Unifit Fastener is a trusted supplier and exporter of Stainless Steel 321 Tube Plugs, engineered for secure tube sealing in heat exchangers, condensers, boilers and other high-temperature process equipment. Manufactured from titanium-stabilized austenitic stainless steel, these plugs offer excellent resistance to intergranular corrosion and oxidation up to 900°C making them ideal for thermal cycling applications.

Our SS 321 Tapered Tube Plugs are precisely machined for a tight, leak-proof fit ensuring long service life even in aggressive environments. Available in various diameters, lengths, and taper angles, these tube plugs can be customized to match exact application requirements, guaranteeing optimal performance and easy installation without damaging tube sheets.

Designed and tested to ASTM, ASME and DIN standards, Unifit Fastener’s 321 Stainless Steel Tube Plugs are widely preferred in power plants, petrochemical refineries, marine systems and chemical processing industries where reliability under heat and stress is essential.

Request QuoteWhat are Stainless Steel 321 Tube Plugs?

Stainless Steel 321 Tube Plugs are mechanical components used to seal, isolate, or block damaged or unused tubes in equipment such as heat exchangers and condensers. Unlike temporary sealing methods, tube plugs provide a permanent and maintenance-free solution, preventing fluid leakage and maintaining system efficiency.

The SS 321 grade is specifically selected for tube plugs due to its titanium stabilization, which prevents carbide precipitation during high-temperature exposure. This ensures the plugs maintain their corrosion resistance and mechanical strength even in continuous service at elevated temperatures.

Available in tapered and parallel designs, SS 321 Tapered Tube Plugs offer easy installation by simply driving them into the tube end for a secure seal. The smooth finish and precision tolerances reduce the risk of tube sheet damage while ensuring maximum sealing effectiveness.

Send Your Enquiry

Types of Stainless Steel 321 Tube Plugs

Stainless Steel 321 Tube Plugs are available in various designs to suit different sealing requirements in heat exchangers, boilers, and condensers. The choice of plug type depends on factors like tube size, operating pressure, temperature range and the nature of the media flowing through the system. At Unifit Fastener, we offer a range of precision-engineered SS 321 tube plugs that ensure leak-proof performance, easy installation, and long service life in demanding environments.

SS 321 Tube Plugs Types

- SS 321 Expandable Tube Plug

- SS 321 Boiler Tapered Tube Plug

- SS 321 Threaded Tapered Tube Plugs

- Steel 321 One-Piece Tube Plugs

- SS 321 Tapered Metal Tube Plugs

- SS 321 Tapered Tube Plugs

- SS 321 Heat Exchanger Tube Plugs

- 321 Stainless Steel Pin Tube Plug

- Stainless Steel 321 Collar Tube Plug

- SS 321 Threaded Tapered Plugs

- SS 321 Condenser Tube Plug

- SS 321 Condenser Tube Plugging

- Stainless Steel 321 Boiler Tube Plugs

- SS 321 Metal Tapered Tube Plug

Stainless Steel 321 Tube Plug Specifications

Stainless Steel 321 Tube Plugs are available in a wide range of standard and custom sizes to suit various tube diameters in heat exchangers, condensers and boilers. Their precise taper and accurate dimensions ensure a secure fit, preventing leakage and maintaining system integrity even under high-temperature and corrosive conditions.

| Standard | ASTM A182, ASME SA182, DIN 1.4541 |

|---|---|

| Material Grade | Stainless Steel 321 (UNS S32100) |

| Designs Available | Tapered, Parallel, Custom |

| Size Range | As per requirement |

| Finish | Smooth Machined / Polished |

| Tolerance | ±0.05 mm or as specified |

Stainless Steel 321 Tube Plugs Equivalent Grades

Stainless Steel 321 Tube Plugs are manufactured to meet various international standards, ensuring compatibility for global industrial applications. These equivalent grades help engineers and procurement teams identify matching specifications across different standards. The table below lists the most common equivalents for SS 321 and SS 321H Tube Plugs:

| Standard | Grade | Description |

|---|---|---|

| UNS | S32100 / S32109 | Titanium-stabilized austenitic stainless steel grades for enhanced resistance to intergranular corrosion. |

| WERKSTOFF NR. | 1.4541 / 1.4878 | German standard designation for SS 321 / 321H. |

| EN | X6CrNiTi18-10 | European standard name for SS 321. |

| JIS | SUS 321 | Japanese Industrial Standard equivalent. |

| BS | 321S31 | British Standard specification. |

| GOST | 08Х18Н10Т | Russian equivalent grade. |

| AFNOR | Z6CNT18-10 | French standard equivalent for SS 321. |

Stainless Steel 321 Tube Plugs Chemical Composition

The chemical composition of Stainless Steel 321 Tube Plugs is carefully balanced to provide strength, corrosion resistance and stability during service. Here's the detailed breakdown:

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Carbon (C) | – | 0.08 |

| Manganese (Mn) | – | 2.00 |

| Silicon (Si) | – | 0.75 |

| Phosphorus (P) | – | 0.045 |

| Sulfur (S) | – | 0.030 |

| Chromium (Cr) | 17.00 | 19.00 |

| Nickel (Ni) | 9.00 | 12.00 |

| Titanium (Ti) | 5 × C min | 0.70 |

| Iron (Fe) | Balance | Balance |

Stainless Steel 321 Tube Plugs Mechanical Properties

The mechanical properties of Stainless Steel 321 Tube Plugs make them a reliable choice for sealing applications in heat exchangers, condensers, and boilers. Below are the mechanical properties:

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength (min) | 515 MPa | 75,000 psi |

| Yield Strength (0.2% Proof, min) | 205 MPa | 30,000 psi |

| Elongation (min) | 40% | 40% |

| Hardness (Brinell, max) | 217 HB | 217 HB |

| Modulus of Elasticity | 193 GPa | 28,000 ksi |

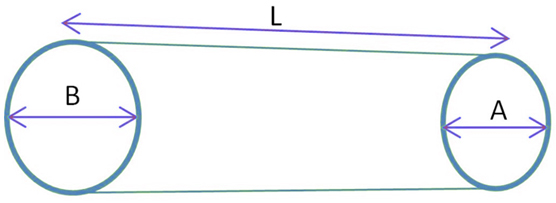

Stainless Steel 321 Tube Plugs Sizes

| Tube OD | Gauge | Dimension (Inches) | ||

|---|---|---|---|---|

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Why Choose Stainless Steel 321 Tube Plugs?

Selecting the right tube plug is critical for maintaining the safety, efficiency, and lifespan of heat exchangers, condensers, and boilers. Stainless Steel 321 Tube Plugs stand out because they combine titanium-stabilized metallurgy with proven high-temperature performance. Unlike standard stainless steels, SS 321 is engineered to resist intergranular corrosion caused by chromium carbide precipitation during prolonged exposure to temperatures between 450°C and 900°C.

When sourced from a reputable manufacturer, each plug undergoes stringent quality control, including dimensional checks, hardness testing, and corrosion resistance evaluation ensuring they meet international standards such as ASTM, ASME and ISO. This ensures end users benefit from longer service life, fewer unplanned shutdowns, and lower total cost of ownership, all backed by material traceability and compliance documentation.

Applications of Stainless Steel 321 Tube Plugs

Engineered for environments where high temperatures and corrosive media are part of daily operations, Stainless Steel 321 Tube Plugs offer a dependable solution for isolating or sealing tubes without compromising system performance. Their titanium-stabilized composition ensures that even in prolonged heat service, the plugs maintain dimensional stability and leak-tight sealing. This makes them a preferred choice in:

- Thermal Power Plants

- Oil Refineries

- Petrochemical Industries

- Marine & Offshore Systems

- Desalination Plants

- Pharmaceutical Industries

- Food & Beverage Processing Units

- Heat Exchangers & Condensers

- Chemical Processing Plants

- Pulp & Paper Mills

Stainless Steel 321 Tube Plugs Price

The cost of Stainless Steel 321 Tube Plugs is influenced by factors such as dimensions, quantity, manufacturing tolerances and any special surface treatments. Custom-made plugs or those meeting stringent industry specifications may have higher pricing due to additional machining and quality checks.

We offer competitive rates by sourcing directly from trusted mills and maintaining efficient production processes. Every order is backed by material test reports (MTRs), traceability, and quality assurance ensuring you get reliable components at the best value for your application.

Trusted Manufacturer & Supplier of Stainless Steel 321 Tube Plugs

As a reliable source for Stainless Steel 321 Tube Plugs, we combine precision engineering with strict quality standards to deliver components that meet demanding industrial needs. Every plug is manufactured from premium-grade SS 321, ensuring excellent heat resistance, corrosion protection, and mechanical strength.

Our production facility follows ISO-compliant processes, from raw material inspection to final dimensional checks, ensuring each plug matches exact specifications. We cater to bulk, urgent, and custom orders across diverse industries such as power generation, petrochemicals, marine and aerospace.

With a strong supply chain network, timely delivery, and technical expertise, we stand as a trusted partner for businesses worldwide looking for consistent quality and dependable service.

Request QuoteFrequently Asked Questions About Stainless Steel 321 Tube Plugs

What is Stainless Steel 321, and why is it used for tube plugs?

Stainless Steel 321 is a titanium-stabilized austenitic stainless steel offering excellent resistance to intergranular corrosion, high-temperature oxidation and stress cracking. This makes it ideal for tube plugs used in heat exchangers, boilers and condensers.

Are SS 321 tube plugs suitable for high-temperature applications?

Yes. SS 321 can withstand temperatures up to 870°C in continuous service and 925°C in intermittent service, making it highly reliable in high-temperature and high-pressure environments.

Do Stainless Steel 321 tube plugs come in standard sizes?

They are available in a wide range of standard and custom sizes to fit various tube diameters and specifications ensuring a perfect sealing solution.

Can I get custom dimensions for SS 321 tube plugs?

Absolutely. We manufacture SS 321 tube plugs in custom sizes and shapes to meet specific industry or equipment requirements.

Which industries use Stainless Steel 321 tube plugs the most?

Common industries include petrochemical plants, power generation, marine applications, food processing and aerospace, anywhere high corrosion resistance and temperature stability are essential.