ASTM A193 Gr B7M Fasteners Suppliers

Unifit Fastener also offers high performance ASTM A193 Gr B7M fasteners, which are optimized to operate in harsh chemical settings especially those that contain nitric acid. They are reliable due to controlled concentrations of carbon, silicon and phosphorus which assist in stabilising the austenitic structure and inhibiting the formation of carbide or other inter metallic compounds. This makes sure that fasteners will be able to withstand aggressive conditions in terms of structural strength.

B7M bolts, studs, nuts and screws are heat treated to provide consistent mechanical properties that are required at high temperatures and pressure. The specification limits hardness to 99 HRB, tensile strength of 100 ksi minimum and yield strength of 75 ksi, providing a reliable performance not possible with standard alloy fasteners.

Nevertheless, such fasteners are contraindicated with concentrated nitric acid that includes CrVI as it will result in the material degradation. Beyond this constraint, B7M products have good ductility and weldability and can be useful in oil refineries, petrochemical plants, water treatment plants and chemical processing facilities.

In the case of ASTM A193 Grade B7M washers, pickling is usually conducted by either dipping, spraying or placing some pickling paste, depending on the facility process. High-velocity oxy-fuel coating tests demonstrated that B7M hex head bolts exhibit greater wear resistance in high temperatures and can offer enhanced lifetimes in corrosive and abrasive environments.

They are usually made out of alloy steel AISI 4140/4142, quenched and tempered to enhance their dimensional stability, resist corrosion, and durability with time. They are balanced and controlled hard, thus making them a good choice when vital industrial use is required.

Request QuoteTable of Contents

- What is ASTM A193 Grade B7M Fasteners?

- Send Your Enquiry

- ASTM A193 Gr B7M Fasteners Specification

- Chemical Composition

- Heat Treatment

- Mechanical Properties (Metric)

- Types of B7M Fasteners

- Raw Material Chart

- Stud Bolt Size Chart

- Torque Chart

- Hex Bolt Dimensions (Metric)

- Stud Bolt Dimensions (Metric)

- Hex Nut Dimensions (Metric)

- Washer Dimensions

- Stud Bolt Weight Chart

- Applications

- Manufacturers / Suppliers / Exporters

- Frequently Asked Questions

Send Your Enquiry

Specification ASTM A193 Gr B7M Fasteners

With the understanding of the ASTM A193 Gr B7M fastener specification, the buyer can be assured that he or she is procuring fasteners of the high standard that is needed when it comes to use in specific industrial applications. This understanding ensures conformity and security.

| ASME SA 193 Grade B7m Bolts | ANSI B18.2.1, DIN 931/ 933 |

|---|---|

| ASTM A193 Grade B7m Hex Bolts Size Metric | Dia: M10 - M110 Length: 12 - 1200MM |

| SA 193 Grade B7m Hex Bolts Size Inch | Dia: 1/2" - 4.0" Length: 1/2" - 52" |

| ASTM A193 gr B7m Eye Bolts Metric Size | Dia: M10 - M48 |

| A193 Gr B7m Stud Bolt Metric Size | Dia: M10 - M110 Length: 12 mm - 6000 mm |

| ASTM A193 B7m Stud Bolt Inch | Dia: 1/2" - 4.1/2" Length: 1/2" - 236" |

| A193 Grade B7m Hex Nut (DIA) | Metric: M6 - M110 Inch: 1/4" - 4.5" |

| SA 193 B7m Plain Washer (DIA) | Metric: M6 - M110 Inch: 1/2" - 4.1/2" |

| ASTM A193 Grade B7m Bolts International Standard | IS, ANSI, ASTM DIN, ISO, JIS, GB, ASME, BS, UNI |

| A193 B7m Bolts Standard Sizes | M10, M4, M16, M36 M2.5, M6, M30, M12, M8, M14, M2, M3, M20, M24, M5 to M160 |

| ASME SA 193 B7m Fasteners Threads | BSF, UNF METRIC, UNC, UNEF, BSW or as required |

