At Unifit Metalloys, ASTM A193 Grade B8M fasteners are crafted for environments where standard solutions are not enough. Made from high‑quality 316/316L stainless steel, B8M fasteners are the reliable choice when operations face aggressive chemicals, saltwater, or extreme temperature variations.

B8M fasteners outperform in sectors like chemical processing, marine infrastructure, and water treatment, where corrosion resistance is vital. These components maintain mechanical strength and system integrity, safeguarding pipelines, pressure vessels, and structural builds against pitting and chemical attack.

For mission‑critical projects requiring long‑term durability and unwavering reliability, Grade B8M fasteners deliver dependable performance, helping facilities operate safely and efficiently day after day.

Request QuoteASTM A193 Grade B8M Specification

Understanding the official specification helps buyers select fasteners that meet exact performance standards for high‑stress applications.

ASTM A193 Grade B8M Specification covers the standards for 316/316L stainless steel fasteners designed for high-tensile strength, suitable for high-temperature, high-pressure, and specialized applications. This specification outlines the chemical composition, mechanical properties, heat treatment practices, hardness limits, marking protocols, and certification requirements essential for pressure vessel, valve, flange, and fitting bolting materials.

The fasteners are classified into two property classes: Class 1, featuring carbide solution-treated 316 stainless steel with a minimum tensile strength of 75 ksi (515 MPa), yield strength of 30 ksi (205 MPa), and maximum hardness of 223 HBW (96 HRB); and Class 2, which offers higher mechanical properties with tensile strength of 125 ksi (860 MPa), yield strength of 100 ksi (690 MPa), and maximum hardness up to 321 HBW (35 HRC). This specification supports both metric and imperial unit system requirements.

Comprehensive details on ASTM A193 Grade B8M chemical composition, mechanical strengths, marking standards, and corresponding product references help buyers ensure compliance and suitability for critical industrial uses.

Send Your Enquiry

ASTM A193 Grade B8M Chemical Composition

Understanding the chemical makeup helps buyers assess the fastener’s suitability for applications exposed to aggressive chemicals and extreme conditions.

| Property Class | C | Mn | Si | P | S | Cr | Ni | Mo | V | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| B8M C1 | 0.08 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 10.00 - 14.00 | 2.00 - 3.00 | - | - |

Heat Treatment of ASTM A193 Grade B8M (Class 1 & Class 2)

Heat treatment details are crucial for buyers to select the right grade that delivers the required strength and durability for high-pressure and high-temperature uses.

| Class | Heat Treatment Procedure |

|---|---|

| Class 1 | Carbide Solution Treatment |

| Class 2 | Carbide Solution Treatment & Strain Hardened |

Mechanical Properties for Metric ASTM A193 Grade B8M

Metric mechanical property data enables buyers to verify that fasteners comply with design specifications for safety and performance.

| Class, Diameter In | Heat Treatment | Tensile Strength, min, ksi | Yield Strength, min, 0.2% offset, ksi | Elongation in 4D, min % | Reduction of Area, min % | Hardness, max |

|---|---|---|---|---|---|---|

| B8M C1 | Carbide Solution Treated | 75 | 30 | 30 | 50 | 223 HBW or 96 HRB |

| Class | Diameter Inch | Tensile Strength, min, ksi | Yield Strength, min, 0.2% offset, ksi | Elongation in 4D, min % | Reduction of Area, min % | Hardness, max |

|---|---|---|---|---|---|---|

| Class 2 | M20 and under | 780 | 655 | 15 | 45 | 321 HBW or 35 HRC |

| Over M20 to M24 | 680 | 550 | 20 | 45 | 321 HBW or 35 HRC | |

| Over M24 to M30 | 655 | 450 | 25 | 45 | 321 HBW or 35 HRC | |

| Over M30 to M36 | 620 | 345 | 30 | 45 | 321 HBW or 35 HRC |

ASTM A193 Grade B8M Bolt Marking

Correct bolt markings guarantee authenticity, helping buyers avoid substitution and maintain system integrity.

| Class | Marking Description |

|---|---|

| Class 1 | Manufacturer’s logo (e.g., "BPF") + "B8M" grade |

| Class 2 | Manufacturer’s logo + "B8MSH" indicating strain hardened Class 2 |

Types of ASTM A193 Grade B8M Fasteners

Identifying different fastener types allows buyers to pick the exact products tailored to their unique industrial application needs.

