most hostile industrial settings.

Request QuoteThe Nickel 200 fasteners have found wide application in chemical manufacturing plants and food processing industries, as they have a very good resistance to corrosion. We produce different types of ASTM F2281 UNS N02200 Ni 200 fasteners at Unifit Fastener, such as hex bolts, socket cap screws, nickel 200 hex nuts, washers, threaded rods, studs, and U-bolts. These fasteners are of ASTM B160 standards, which are of the best quality and reliable.

Our 2.4066 nickel 200 stud bolts consist of a mixture of close to 99 per cent nickel metals, copper, iron, manganese, carbon, silicon and sulphur in specific proportions. In spite of the fact that ASTM F2281 nickel alloy bolts are likely to cost more, their high level of corrosion resistance makes them useful in sensitive industrial works where durability and performance are very important.

The Nickel 200 UNS N02200 hex nuts are particularly renowned because of their design, which is geometrical and capable of high torque. Unifit Fasteners, as a major producer and distributor, manufactures nickel alloy threaded rods, as well as a complete assortment of nickel 200 fasteners in different sizes and forms. To obtain the specifications and prices of nickel 200 socket head cap screws, hex bolts and any other fasteners, then contact us.

Table of Contents

- Nickel Alloy Fasteners Specification

- Send Your Enquiry

- Types of Nickel Alloy Fasteners

- Equivalent Grade of Nickel Screws

- Physical Properties of UNS N02200 Fasteners

- Nickel Alloy Hex Bolts Mechanical Properties

- Corrosion Resistance Of Nickel Screws

- Pure Nickel Bolt Torque Chart

- Size Chart for Nickel Alloy Fasteners

- Dimension Chart of Pure Nickel Stud Bolt

- Nickel Alloy Washers Corrosion Data

- Nickel Alloy 200/201 Fasteners Price List in India

- Frequently Asked Questions

Nickel Alloy Fasteners Specification

| Specifications | Details |

|---|---|

| Nickel Alloy Fasteners Standard | IS, ANSI, ASTM DIN, ISO, JIS, GB, ASME, BS, UNI and all International Standards |

| Threads | BSF, UNF, METRIC, UNC, BSW or as required |

| Nickel Alloy Fasteners Standard | ANSI – American National Standards Institute |

| Stud Bolt Standards | Length defined as per ASME B16.5, ANSI B 28.2.4 1M, ANSI B 18.2.4 2M, ASME B18.5 |

| Hex Nut Standard | ASME B18.2.2 |

| DIN Standards | DIN 933, DIN 931, DIN 970, DIN 934 |

| UTS – Unified Thread Standard | UNF, NPT, NPTF, UNS, UNC, UNEF |

| ISO Standards | ISO 4033, ISO 4032, JIS standards |

| Fasteners / Bolts Size | M10, M4, M16, M36, M2.5, M6, M30, M12, M8, M14, M2, M3, M20, M24, M5 to M160 |

| Length | 3 mm to 200 mm |

| Head Drive | Phillips, Slotted, Phillips/Slot, Six-Lobe etc |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Finishing | Zinc white (yellow, black, blue), black oxide, Dacroment, Geometry, plated zinc-nickel, anodizing, nickel plated, Stainless steel: Passivated, Self-Colour, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, Stainless Steel, DACROMET, Mechanically Applied coating |

| Raw Materials Source | JSPL, Usha Martin, Tata Steel, Mukund Steel, RINL, Dhamm Steel etc. |

| Form | Square, Hex, Threading as per Gauge, Round Etc. |

| Process of Production | M2-M24: Cold Forging, M24-M100: Hot Forging, Machining and CNC for Customized connecting elements |

| Surface Coating |

Xylon Coated Fasteners, Phosphate Coated Fasteners, Hot Dipped Galvanizing Coated Fasteners, Teflon Coated Fasteners, Zinc Coated Fasteners, Cadmium Coated Fasteners, Ptfe Coated Stainless Steel Fasteners |

| Packing | IN BULK: pallet, cartON, carton / Small Boxes / pallet or as per customer request |

Send Your Enquiry

Types Of Nickel Alloy Fasteners

Familiarity with the various types of nickel alloy fasteners enables buyers to choose the right fastener for specific environments and applications. Each fastener type offers unique features suited to corrosion-resistant and high-performance requirements.