| ASME/ ANSI - American Standard ASTM A193 Grade B7m Bolts | ANSI B 28.2.4 1M ANSI B 18.2.4 2M ASME B18.5 ASME B18.2.2 |

| DIN German Standard ASTM A193 Grade B7m Bolts | DIN 933, DIN 931, DIN 970, DIN 934 |

| ISO Standard ASTM A193 B7m Alloy Steel Bolts | ISO 4033, ISO 4032, JIS standards |

| A193 B7m Alloy Steel Bolts / Screws Head Drive | Phillips, Slotted, Phillips/Slot, Six-Lobe |

| MTC (Manufacturer Test Certificate) | EN 10204 / 3.1 |

| ASME SA 193 Gr B7m Nut Bolt Finishing |

Zinc white, (yellow, black, blue), black oxide, Dacroment, Geometry, plated zinc-nickel, anodizing, nickel plated, Stainless steel: Passivated Self-Colour, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, DACROMET and Mechanically Applied coating |

| SA 193 Gr B7m Fasteners Production Process | M2-M24: Cold Forging, hot forging M24-M100, machining and CNC for Customized connecting element |

| ASTM A193 Grade B7m Bolts Coating |

Xylon Coated Fasteners Phosphate Coated Fasteners Hot Dipped Galvanizing Coated Fasteners Teflon Coated Fasteners Zinc Coated Fasteners Cadmium Coated Fasteners Ptfe Coated (Teflon) Fasteners |

| ASTM A193 Grade B7m Alloy Steel Fasteners Packing | Wooden Pallet, Canton, Carton / Small Box or as required |

Chemical Composition ASTM A193 Gr B7M Fasteners

Chemical composition of the ASTM A193 Gr B7M fasteners would be useful in evaluating the behaviour of the materials in aggressive chemical environments. The knowledge will help in choosing appropriate fasteners to be used in sensitive locations.

| B7M | C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| B7M | 0.37 - 0.49 | 0.65 - 1.10 | 0.035 Max | 0.04 Max | 0.15 - 0.35 | 0.75 - 1.20 | 0.15 - 0.25 |

Heat Treatment of ASTM A193 Grade B7M Fasteners

This is explained by the knowledge of the heat treatment procedures of the ASTM A193 Grade B7M fasteners, which help in attaining their mechanical properties. This guarantees buyers that the fasteners can endure rigorous service conditions.

| Heat Treatment Condition |

|---|

| Hardened @850°C & Tempered @650°C |

Mechanical Properties for Metric ASTM A193 Grade B7M Fasteners

Interested buyers should review the mechanical properties specific to metric ASTM A193 Grade B7M fasteners to confirm suitability for exact application requirements internationally.

| Grade | Description | Diameter | Tensile Strength, min. | Yield Strength, min. | Hardness, max. | Marking |

|---|---|---|---|---|---|---|

| ASTM A193 B7M | Chromium-Molybdenum | 4″ and under | 100 | 80 | 235 HB or 99 HRB | B7M |

| ASTM A193 B7M | Chromium-Molybdenum | over 4″ to 7″ | 100 | 75 | 235 HB or 99 HRB | B7M |

Types of ASTM A193 Grade B7M Fasteners

Awareness of the various ASTM A193 Grade B7M fastener types available helps buyers make informed choices tailored to their project needs and operating conditions.