ASTM A193 B8M Bolts

ASTM A193 B8M Structural Bolts

ASTM A193 B8M Heavy Hex Bolts

ASTM A193 B8M Hex Bolts

ASTM A193 B8M Hexagon Head Bolts

SA 193 B8M Machine Bolts

ASTM A193 Grade B8M T Bolts

ASTM A193 Gr. B8M Eye Bolt

SA 193 B8M Foundation Bolts

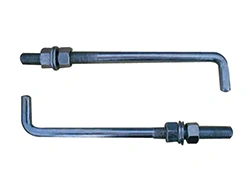

Alloy Steel A193 Gr B8M J Bolts

ASTM A193 B8M Button Head Bolt

SA 193 B8M Anchor Bolts

ASTM A193 B8M Long Bolts

ASTM A193 B8M Carriage Bolt

ASTM A193 B8M Elevator Bolt

ASTM A193 B8M Timber Bolts

SA 193 B8M Square Bolt

ASTM A193 B8M Metric Bolt

ASTM A193 B8M Plow Bolts

Alloy Steel Gr. B8M U Bolts

ASTM A193 B8M Flange Bolts

ASTM A193 B8M Screw (CL 1 & CL2)

ASTM A193 B8M Socket Set Screw

ASTM A193 B8M Self Drilling Screw

ASTM A193 B8M Socket Head Cap Screw

SA 193 B8M Hex Head Screws

ASTM A193 B8M Wood Screw

ASTM A193 Gr. B8M Eye Screw

SA 193 Gr. B8M Wing Screw

ASTM A193 B8M Self Tapping Screws

ASTM A193 Gr. B8M Roofing Screw

ASTM A193 B8M Phillips Head Screw

ASTM A193 B8M Decking Screw

ASTM A193 B8M Machine Screw

ASTM A193 B8M Thumb Screw

ASTM A193 B8M Drywall Screws

SA 193 B8M Chipboard Screw

ASTM A193 B8M Metric Set Screws

Alloy Steel B8M Sems Screw

ASTM A193 B8M Thread Rolling Screw

ASTM A193 B8M Stud Bolt (Class 1 & Class 2)

ASTM A193 B8M Full Threaded Stud Bolts

SA 193 B8M Half Threaded Stud Bolts

Alloy Steel ASTM A193 B8M Threaded Rod

ASTM A193 B8M Double Ended Studs

ASTM A193 B8M Tap End Stud Bolt

Alloy Steel ASTM A193 B8M Tie Rods

Alloy Steel A193 Grade B8M Studs

SA 193 B8M Single End Stud Bolts

A193 Gr.B8M Reduced Shank Stud Bolt

A193 B8M Continuous Threaded Stud Bolt

A193 B8M Partial Threads Stud Bolt

SA193 / A193 B8M Heavy Stud Bolts

ASTM A193 Grade B8M Raw Material

ASTM A193 Grade B8M fasteners are manufactured using high-grade AISI 316/316L stainless steel, fully compliant with the ASTM A193 standard. The bar stock undergoes carbide solution treatment or strain hardening to achieve the required material properties for Class 1 and Class 2 fasteners respectively. Compared to 304 stainless steel, 316 offers superior corrosion resistance, especially against seawater and chloride environments, making it ideal for demanding industrial applications. Certified manufacturers maintain extensive inventories of both annealed and strain-hardened stock to ensure prompt production and faster deliveries of ASTM A193 Grade B8M bolts and screws.