Nickel Alloy 200 / 201 Bolts

Nickel Alloy 200 / 201 Bolts

Nickel 200 Structural Bolts ASTM B160

Alloy 201 Heavy Hex Bolts UNS N02200

High-Performance Nickel 200 Hex Bolts

Nickel Alloy 201 Hexagon Head Bolts

Nickel 200 Machine Bolts

Alloy 201 T Bolts

Nickel 200 Eye Bolt

Nickel 201 Foundation Bolts UNS N06601

Nickel Alloy 200 J Bolts

Alloy 201 Button Head Bolt

S32205 Anchor Bolts

Alloy F5 Long Bolts

Nickel 200 Carriage Bolt

High-Performance Nickel 201 Elevator Bolt

Nickel 200 Timber Bolts

Alloy 201 Square Bolt

Nickel 200 Metric Bolt

High-Performance Nickel 201 Plow Bolts DIN 976

Nickel 200 U Bolts DIN 931

Nickel Alloy 201 Flange Bolts

Nickel Alloy 200 / 201 Nuts

Nickel Alloy 200 / 201 Nuts

Nickel 200 T-Slot Nut ASTM B160

Alloy 201 Thin Nuts UNS N02200

High-Performance Nickel 200 Wing Nuts DIN 315

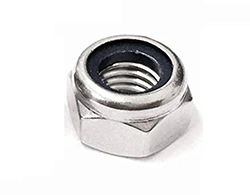

Nickel Alloy 201 Nylon Lock Nut ISO 4032

Nickel 200 Cap Nuts DIN 1587

Alloy 201 Square Nuts

Nickel 200 Coupling Nuts ASTM B162

Alloy 201 Hex Jam Nuts

Nickel Alloy 200 T-Nuts

Nickel 200 Auto Lock Nuts

Alloy 201 Heavy Hex Nut ASTM B564

High-Performance Nickel 200 Miscellaneous Nut

Nickel 200 Nylon Insert Lock Nuts

Alloy 201 Serrated Flange Nuts DIN 6923

Nickel 200 Hexagonal Nuts

High-Performance Nickel 201 Panel Nuts

Nickel 200 Flex Lock Nuts

Alloy 201 Pin Lock Nuts

Nickel 200 Lug Nuts

Nickel Alloy 200 Eye Nuts UNS N06601

Nickel 200 High Tensile Nuts ASTM B160

Alloy 201 Cage Nuts

Nickel 200 Dome Nuts

High-Performance Nickel 200 Knurled Nuts

Nickel 200 Keps-K Lock Nuts

Alloy 201 Machine Hex Nut

Nickel 200 Slotted Nuts DIN 934

Nickel 200 Lifting Eye Nuts

Alloy 201 Sleeve Nuts

Nickel 200 Imperial Nuts

Nickel 200 Rivet Nuts

Alloy 201 Castle Nuts

Nickel 200 Weld Nuts

Nickel 200 ACME Nuts

Nickel 200 High Nuts

Alloy 201 Hex Jam Nuts

Nickel 200 / 201 Washers

Nickel 200 / 201 Washers

Nickel 200 Dome Washers ASTM B160

Alloy 201 Hex Washers DIN 125

Nickel 200 Tab Washers DIN 93

Nickel Alloy 201 Conical Washers ISO 7089

Nickel 200 Lock Washer DIN 127

Alloy 201 Cup Washers

Nickel 200 Belleville Washers ASTM B162

Nickel 201 Wave Washers

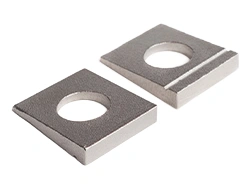

High-Performance Nickel 200 Bevel Washers

Alloy 201 Bonded Sealing Washer

Nickel 200 Hexagon Washer

Alloy 201 Machine Washer

Nickel 200 Dock Washers UNS N02200

Nickel 200 Split Lock Washers DIN 6798

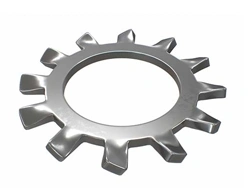

Alloy 201 Tooth Washer

Nickel 200 C Washers

Nickel Alloy 201 Finishing Washers

Nickel 200 Hillside Washers

Alloy 201 Spherical Washers

Nickel 200 Taper Washers

Nickel Alloy 200 Serrated Washers ASTM B564

Alloy 201 Split Washers

Nickel 200 Square Beveled Washers

Ni 200 Curved Spring Washers

Alloy 201 Dome Spring Washers

Nickel 200 Internal Tooth Lock Washer DIN 7980

Alloy 201 Wave Spring Washers

Nickel 200 Split Ring Washers