ASTM A193 B7M Structural Bolts

ASTM A193 B7M Heavy Hex Bolts

ASTM A193 B7M Hex Bolts

ASTM A193 B7M Hexagon Head Bolts

SA 193 B7M Machine Bolts

ASTM A193 Grade B7M T Bolts

ASTM A193 Gr. B7M Eye Bolt

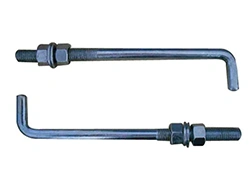

SA 193 B7M Foundation Bolts

Alloy Steel A193 Gr B7M J Bolts

ASTM A193 B7M Button Head Bolt

SA 193 B7M Anchor Bolts

ASTM A193 B7M Long Bolts

ASTM A193 B7M Carriage Bolt

ASTM A193 B7M Elevator Bolt

ASTM A193 B7M Timber Bolts

SA 193 B7M Square Bolt

ASTM A193 B7M Metric Bolt

ASTM A193 B7M Plow Bolts

Alloy Steel Gr. B7M U Bolts

ASTM A193 B7M Flange Bolts

ASTM A193 B7M Socket Set Screw

ASTM A193 B7M Self Drilling Screw

ASTM A193 B7M Socket Head Cap Screw

SA 193 B7M Hex Head Screws

ASTM A193 B7M Wood Screw

ASTM A193 Gr. B7M Eye Screw

SA 193 Gr. B7M Wing Screw

ASTM A193 B7M Self Tapping Screws

ASTM A193 Gr. B7M Roofing Screw

ASTM A193 B7M Phillips Head Screw

ASTM A193 B7M Decking Screw

ASTM A193 B7M Machine Screw

ASTM A193 B7M Thumb Screw

ASTM A193 B7M Drywall Screws

SA 193 B7M Chipboard Screw

ASTM A193 B7M Metric Set Screws

Alloy Steel B7M Sems Screw

ASTM A193 B7M Thread Rolling Screw

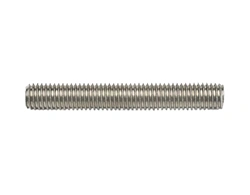

ASTM A193 B7M Full Threaded Stud Bolts

SA 193 B7M Half Threaded Stud Bolts

Alloy Steel ASTM A193 B7M Threaded Rod

ASTM A193 B7M Double Ended Studs

ASTM A193 B7M Tap End Stud Bolt

Alloy Steel ASTM A193 B7M Tie Rods

Alloy Steel A193 Grade B7M Studs

SA 193 B7M Single End Stud Bolts

A193 Gr. B7M Reduced Shank Stud Bolt

A193 B7M Continuous Threaded Stud Bolt

A193 B7M Partial Threads Stud Bolt

SA193 / A193 B7M Heavy Stud Bolts

Raw Material of ASTM A193 Gr B7M Fasteners

Knowledge of the raw material, ASTM A193 Gr B7M fasteners, helps buyers to know that the products are durable and can work in extreme conditions.

| Grade | Raw Material Description |

|---|---|

| B7M | Chromium Molybdenum Alloy Steel, Quenched & Tempered |

Size Chart of A193 Grade B7M Stud Bolts

Having access to detailed size charts for A193 Grade B7M stud bolts helps buyers select the exact dimensions necessary for a secure and reliable fit.

| d | L is less than 6 b max | L is more than 6 b max | m max | m min |

|---|---|---|---|---|

| 1/4" | 0.8750 | 1.1250 | 0.2500 | 0.2127 |

| 5/16" | 1.0310 | 1.2810 | 0.3125 | 0.2712 |

| 3/8" | 1.1880 | 1.4380 | 0.3750 | 0.3287 |

| 7/16" | 1.3440 | 1.5940 | 0.4375 | 0.3850 |

| 1/2" | 1.5000 | 1.7500 | 0.5000 | 0.4435 |

| 9/16" | 1.6560 | 1.9060 | 0.5625 | 0.5016 |

| 5/8" | 1.8120 | 2.0620 | 0.6250 | 0.5589 |

| 3/4" | 2.1250 | 2.3750 | 0.7500 | 0.6773 |

| 7/8" | 2.4380 | 2.6880 | 0.8750 | 0.7946 |

| 1" | 2.7500 | 3.0000 | 1.0000 | 0.9100 |

| 1-1/8" | 3.0620 | 3.3120 | 1.1250 | 1.0228 |

| 1-1/4" | 3.3750 | 3.6250 | 1.2500 | 1.1476 |

| 1-3/8" | 3.6880 | 3.9280 | 1.3750 | 1.2563 |

| 1-1/2" | 4.0000 | 4.2500 | 1.5000 | 1.3812 |

Torque Chart of ASTM A193 Gr B7M Fasteners

The use of the torque chart of the ASTM A193 Gr B7M fasteners helps buyers to use appropriate tightening forces, which are important to the safety and durability.

