Inconel Washers Manufacturer, Supplier & Stockist

Unifit Fastener is a reputable manufacturer and supplier of high-quality Inconel washers that have been designed to meet the tough industrial settings. Our washers are a full feature of the machine, such as flat washers and machine screw washers, as well as custom designs based on the international standards, including ASTM, SAE and USS. They are manufactured with the high-performance nickel-chromium alloys like Inconel 600, 601, 625, 718 and X-750, which provide superior mechanical strength and corrosion resistance.

The alloy washers are made of molybdenum, chromium, and nickel, thus allowing them to work under extreme temperature conditions, i.e., cryogenic as well as 982°C (2200°F). They have great thermal withstanding and oxidation resistance and thus can be used in highly corrosive and high-pressure environments. They do not succumb to chloride stress corrosion cracking, pitting and crevice corrosion even in adverse media such as seawater, alkaline solutions and chemical vapours.

Unifit Fastener offers Inconel washers the perfect mix of strength, toughness and durability; hence they are preferable in the aerospace marine, oil and gas, chemical processing, heat exchanger, boiler, power plant, petrochemical, pharmaceutical and food processing industries.

All the batches of washers are subject to ultra-quality examination, such as chemical examination, tensile examination, hardness examination, PMI, IGC examination, pitting examination, and dimensional examination. Our delivery is safe by using sturdy wooden crates or reinforced cartons.

Select Unifit Fastener to get high-performance. Inconel washers that are highly reliable and surpass industrial performance.

Request QuoteTable of Contents

- What Are Inconel Washers?

- Inconel Washer Grades

- Specification of Inconel Washers

- Send Your Enquiry

- Types of Inconel Washers

- Chemical Composition of Inconel Washers

- Mechanical Properties of Inconel Washers

- Equivalent Grades of Inconel Washers

- Inconel Washer Dimension Chart (USS & SAE)

- Applications & Uses of Inconel Washers

- People Ask About Inconel Washers

What Are Inconel Washers?

Inconel washers are superalloy nickel-chromium fasteners that are constructed to offer high strength, resistance to corrosion and stability in extreme temperatures and other difficult chemical conditions that would cause the breakdown of ordinary washers. They are used to share load, stop leakage and keep joints in vital industries such as aerospace, marine, oil and gas and nuclear power resistant to oxidation, acids and chloride stress cracking. Popular grades Inconel 625 washers and Inconel 718 washers come in many forms, such as flat, lock and Belleville washers.

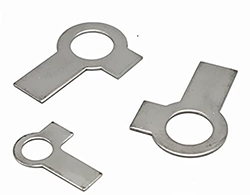

Inconel Conical Washer, ASTM B166 Inconel Machine Washer Stockist, Inconel Alloy Flat Washer, Inconel Wire Spring, Incoloy Slot Washer Suppliers and Exporters, Inconel Star Washer Exporter, Inconel Alloy Sealing Washer, Inconel Flat Spring Manufacturer in India, Inconel Lock Washer, ASTM B166 Inconel Split Washer.

Inconel Washer Grades

Incoloy 800H & 825 Washers

Specification of Inconel Washers

| Parameter | Specification |

|---|---|

| Standard | ASTM / ASME |

| Dimensions | ASTM, DIN, BS, GB, IS & other International Standards |

| Size Range | M02 to M33 |

| Washer Diameter | 3 mm to 200 mm |

| Material Grades | Inconel 600, Inconel 601, Inconel 625, Incoloy 800, Incoloy 800H, Incoloy 800HT |

| Washer Types | Plain Washer, Spring Washer, Tooth Washer, Taper Washer, Tab Washer, Star Washer, and Custom Types |

Send Your Enquiry

Types of Inconel Washers

Inconel Plain Washer

Inconel Spring Washer

Inconel Ogee Washer

Inconel Flat Washer

Inconel Lock Washer

Inconel Tooth Washer

Inconel Taper Washer

Inconel Tab Washer

Inconel Star Washer

Inconel Split Washer

Chemical Composition of Inconel Washers

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 0.15 max | 1.00 | 0.50 | 0.015 | 0.50 | 6.00–10.00 | 72.00 min | 14.00–17.00 |

| Inconel 601 | 0.10 | 1.00 | 0.50 | 0.015 | 1.00 | Balance | 58.0–63.0 | 21.0–25.0 |

| Inconel 625 | 0.10 | 0.50 | 0.50 | 0.015 | – | 5.0 max | 58.0 min | 20.0–23.0 |

| Inconel 718 | 0.08 | 0.35 | 0.35 | 0.015 | 0.30 | – | 50.0–55.0 | 17.0–21.0 |

| Incoloy 825 | 0.05 | 1.00 | 0.50 | 0.03 | 1.5–3.0 | 22.0 min | 38.0–46.0 | 19.5–23.5 |

| Incoloy 800HT | 0.06–0.10 | 1.50 | 1.00 | 0.015 | 0.75 | 39.5 min | 30.0–35.0 | 19.0–23.0 |