Ni 200 Star Lock Washer DIN 6798

Nickel Alloy 200 External Tooth Lock Washer

Nickel 200 Hexagonal Washer

Alloy 201 Slotted Washers UNS N06601

Nickel 200 / 201 Stud Bolts

Nickel 200 / 201 Stud Bolts

Nickel Alloy 200 / 201 Studs ASTM B160

Nickel 200 Threaded Stud Bolts DIN 975

Alloy 201 Continuous Thread Stud Bolt ASTM B166

Nickel 200 Partial Threaded Stud Bolt ISO 898-1

Alloy F5 Reduced Shank Stud Bolt

Nickel Alloy S32205 Heavy Stud Bolt ASTM B564

Nickel 200 Industrial Studs

Alloy 201 Flush Head Studs

Nickel 200 Threaded Rods DIN 976

Ni 200 Double Ended Threaded Stud

Alloy 201 Single Ended Threaded Stud

Nickel 200 All Threaded Stud Bolts

Alloy UNS N06601 Metric Thread Stud Bolt

Equivalent Grade of Nickel Screws

Knowing the equivalent grades helps buyers ensure precise material compatibility and compliance with international standards. This aids in selecting the right nickel steel square bolts that match required mechanical and chemical properties for their projects.

| UNS | WNR | ASTM | ASME | JIS | BS | GOST | AFNOR | EN | DIN | |

|---|---|---|---|---|---|---|---|---|---|---|

| Grade | North America | Russia | America | Australia | Japan | United Kingdom | Russia | France | Europe | Germany |

| Nickel 200 | N02200 | 2.4066 | ASTM F2281 | ASME SF 2281 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 | 2.4066 |

| Nickel 201 | N02201 | 2.4068 | ASTM F2281 | ASME SF 2281 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 | 2.4068 |

Physical Properties of UNS N02200 Fasteners

| Physical Property | Value |

|---|---|

| Density | 8.902 gm/cc |

| Melting Point | 1453 °C |

| Boiling Point | 2732 °C |

| Thermal Conductivity | 0.909 W/cm/K @ 298.2K |

| Electrical Resistivity | 6.84 microhm-cm @ 20°C |

| Electronegativity | 1.8 Paulings |

| Specific Heat | 0.106 Cal/g/K @ 25°C |

| Heat of Vaporization | 91.0 K-Cal/g atom at 2732 °C |

| Heat of Fusion | 4.20 Cal/g mole |

Nickel Alloy Hex Bolts Mechanical Properties

Mechanical properties inform buyers about strength, yield, and durability, allowing them to choose nickel alloy hex bolts suitable for high-stress applications. This ensures structural integrity and long-term performance.

| Grades | Properties | Metric | Imperial |

|---|---|---|---|

| Nickel alloy 200 | Tensile strength | 462 MPa | 67000 psi |

| Nickel alloy 200 | Elongation | 45% | 45% |

| Nickel alloy 200 | Yield strength | 148 MPa | 21500 psi |

| Nickel alloy 201 | Tensile strength | 403 MPa | 58500 psi |

| Nickel alloy 201 | Elongation | 50% | 50% |

| Nickel alloy 201 | Yield strength | 103 MPa | 14900 psi |

Corrosion Resistance Of Nickel Screws

Insight into corrosion resistance guides buyers in selecting fasteners that withstand harsh chemicals and saltwater, minimizing maintenance and extending the service life of nickel hex bolts in demanding industries.