| Bolt Size Inches or # |

Threads Per Inch | Standard Dry Torque in Inch-Pounds | |

|---|---|---|---|

| 304 Stainless Steel | 316 Stainless Steel | ||

| #2 | 56 | 2.5 | 2.6 |

| 64 | 3.0 | 3.2 | |

| #3 | 48 | 3.9 | 4.0 |

| 56 | 4.4 | 4.6 | |

| #4 | 40 | 5.2 | 5.5 |

| 48 | 6.6 | 6.9 | |

| #5 | 40 | 7.7 | 8.1 |

| 44 | 9.4 | 9.8 | |

| #6 | 32 | 9.6 | 10.1 |

| 40 | 12.1 | 12.7 | |

| #8 | 32 | 19.8 | 20.7 |

| 36 | 22.0 | 23.0 | |

| #10 | 24 | 22.8 | 23.8 |

| 32 | 31.7 | 33.1 | |

| 1/4 | 20 | 75.2 | 78.8 |

| 28 | 94.0 | 99.0 | |

| 5/16 | 18 | 132 | 138 |

| 24 | 142 | 147 | |

| 3/8 | 16 | 236 | 247 |

| 24 | 259 | 271 | |

| 7/16 | 14 | 376 | 393 |

| 20 | 400 | 418 | |

| 1/2 | 13 | 517 | 542 |

| 20 | 541 | 565 | |

| 9/16 | 12 | 682 | 713 |

| 18 | 752 | 787 | |

| 5/8 | 11 | 1110 | 1160 |

| 18 | 1244 | 1301 | |

| 3/4 | 10 | 1530 | 1582 |

| 16 | 1490 | 1558 | |

| 7/8 | 9 | 2328 | 2430 |

| 14 | 2318 | 2420 | |

| 1 | 8 | 3440 | 3595 |

| 14 | 3110 | 3250 | |

| Bolt Size Inches or # |

Threads Per Inch | Standard Dry Torque in Foot-Pounds | |

|---|---|---|---|

| 304 Stainless Steel | 316 Stainless Steel | ||

| 1 1/8 | 7 | 413 | 432 |

| 12 | 390 | 408 | |

| 1 1/4 | 7 | 523 | 546 |

| 12 | 480 | 504 | |

| 1 1/2 | 6 | 888 | 930 |

| 12 | 703 | 732 | |

A193 Grade B7M Hex Bolt Dimensions Metric

It is practical for buyers to know the metric dimensions of A193 Grade B7M hex bolts to ensure proper compatibility with equipment specifications.