Mechanical Properties of Inconel Washers

| Grade | Density | Melting Point | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|---|---|

| Inconel 600 | 8.47 g/cm³ | 1413°C | 655 MPa | 310 MPa | 40% |

| Inconel 601 | 8.10 g/cm³ | 1411°C | 550 MPa | 205 MPa | 30% |

| Inconel 625 | 8.40 g/cm³ | 1350°C | 930 MPa | 517 MPa | 42.5% |

| Inconel 718 | 8.20 g/cm³ | 1350°C | 930 MPa | 482 MPa | 45% |

| Inconel X-750 | – | 1430°C | 1267 MPa | 868 MPa | 25% |

| Incoloy 825 | 8.14 g/cm³ | 1400°C | 550 MPa | 220 MPa | 30% |

| Incoloy 800HT | 7.94 g/cm³ | 1385°C | 520 MPa | 205 MPa | 30% |

| Incoloy 925 | 8.08 g/cm³ | 1311–1366°C | 685 MPa | 271 MPa | 56% |

Equivalent Grades of Inconel Washers

| Grade | Werkstoff Nr. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

| Inconel 718 | 2.4668 | N07718 | – | – | – | – | – |

| Inconel X-750 | 2.4669 | N07750 | – | – | – | – | – |

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | ЭП703 | NFE30C20DUM | NiCr21Mo |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15 (HT) | ЭИ670 | – | X8NiCrAlTi32-21 |

| Incoloy 925 | – | N09925 | NCF 925 | – | – | – | – |

Inconel Washer Dimension Chart (USS & SAE)

| Size | USS ID (A) | USS OD (B) | USS Thk (C) | SAE ID (A) | SAE OD (B) | SAE Thk (C) |

|---|---|---|---|---|---|---|

| #2 | – | – | – | 3/32″ | 1/4″ | 0.020″ |

| #4 | – | – | – | 1/8″ | 5/16″ | 0.032″ |

| #6 | – | – | – | 5/32″ | 3/8″ | 0.049″ |

| #8 | – | – | – | 3/16″ | 7/16″ | 0.049″ |

| #10 | – | – | – | 7/32″ | 1/2″ | 0.049″ |

| #12 | – | – | – | 1/4″ | 9/16″ | 0.065″ |

| 1/4″ | 5/16″ | 0.734″ | 0.065″ | 9/32″ | 5/8″ | 0.065″ |

| 3/8″ | 7/16″ | 1″ | 0.083″ | 13/32″ | 13/16″ | 0.065″ |

| 1/2″ | 9/16″ | 1-3/8″ | 0.109″ | 17/32″ | 1-1/16″ | 0.095″ |

| 5/8″ | 11/16″ | 1-3/4″ | 0.134″ | 21/32″ | 1-5/16″ | 0.095″ |

| 3/4″ | 13/16″ | 2″ | 0.148″ | 13/16″ | 1-15/32″ | 0.134″ |

| 1″ | 1-1/16″ | 2-1/2″ | 0.165″ | 1-1/16″ | 2″ | 0.134″ |

| 1-1/4″ | 1-3/8″ | 3″ | 0.165″ | – | – | – |

| 1-1/2″ | 1-5/8″ | 3-1/2″ | 0.180″ | – | – | – |

| 2″ | 2-1/8″ | 4-1/2″ | 0.213″ | – | – | – |

Inconel Spring Washer Dimensions (Metric)

| Nominal Size | Inner Dia (mm) | Outer Dia (mm) | Width (mm) | Thickness (mm) | Weight / 1000 (kg) |

|---|---|---|---|---|---|

| 3 | 3.1 | 6.2 | 1.3 | 0.8 | 0.11 |

| 5 | 5.1 | 9.2 | 1.8 | 1.2 | 0.36 |

| 8 | 8.1 | 14.8 | 3.0 | 2.0 | 1.60 |

| 12 | 12.2 | 21.1 | 4.0 | 2.5 | 3.82 |

| 16 | 16.2 | 27.4 | 5.0 | 3.5 | 8.91 |

| 20 | 20.2 | 33.6 | 6.0 | 4.0 | 15.20 |

| 24 | 24.5 | 40.0 | 7.0 | 5.0 | 26.20 |

| 30 | 30.5 | 48.2 | 8.0 | 6.0 | 44.30 |

| 36 | 36.5 | 58.2 | 10.0 | 6.0 | 67.30 |

| 42 | 42.5 | 68.2 | 12.0 | 7.0 | 111.00 |

| 52 | 53.0 | 83.0 | 14.0 | 8.0 | 320.00 |

International Standards for Inconel Washers

| Standard | Description |

|---|---|

| AS 1237.1-2002 | Plain & Small Plain Washers |

| ASTM F436 / F436M | Heavy & Clipped Structural Washers |

| ANSI B18.2.6 | Circular & Clipped Washers |

| ANSI B18.22.1 Type A & B | Plain Washers |

| DIN 125-2 | Type A & Type B Washers |

Inconel Washer Weight Chart (Metric Sizes)

| Size | Plain Punched (IS 2016) | Heavy Washer (IS 6610) | Machined Washer (IS 2016) | Square / Taper Washer | Spring Washer – Flat (IS 3063) | Spring Washer – Square (IS 6735) |