| Corrosion Rate (mm/a) | Corrosion Rate (mpy) |

|---|---|

| 0.0056 | 0.222 |

| 0.0036 | 0.144 |

| 0.0002 | 0.0085 |

| 0.00004 | 0.0015 |

Pure Nickel Bolt Torque Chart

Torque charts provide buyers with essential tightening specifications to avoid fastener failure and ensure proper clamping force. This is key for assembly safety and efficiency.

| Bolt Size | Clamp Load (lbs) | Proof Load (lbs) |

|---|---|---|

| 1/4" | 1,313 | 1,750 |

| 5/16" | 2,175 | 2,900 |

| 3/8" | 3,188 | 4,250 |

| 7/16" | 4,388 | 5,850 |

| 1/2" | 5,850 | 7,800 |

| 9/16" | 7,500 | 10,000 |

| 5/8" | 9,300 | 12,400 |

| 3/4" | 13,800 | 18,400 |

| 7/8" | 11,400 | 15,200 |

| 1" | 15,000 | 20,000 |

| 1-1/8" | 18,900 | 25,200 |

| 1-1/4" | 24,000 | 32,000 |

| 1-3/8" | 28,575 | 38,100 |

| 1-1/2" | 34,800 | 46,400 |

Size Chart for Nickel Alloy Fasteners

Size charts assist buyers in selecting the correct dimensions for their nickel alloy fasteners, ensuring compatibility and optimal fit for various industrial applications.

| SIZE | GRADE | ASME | ISO | ASTM |

|---|---|---|---|---|

| M3 to M10 | 012.9 | F835M | ||

| M1.6 to M64 | 12.9 | B18.3.1 M | 4762 | A574M |

| M4 to M20 | 10.9 | |||

| M6 to M24 | 012.9 | B18.3.3M | ||

| M3 to M20 | 012.9 | B18.3.5M | 10642 | F835M |

| M3 to M12 | 012.9 | B18.3.4M | 7380 | F835M |

| M3 to M20 | 45H | B18.3.6M | 4029 | F912M |

| M6 to M12 | 45H | B18.3.6M | 4026 | F912M |

| M3 to M20 | 45H | B18.3.6M | 4029 | F912M |

| M3 to M20 | 45H | B18.3.6M | 4028 | F912M |

| M3 to M12 | 45H | B18.3.6M | 4027 | F912M |

| M8 to M22 | – |

Dimension Chart of Pure Nickel Stud Bolt

Dimension details help buyers verify the exact measurements of stud bolts for seamless integration into assemblies, guaranteeing mechanical compatibility and avoiding costly errors.

| NOMINAL SIZE (D) | D (MIN) | D (MAX) | H (MIN) | H (MAX) | F (MIN) | F (MAX) | C (MIN) | C (MAX) |

|---|---|---|---|---|---|---|---|---|

| m10 | 9.78 | 10.00 | 6.17 | 6.63 | 15.73 | 17.00 | 17.77 | 18.48 |

| m14 | 13.73 | 14.00 | 8.51 | 9.09 | 20.67 | 22.00 | 23.35 | 24.25 |

| m20 | 19.67 | 20.00 | 12.12 | 12.88 | 29.16 | 30.00 | 32.95 | 34.64 |

| m24 | 23.67 | 24.00 | 14.56 | 15.44 | 35.00 | 36.00 | 39.55 | 41.57 |

| m36 | 35.61 | 36.00 | 21.63 | 23.38 | 53.80 | 55.00 | 60.79 | 63.51 |

| m42 | 41.38 | 42.00 | 25.03 | 26.97 | 62.90 | 65.00 | 71.71 | 75.06 |

| m56 | 55.26 | 56.00 | 33.80 | 36.2 | 82.20 | 85.00 | 93.71 | 98.15 |

| m64 | 63.26 | 64.00 | 38.68 | 41.32 | 91.80 | 95.00 | 104.65 | 109.70 |

| m80 | 79.26 | 80.00 | 48.42 | 51.58 | 111.00 | 115.00 | 126.54 | 132.72 |

| m100 | 99.13 | 90.00 | 60.10 | 63.9 | 140.00 | 145.00 | 159.60 | 167.43 |

Nickel Alloy Washers Corrosion Data

| Property | Values | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Media | 1% HCI | 2% H2SO4 | 10% HCI | 5% H2SO4 | 10% CH3CO2H | 19% H2SO4 | 5% H2SO4 with Air | 10% HCI | 10% H3PO4 | 10% HNO3 | 5% CH3CO2H with Air | 10% H3PO4 | 56% CH3CO2H |