| d | ds max | ds min | S nom | S min | E min | K nom | K max | K min |

|---|---|---|---|---|---|---|---|---|

| M1.6 | 1.6000 | 1.4600 | 3.2000 | 3.0200 | 3.4100 | 1.1000 | 1.2250 | 0.9750 |

| M2 | 2.0000 | 1.8600 | 4.0000 | 3.8200 | 4.3200 | 1.4000 | 1.5250 | 1.2750 |

| M2.5 | 2.5000 | 2.3600 | 5.0000 | 4.8200 | 5.4500 | 1.7000 | 1.8250 | 1.5750 |

| M3 | 3.0000 | 2.8600 | 5.5000 | 5.3200 | 6.0100 | 2.0000 | 2.1250 | 1.8750 |

| M4 | 4.0000 | 3.8200 | 7.0000 | 6.7800 | 7.6600 | 2.8000 | 2.9250 | 2.6750 |

| M5 | 5.0000 | 4.8200 | 8.0000 | 7.7800 | 8.7900 | 3.5000 | 3.6500 | 3.3500 |

| M6 | 6.0000 | 5.8200 | 10.0000 | 9.7800 | 11.0500 | 4.0000 | 4.1500 | 3.8500 |

| M8 | 8.0000 | 7.7800 | 13.0000 | 12.7300 | 14.3800 | 5.3000 | 5.4500 | 5.1500 |

| M10 | 10.0000 | 9.7800 | 16.0000 | 15.7300 | 17.7700 | 6.4000 | 6.5800 | 6.2200 |

| M12 | 12.0000 | 11.7800 | 18.0000 | 17.7300 | 20.0300 | 7.5000 | 7.6800 | 7.3200 |

| M16 | 16.0000 | 15.7300 | 24.0000 | 23.6700 | 26.7500 | 10.0000 | 10.1800 | 9.8200 |

| M20 | 20.0000 | 19.6700 | 30.0000 | 29.6700 | 33.5300 | 12.5000 | 12.7150 | 12.2850 |

| M24 | 24.0000 | 23.6700 | 36.0000 | 35.3800 | 39.9800 | 15.0000 | 15.2150 | 14.7850 |

| M30 | 30.0000 | 29.4800 | 46.0000 | 45.0000 | 50.8500 | 18.7000 | - | - |

| M36 | 36.0000 | 35.3800 | 55.0000 | 53.8000 | 60.7900 | 22.5000 | - | - |

| M42 | 42.0000 | 41.3800 | 65.0000 | 63.1000 | 71.3000 | 26.0000 | - | - |

| M48 | 48.0000 | 47.3800 | 75.0000 | 73.1000 | 82.6000 | 30.0000 | - | - |

| M56 | 56.0000 | 55.2600 | 85.0000 | 82.8000 | 93.5600 | 35.0000 | - | - |

| M64 | 64.0000 | 63.2600 | 95.0000 | 92.8000 | 104.8600 | 40.0000 | - | - |

SA 193 B7M Stud Bolt Metric Dimensions

Familiarity with the metric dimensions of SA 193 B7M stud bolts enables precise ordering and reliable fitment in metric-based systems.

| d | L is less than 6 b max | L is more than 6 b max | m max | m min |

|---|---|---|---|---|

| 1/4" | 0.8750 | 1.1250 | 0.2500 | 0.2127 |

| 5/16" | 1.0310 | 1.2810 | 0.3125 | 0.2712 |

| 3/8" | 1.1880 | 1.4380 | 0.3750 | 0.3287 |

| 7/16" | 1.3440 | 1.5940 | 0.4375 | 0.3850 |

| 1/2" | 1.5000 | 1.7500 | 0.5000 | 0.4435 |

| 9/16" | 1.6560 | 1.9060 | 0.5625 | 0.5016 |

| 5/8" | 1.8120 | 2.0620 | 0.6250 | 0.5589 |

| 3/4" | 2.1250 | 2.3750 | 0.7500 | 0.6773 |

| 7/8" | 2.4380 | 2.6880 | 0.8750 | 0.7946 |

| 1" | 2.7500 | 3.0000 | 1.0000 | 0.9100 |

| 1-1/8" | 3.0620 | 3.3120 | 1.1250 | 1.0228 |

| 1-1/4" | 3.3750 | 3.6250 | 1.2500 | 1.1476 |

| 1-3/8" | 3.6880 | 3.9280 | 1.3750 | 1.2563 |

| 1-1/2" | 4.0000 | 4.2500 | 1.5000 | 1.3812 |

A193 B7M Hex Nut Dimensions Metric

Understanding the metric dimensions of A193 B7M hex nuts allows buyers to confidently pair nuts with corresponding bolts for secure assemblies.