|---|---|---|---|---|---|---|

| M3 | – | – | – | – | 0.01 | 0.01 |

| M4 | – | – | – | – | 0.02 | 0.02 |

| M5 | 0.04 | – | 0.04 | – | 0.03 | 0.03 |

| M6 | 0.11 | – | 0.11 | – | 0.08 | 0.04 |

| M8 | 0.20 | – | 0.21 | 1.10 | 0.16 | 0.11 |

| M10 | 0.39 | 1.60 | 0.40 | 1.00 | 0.25 | 0.20 |

| M12 | 0.58 | 1.90 | 0.62 | 2.00 | 0.38 | 0.23 |

| M14 | 0.82 | – | – | – | 0.60 | 0.38 |

| M16 | 1.06 | 2.90 | 1.13 | 3.40 | 0.89 | 0.59 |

| M18 | 1.27 | – | – | – | 0.97 | 0.66 |

| M20 | 1.64 | 4.40 | 1.72 | 5.80 | 1.52 | 1.23 |

| M22 | 1.75 | – | – | – | 1.65 | 1.36 |

| M24 | 3.11 | 6.30 | 3.30 | 13.50 | 2.62 | 1.81 |

| M27 | 3.94 | 8.00 | 4.23 | 12.50 | 2.87 | 2.06 |

| M30 | 5.05 | 10.10 | 5.36 | 16.50 | 4.43 | 3.20 |

| M33 | 7.10 | 12.00 | 7.54 | 21.00 | 6.30 | 3.50 |

| M36 | 8.73 | 14.60 | 9.20 | 25.50 | 6.73 | 5.25 |

| M39 | 12.60 | 16.70 | 13.30 | 28.30 | 7.17 | 5.61 |

| M42 | 17.50 | 20.10 | 18.30 | – | 11.10 | 8.00 |

| M45 | 21.20 | 22.20 | 22.00 | – | 11.70 | 8.53 |

| M48 | 28.40 | 26.00 | 29.40 | – | 12.30 | 9.00 |

| M52 | 31.90 | – | 33.00 | – | 18.20 | – |

| M56 | 47.90 | – | – | – | 19.30 | – |

| M60 | 51.60 | – | – | – | 20.30 | – |

| M64 | 55.40 | – | – | – | 21.80 | – |

| M72 | 63.40 | – | – | – | 24.00 | – |

Inconel Washer Inch Size Reference (Plain Punched Washers)

| Size (Inches) | Weight per 100 Nos (kg) |

|---|---|

| 1/4″ | 0.21 |

| 5/16″ | 0.35 |

| 3/8″ | 0.48 |

| 1/2″ | 1.07 |

| 5/8″ | 1.85 |

| 3/4″ | 2.91 |

| 7/8″ | 4.27 |

| 1″ | 6.13 |

| 1 1/8″ | 7.69 |

| 1 1/4″ | 9.90 |

| 1 1/2″ | 17.24 |

| 2″ | 27.78 |

Ready Stock of Inconel Washers

| Inconel Flat Washers Manufacturer | Inconel Machine Washers |

| Incoloy Washer Price | Inconel Ogee Washer |

| Incoloy Alloy Tab Washers | Inconel Dome Washer |

| Incoloy Washer Supplier in India | Inconel® Alloy Lock Washer |

| Inconel Spherical Washers | Incoloy Belleville Washer |

| Inconel Metric Washers | Incoloy Plain Washers |

| Inconel 3 Inch Flat Washer | Inconel Star Washer |

| Incoloy® Alloy Washer Stocks | Incoloy Countersunk Finishing Washer |

| Inconel Washers At Best Price in India | Inconel Washer Stockholder |

| Inconel Flat Penny Washers | Inconel Alloy Washer Manufacturer in Mumbai |

| Incoloy Fender Washer | Inconel Cup Washer |

Applications & Uses of Inconel Washers

- Oil & Gas refineries

- Petrochemical plants

- Heat exchangers & boilers

- Power generation units

- Marine & offshore platforms

- Aerospace & aviation components

- Chemical processing equipment

- Pharmaceutical & food processing plants

- Condensers, turbines & pumps

People Ask About Inconel Washers

What is an Inconel washer?

An Inconel washer is manufactured from a nickel-chromium alloy engineered to perform in extreme temperatures and highly corrosive environments. It offers high mechanical strength, excellent oxidation resistance, and a long service life in demanding industrial applications.

Which grades of Inconel washers are available at Unifit Fastener?

Unifit Fastener supplies Inconel washers in grades 600, 601, 625, and 718. In addition, Incoloy grades such as 800, 800H, and 800HT are also available to meet high-temperature and pressure requirements.

Can Inconel washers withstand high temperatures?

Yes, Inconel washers are capable of operating at temperatures up to 982°C (2200°F). This makes them ideal for use in boilers, gas turbines, heat exchangers, furnaces, and other high-temperature equipment.

Are Inconel washers corrosion resistant?

Yes, Inconel washers provide excellent resistance to oxidation, seawater, aggressive chemicals, and chloride-induced stress corrosion cracking, ensuring reliable performance in harsh and corrosive environments.