Size Chart of A193 Grade B8M Stud Bolts

Accurate size charts allow buyers to select properly fitting stud bolts, reducing the risk of installation issues and ensuring structural stability.

| Nominal Pipe Size, NPS | Diameter of Bolts, in. | Length of Bolts, L | ||

|---|---|---|---|---|

| Stud Bolts 2mm Raised Face |

Stud Bolts Ring Joint |

Machine Bolts 2mm Raised Face |

||

| 1/2 | 1/2 | 55 | ... | 50 |

| 3/4 | 1/2 | 65 | ... | 50 |

| 1 | 1/2 | 65 | 75 | 55 |

| 1 1/4 | 1/2 | 70 | 85 | 55 |

| 1 1/2 | 1/2 | 70 | 85 | 65 |

| 2 | 5/8 | 85 | 95 | 70 |

| 2 1/2 | 5/8 | 90 | 100 | 75 |

| 3 | 5/8 | 90 | 100 | 75 |

| 3 1/2 | 5/8 | 90 | 100 | 75 |

| 4 | 5/8 | 90 | 100 | 75 |

| 5 | 3/4 | 95 | 110 | 85 |

| 6 | 3/4 | 100 | 115 | 85 |

| 8 | 3/4 | 110 | 120 | 90 |

| 10 | 7/8 | 115 | 125 | 100 |

| 12 | 7/8 | 120 | 135 | 100 |

| 14 | 1 | 135 | 145 | 115 |

| 16 | 1 | 135 | 145 | 115 |

| 18 | 1 1/8 | 145 | 160 | 125 |

| 20 | 1 1/8 | 160 | 170 | 140 |

| 24 | 1 1/4 | 170 | 185 | 150 |

ASTM A193 Grade B8M Torque Chart

Torque charts guide buyers in applying the correct preload, minimizing the risk of under- or over-tightening for safe and effective fastening.

| BOLT DIA | Torque FT-LBS 30% Initial Torque | Torque FT-LBS 70% Torque | Torque FT-LBS 100% Final Torque |

|---|---|---|---|

| 1/2 | 16 | 36 | 52 |

| 9/16 | 23 | 53 | 75 |

| 5/8 | 31 | 73 | 104 |

| 3/4 | 55 | 129 | 184 |

| 7/8 | 71 | 166 | 237 |

| 1 | 107 | 249 | 356 |

| 1.1/8 | 127 | 297 | 424 |

| 1.1/4 | 179 | 417 | 596 |

| 1.3/8 | 186 | 435 | 622 |

| 1.1/2 | 246 | 574 | 821 |

| 1.9/16 | 168 | 392 | 560 |

| 1.5/8 | 191 | 445 | 636 |

| 1.3/4 | 240 | 561 | 801 |

| 1.7/8 | 298 | 696 | 994 |

| 2 | 366 | 853 | 1219 |

| 2.1/4 | 529 | 1234 | 1762 |

| 2.1/2 | 733 | 1709 | 2442 |

| 2.3/4 | 986 | 2300 | 3285 |

| 3 | 1289 | 3008 | 4297 |

Dimensions Chart of ASTM SA193 B8M Heavy Hex Bolt

Knowing precise dimensions is essential for compatibility with flanges, fittings, and assembly requirements in complex projects.

| Nominal Pipe Size, NPS | Diameter of Bolts, in. | Length of Bolts, L (Stud Bolts) | Length of Bolts, L (Machine Bolts) | |