| d | s | e | m |

|---|---|---|---|

| M1.2 | 3.0000 | 3.2900 | 1.0000 |

| M1.4 | 3.0000 | 3.2900 | 1.2000 |

| M1.6 | 3.2000 | 3.4800 | 1.3000 |

| M1.7 | 3.5000 | 3.8200 | 1.4000 |

| M2 | 4.0000 | 4.3200 | 1.6000 |

| M2.3 | 4.5000 | 4.9500 | 1.8000 |

| M2.5 | 5.0000 | 5.4500 | 2.0000 |

| M2.6 | 5.0000 | 5.5100 | 2.0000 |

| M3 | 5.5000 | 6.0100 | 2.4000 |

| M3.5 | 6.0000 | 6.0100 | 2.8000 |

| M4 | 7.0000 | 7.6600 | 3.2000 |

| M5 | 8.0000 | 8.7600 | 4.0000 |

| M6 | 10.0000 | 11.0500 | 5.0000 |

| M7 | 11.0000 | 12.1200 | 5.5000 |

| M8 | 13.0000 | 14.3800 | 6.5000 |

| M10 | 17.0000 | 18.9000 | 8.0000 |

| M12 | 19.0000 | 21.1000 | 10.0000 |

| M14 | 22.0000 | 24.4900 | 11.0000 |

| M16 | 24.0000 | 26.7500 | 13.0000 |

| M18 | 27.0000 | 29.5600 | 15.0000 |

| M20 | 30.0000 | 32.9500 | 16.0000 |

| M22 | 32.0000 | 35.0300 | 18.0000 |

| M24 | 36.0000 | 39.5500 | 19.0000 |

| M27 | 41.0000 | 45.2000 | 22.0000 |

| M30 | 46.0000 | 50.8500 | 24.0000 |

| M33 | 50.0000 | 55.3700 | 26.0000 |

| M36 | 55.0000 | 60.7900 | 29.0000 |

| M39 | 60.0000 | 66.4400 | 31.0000 |

| M42 | 65.0000 | 71.3000 | 34.0000 |

| M45 | 70.0000 | 76.9500 | 36.0000 |

| M48 | 75.0000 | 82.6000 | 38.0000 |

| M52 | 80.0000 | 88.2500 | 42.0000 |

| M56 | 85.0000 | 95.0700 | 45.0000 |

| M60 | 90.0000 | 100.7200 | 48.0000 |

| M64 | 95.0000 | 106.3700 | 51.0000 |

| M68 | 100.0000 | 112.0200 | 54.0000 |

| M72 | 105.0000 | 117.6700 | 58.0000 |

| M76 | 110.0000 | 123.3200 | 61.0000 |

| M80 | 115.0000 | 128.9700 | 64.0000 |

| M85 | 120.0000 | 133.1100 | 68.0000 |

| M90 | 130.0000 | 145.7700 | 72.0000 |

| M95 | 135.0000 | 151.4200 | 76.0000 |

| M100 | 145.0000 | 162.7200 | 80.0000 |

| M110 | 155.0000 | 174.0200 | 88.0000 |

| M115 | 165.0000 | 185.3200 | 92.0000 |

| M120 | 170.0000 | 190.9700 | 96.0000 |

| M125 | 180.0000 | 202.2700 | 100.0000 |

| M130 | 185.0000 | 207.7500 | 104.0000 |

| M135 | 190.0000 | 213.4000 | 108.0000 |

| M140 | 200.0000 | 224.7000 | 112.0000 |

| M145 | 210.0000 | 236.0000 | 116.0000 |

| M150 | 210.0000 | 236.0000 | 120.0000 |

ASME SA 193 B7M Washer Dimensions

Knowing the ASME SA 193 B7M washer dimensions is key for buyers looking to maintain proper load distribution and joint integrity in bolted connections.