| Temperature °F (°C) | 214 (101) | 70 (21) | 86 (30) | 140 (60) | 86 (30) | 223 (106) | 86 (30) | 221 (105) | 75 (24) | 216 (102) | 70 (21) | 214 (101) | 176 (80) |

| Corrosion Rate | 680 | 2 | 80 | 10 | 3.4 | 110 | 61 | 8,000 | 0.6 | 12,000 | 40 | 154 | 66 |

| Common Name | Hydrochloric Acid | Sulfuric Acid | Hydrochloric Acid | Sulfuric Acid | Acetic Acid | Sulfuric Acid | Sulfuric Acid | Hydrochloric Acid | Phosphoric Acid | Nitric Acid | Acetic Acid | Phosphoric Acid | Acetic Acid |

| Media | 85% CH3CO2H with Air | 50% NaOH | 98% CH3CO2H | 50% NaOH | 93% H2SO4 with Air | 90% CH2O2 | 75% NaOH | 90% CH2O2 | 500 ppm NaCIO | 40% H3PO4 | 50% H2SO4 with Air | 20% H2SO4 | 50% H2SO4 |

| Temperature °F (°C) | 70 (21) | 195 (90) | 241 (116) | 310 (155) | 86 (30) | 70 (21) | 250 (120) | 70 (21) | 77 (25) | 75 (24) | 86 (30) | 70 (21) | 255 (124) |

| Corrosion Rate | 400 | 0.55 | 12 | 0.5 | 10 | 4 | 1 | 7 | 0.8 | 1 | 16 | 4 | 1,000 |

| Common Name | Acetic Acid | Caustic Soda | Acetic Acid | Caustic Soda | Sulfuric Acid | Formic Acid (liquid) | Caustic Soda | Formic Acid (vapor) | Sodium Hypochlorite | Phosphoric Acid | Sulfuric Acid | Sulfuric Acid | Sulfuric Acid |

Nickel Alloy 200/201 Fasteners Price List in India

Price lists empower buyers to budget effectively and compare suppliers, balancing cost with quality for nickel alloy 200/201 fasteners in India.

| Description | Price |

|---|---|

| ASTM B160 Nickel 201 Bolt | US $44 - $50 / Kg |

| Werkstoff Nr 2.4068 Nut | US $46 - $47 / Kg |

| UNS N02201 Fasteners | US $44 - $46 / Kg |

| JIS NW 2201 Screw | US $47 - $50 / Kg |

| Werkstoff Nr 2.4068 Washer | US $45 - $49 / Kg |

Frequently Asked Questions About Nickel Alloy 200 / 201 Fasteners

Who is the manufacturer of nickel alloy fasteners in India?

Unifit Fastener is a leading manufacturer of high-quality nickel alloy fasteners in India. Specializing in nickel 200 fasteners, bolts, nuts, and screws, Unifit Metalloys ensures compliance with international ASTM and ASME standards, delivering reliable solutions for demanding industrial applications.

What is a nickel screw?

A nickel screw is a fastening component made from pure nickel or nickel alloys known for corrosion resistance, high strength, and durability. Nickel screws are commonly used in harsh environments like chemical processing and marine industries.

Do nickel bolts rust?

Nickel bolts do not rust like iron; instead, they form a protective oxide layer that prevents rust. Though nickel can corrode in harsh acidic or humid conditions, its corrosion resistance is significantly higher than many other metals.

Is nickel as good as stainless steel?

Nickel offers superior corrosion resistance and electrical conductivity compared to stainless steel, but stainless steel generally has higher strength and better abrasion resistance. Each has distinct advantages depending on the application.

Are screws made of nickel?

Yes, screws can be made from pure nickel or nickel alloys for enhanced corrosion resistance and strength in industrial applications. Nickel plating on screws is also common to improve surface durability and appearance.