|---|---|---|---|---|

| 2mm Raised Face | Ring Joint | 2mm Raised Face | ||

| 1/2 | 1/2 | 55 | ... | 50 |

| 3/4 | 1/2 | 65 | ... | 50 |

| 1 | 1/2 | 65 | 75 | 55 |

| 1 1/4 | 1/2 | 70 | 85 | 55 |

| 1 1/2 | 1/2 | 70 | 85 | 65 |

| 2 | 5/8 | 85 | 95 | 70 |

| 2 1/2 | 5/8 | 90 | 100 | 75 |

| 3 | 5/8 | 90 | 100 | 75 |

| 3 1/2 | 5/8 | 90 | 100 | 75 |

| 4 | 5/8 | 90 | 100 | 75 |

| 5 | 3/4 | 95 | 110 | 85 |

| 6 | 3/4 | 100 | 115 | 85 |

| 8 | 3/4 | 110 | 120 | 90 |

| 10 | 7/8 | 115 | 125 | 100 |

| 12 | 7/8 | 120 | 135 | 100 |

| 14 | 1 | 135 | 145 | 115 |

| 16 | 1 | 135 | 145 | 115 |

| 18 | 1 1/8 | 145 | 160 | 125 |

| 20 | 1 1/8 | 160 | 170 | 140 |

| 24 | 1 1/4 | 170 | 185 | 150 |

ASTM A193 Grade B8M Anchor Bolts Mechanical Strength

Mechanical strength information allows buyers to choose anchor bolts that will safely support loads and withstand operational stresses.

| Nominal Pipe Size, NPS | Diameter of Bolts, in. | Length of Bolts, L (Stud Bolts) | Length of Bolts, L (Machine Bolts) | |

|---|---|---|---|---|

| 2mm Raised Face | Ring Joint | 2mm Raised Face | ||

| 1/2 | 1/2 | 55 | ... | 50 |

| 3/4 | 1/2 | 65 | ... | 50 |

| 1 | 1/2 | 65 | 75 | 55 |

| 1 1/4 | 1/2 | 70 | 85 | 55 |

| 1 1/2 | 1/2 | 70 | 85 | 65 |

| 2 | 5/8 | 85 | 95 | 70 |

| 2 1/2 | 5/8 | 90 | 100 | 75 |

| 3 | 5/8 | 90 | 100 | 75 |

| 3 1/2 | 5/8 | 90 | 100 | 75 |

| 4 | 5/8 | 90 | 100 | 75 |

| 5 | 3/4 | 95 | 110 | 85 |

| 6 | 3/4 | 100 | 115 | 85 |

| 8 | 3/4 | 110 | 120 | 90 |

| 10 | 7/8 | 115 | 125 | 100 |

| 12 | 7/8 | 120 | 135 | 100 |

| 14 | 1 | 135 | 145 | 115 |

| 16 | 1 | 135 | 145 | 115 |

| 18 | 1 1/8 | 145 | 160 | 125 |

| 20 | 1 1/8 | 160 | 170 | 140 |

| 24 | 1 1/4 | 170 | 185 | 150 |

A193 Grade B8M Stud Bolts Weights

Understanding stud bolt weights supports better logistics, inventory planning, and compliance with equipment load limits.

| Nominal Pipe Size, NPS | Diameter of Bolts, in. | Length of Bolts, L (Stud Bolts) | Length of Bolts, L (Machine Bolts) | |

|---|---|---|---|---|

| 2mm Raised Face | Ring Joint | 2mm Raised Face | ||

| 1/2 | 1/2 | 55 | ... | 50 |

| 3/4 | 1/2 | 65 | ... | 50 |

| 1 | 1/2 | 65 | 75 | 55 |

| 1 1/4 | 1/2 | 70 | 85 | 55 |

| 1 1/2 | 1/2 | 70 | 85 | 65 |

| 2 | 5/8 | 85 | 95 | 70 |

| 2 1/2 | 5/8 | 90 | 100 | 75 |

| 3 | 5/8 | 90 | 100 | 75 |

| 3 1/2 | 5/8 | 90 | 100 | 75 |

| 4 | 5/8 | 90 | 100 | 75 |

| 5 | 3/4 | 95 | 110 | 85 |

| 6 | 3/4 | 100 | 115 | 85 |

| 8 | 3/4 | 110 | 120 | 90 |

| 10 | 7/8 | 115 | 125 | 100 |

| 12 | 7/8 | 120 | 135 | 100 |

| 14 | 1 | 135 | 145 | 115 |

| 16 | 1 | 135 | 145 | 115 |

| 18 | 1 1/8 | 145 | 160 | 125 |

| 20 | 1 1/8 | 160 | 170 | 140 |

| 24 | 1 1/4 | 170 | 185 | 150 |