| d | s | e | m |

|---|---|---|---|

| M1.2 | 3.0000 | 3.2900 | 1.0000 |

| M1.4 | 3.0000 | 3.2900 | 1.2000 |

| M1.6 | 3.2000 | 3.4800 | 1.3000 |

| M1.7 | 3.5000 | 3.8200 | 1.4000 |

| M2 | 4.0000 | 4.3200 | 1.6000 |

| M2.3 | 4.5000 | 4.9500 | 1.8000 |

| M2.5 | 5.0000 | 5.4500 | 2.0000 |

| M2.6 | 5.0000 | 5.5100 | 2.0000 |

| M3 | 5.5000 | 6.0100 | 2.4000 |

| M3.5 | 6.0000 | 6.0100 | 2.8000 |

| M4 | 7.0000 | 7.6600 | 3.2000 |

| M5 | 8.0000 | 8.7600 | 4.0000 |

| M6 | 10.0000 | 11.0500 | 5.0000 |

| M7 | 11.0000 | 12.1200 | 5.5000 |

| M8 | 13.0000 | 14.3800 | 6.5000 |

| M10 | 17.0000 | 18.9000 | 8.0000 |

| M12 | 19.0000 | 21.1000 | 10.0000 |

| M14 | 22.0000 | 24.4900 | 11.0000 |

| M16 | 24.0000 | 26.7500 | 13.0000 |

| M18 | 27.0000 | 29.5600 | 15.0000 |

| M20 | 30.0000 | 32.9500 | 16.0000 |

| M22 | 32.0000 | 35.0300 | 18.0000 |

| M24 | 36.0000 | 39.5500 | 19.0000 |

| M27 | 41.0000 | 45.2000 | 22.0000 |

| M30 | 46.0000 | 50.8500 | 24.0000 |

| M33 | 50.0000 | 55.3700 | 26.0000 |

| M36 | 55.0000 | 60.7900 | 29.0000 |

| M39 | 60.0000 | 66.4400 | 31.0000 |

| M42 | 65.0000 | 71.3000 | 34.0000 |

| M45 | 70.0000 | 76.9500 | 36.0000 |

| M48 | 75.0000 | 82.6000 | 38.0000 |

| M52 | 80.0000 | 88.2500 | 42.0000 |

| M56 | 85.0000 | 95.0700 | 45.0000 |

| M60 | 90.0000 | 100.7200 | 48.0000 |

| M64 | 95.0000 | 106.3700 | 51.0000 |

| M68 | 100.0000 | 112.0200 | 54.0000 |

| M72 | 105.0000 | 117.6700 | 58.0000 |

| M76 | 110.0000 | 123.3200 | 61.0000 |

| M80 | 115.0000 | 128.9700 | 64.0000 |

| M85 | 120.0000 | 133.1100 | 68.0000 |

| M90 | 130.0000 | 145.7700 | 72.0000 |

| M95 | 135.0000 | 151.4200 | 76.0000 |

| M100 | 145.0000 | 162.7200 | 80.0000 |

| M110 | 155.0000 | 174.0200 | 88.0000 |

| M115 | 165.0000 | 185.3200 | 92.0000 |

| M120 | 170.0000 | 190.9700 | 96.0000 |

| M125 | 180.0000 | 202.2700 | 100.0000 |

| M130 | 185.0000 | 207.7500 | 104.0000 |

| M135 | 190.0000 | 213.4000 | 108.0000 |

| M140 | 200.0000 | 224.7000 | 112.0000 |

| M145 | 210.0000 | 236.0000 | 116.0000 |

| M150 | 210.0000 | 236.0000 | 120.0000 |

A193 Grade B7M Stud Bolts Weights

It benefits buyers to know the weights of A193 Grade B7M stud bolts for accurate logistics planning and cost management during procurement.

| Length | M12 | M16 | M20 | M22 | M24 | M27 | M30 | M36 |

|---|---|---|---|---|---|---|---|---|

| 30 | 49.1 | |||||||

| 35 | 53.6 | |||||||

| 40 | 58.0 | 105 | ||||||

| 45 | 62.1 | 113 | 188 | |||||

| 50 | 66.6 | 121 | 200 | 257 | ||||

| 55 | 71.0 | 129 | 212 | 272 | ||||

| 60 | 75.4 | 137 | 225 | 286 | 362 | |||

| 65 | 79.9 | 145 | 237 | 301 | 380 | |||

| 70 | 84.3 | 153 | 249 | 316 | 398 | 532 | ||

| 75 | 88.8 | 160 | 262 | 331 | 415 | 554 | 701 | |

| 80 | 93.2 | 168 | 274 | 346 | 433 | 576 | 728 | |

| 85 | 97.6 | 176 | 286 | 361 | 451 | 599 | 756 | 1184 |

| 90 | 102 | 184 | 298 | 375 | 467 | 621 | 784 | 1224 |

| 95 | 107 | 192 | 310 | 390 | 485 | 644 | 812 | 1264 |

| 100 | 199 | 322 | 405 | 503 | 665 | 838 | 1304 | |

| 105 | 207 | 335 | 420 | 520 | 688 | 865 | 1336 | |

| 110 | 215 | 347 | 435 | 538 | 710 | 893 | 1376 | |

| 115 | 223 | 359 | 450 | 556 | 732 | 921 | 1415 | |

| 120 | 231 | 372 | 465 | 574 | 755 | 949 | 1455 | |

| 125 | 239 | 384 | 479 | 591 | 777 | 976 | 1495 | |

| 130 | 247 | 396 | 494 | 609 | 800 | 1004 | 1535 | |

| 135 | 409 | 509 | 627 | 822 | 1032 | 1575 | ||

| 140 | 421 | 524 | 645 | 845 | 1059 | 1615 | ||

| 145 | 433 | 539 | 662 | 867 | 1087 | 1655 | ||

| 150 | 446 | 554 | 680 | 890 | 1115 | 1695 | ||

| 155 | 458 | 569 | 698 | 912 | 1143 | 1735 | ||

| 160 | 584 | 716 | 935 | 1170 | 1775 | |||

| 165 | 599 | 733 | 957 | 1198 | 1815 | |||

| 170 | 751 | 979 | 1226 | 1855 | ||||

| 175 | 769 | 1002 | 1254 | 1895 | ||||

| 180 | 787 | 1024 | 1281 | 1935 | ||||

| 185 | 804 | 1047 | 1309 | 1974 | ||||

| 190 | 822 | 1069 | 1337 | 2014 | ||||

| 195 | 840 | 1092 | 1365 | 2054 | ||||

| 200 | 1114 | 1392 | 2094 |

Applications of ASTM A193 Grade B7M Fasteners

- Petroleum Refineries and High-Pressure Steam Piping

- Chemical and Nitric Acid Processing Units

- Water and Sewage Treatment Plants

- Oil & Gas Pipelines and Offshore Equipment

- Pressure Vessels, Heat Exchangers, and Boilers

- Power Generation Plants

- Pump, Compressor, and Valve Assembly

- Industrial Fabrication and Heavy Engineering

ASTM A193 Grade B7M Fasteners Manufacturers, Suppliers & Exporters

Get the same value like never before with Unifit Fastener, your one-stop shop for ASTM A193 Gr B7M fasteners. We have integrated the best manufacturing excellence in the industry with 100% hardness testing, accuracy in quenching and tempering, and full chemical certification with the lowest market price.

The reason is that our minimum quantities of orders are flexible, on-the-fly production, and an international distribution channel ensures the timely delivery of the high quality of B7M bolts and studs. Unifit Fasteners: Stakeholders of superior quality, reliability and cost-efficiency in all their critical applications.

FAQ’s About ASTM A193 Gr B7M Fasteners

What is ASTM A193 Grade B7M material?

ASTM A193 Grade B7M is a heat-treated chromium-molybdenum alloy steel, manufactured with controlled hardness and improved ductility for high-pressure and high-temperature applications. It offers a minimum tensile strength of 100 ksi, a minimum yield strength of 75 ksi, and a maximum hardness of 99 HRB, making it suitable for demanding service conditions in chemical, petroleum, and industrial environments.

What is ASTM A193 used for?

ASTM A193 covers alloy and stainless-steel bolting materials specifically designed for high-pressure, high-temperature, and corrosive industrial service. These fasteners are widely used in refineries, power plants, chemical processing units, boilers, heat exchangers, and pressure vessels.

What is the material equivalent of ASTM A193 B7 in India?

In the Indian standards system, the closest equivalent to ASTM A193 Grade B7 is IS 1367 Grade 8.8 / 10.9 alloy steel fasteners, depending on the mechanical strength requirement. These grades offer similar tensile and yield properties suited for industrial bolting applications.

What is the difference between A193 B7 and B7M?

The difference between A193 B7 and B7M is that both are alloy steel grades under ASTM A193, but B7 fasteners have higher hardness and strength, while B7M fasteners are tempered to reduce hardness, enhance ductility, improve resistance to stress corrosion cracking, and are therefore preferred in corrosive chemical environments where controlled hardness and better weldability are required.